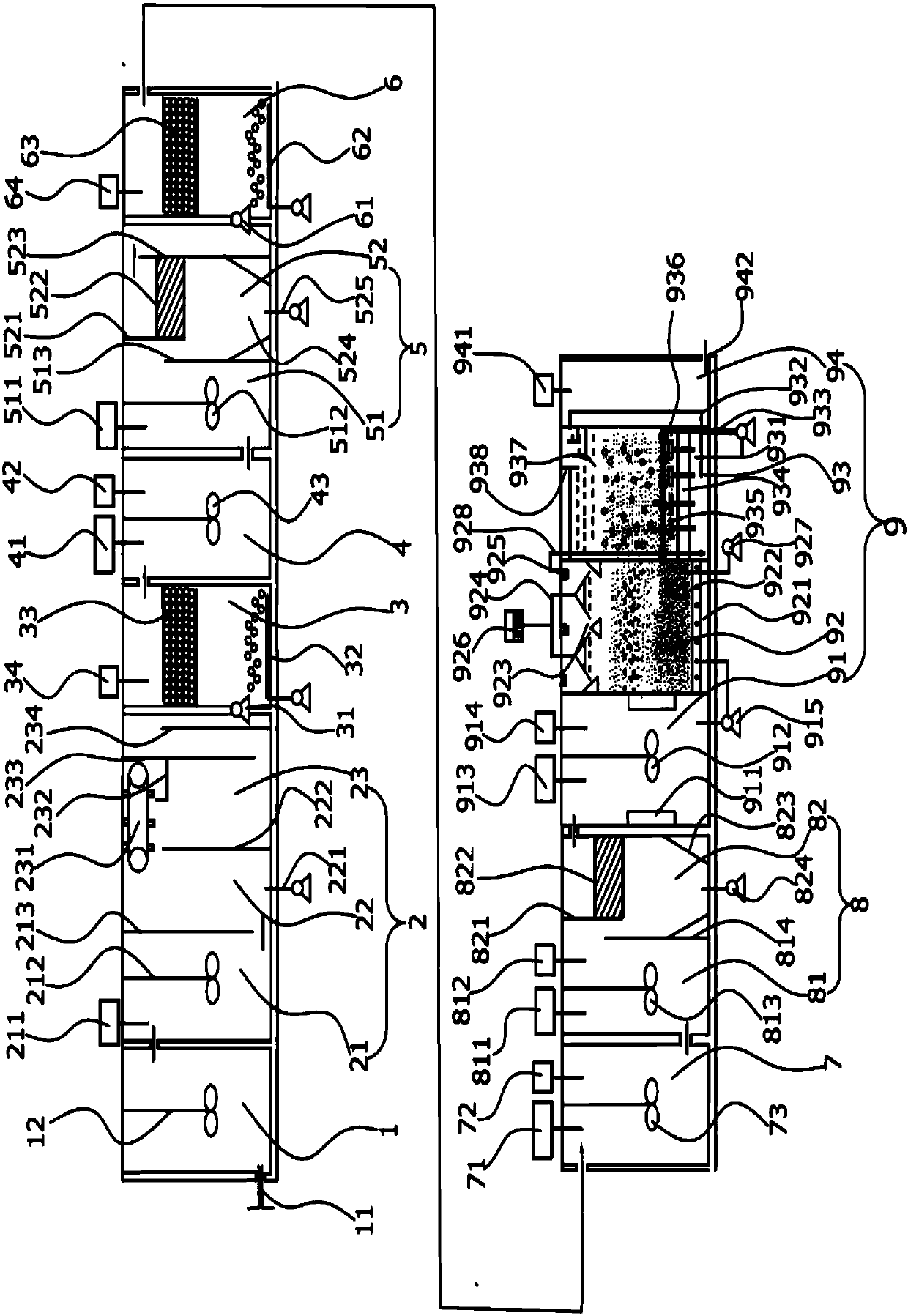

Method and device for carrying out integrated in-situ treatment on waste solvents

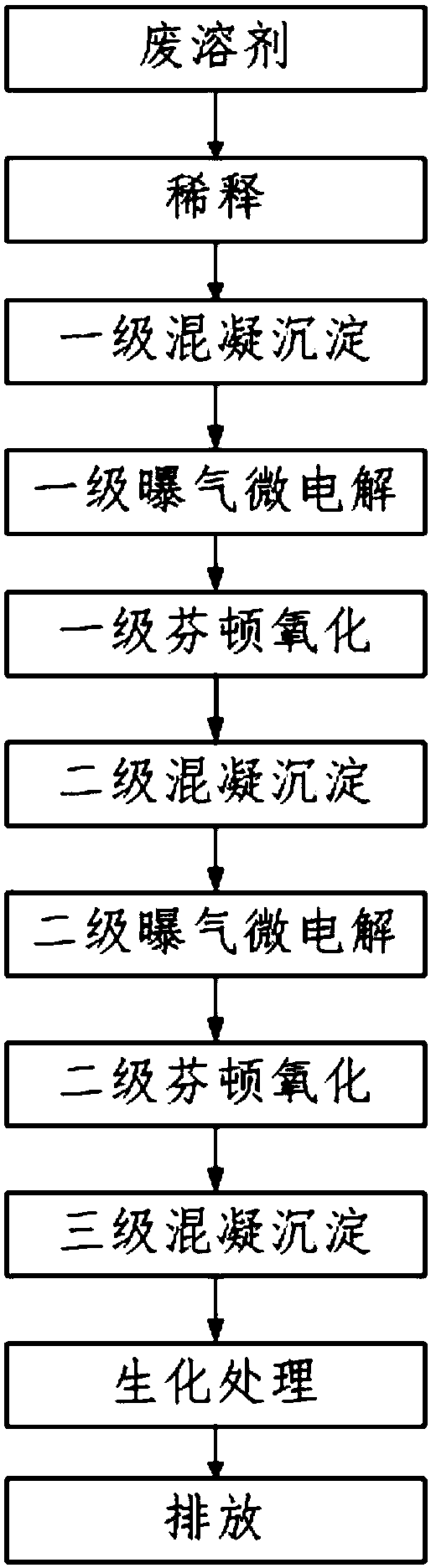

A technology for in-situ treatment and waste solvent, applied in the fields of metallurgical wastewater treatment, chemical instruments and methods, special compound water treatment, etc. Potential explosive safety hazards and the effect of improving biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

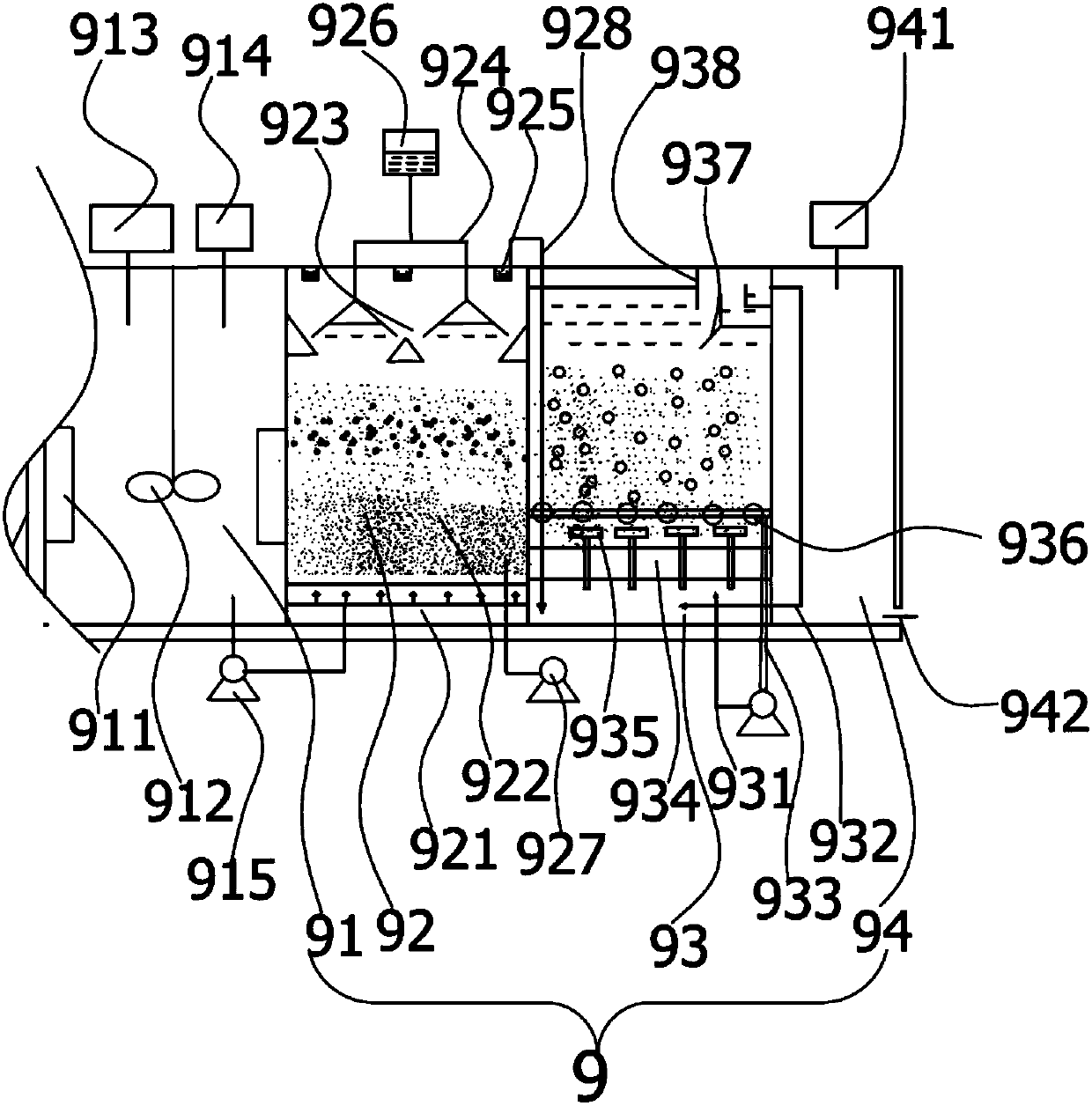

Embodiment 1

[0122] Waste solvent 50L, add water to dilute to 250L, test COD of waste solvent Cr =82540mg / L, BOD 5 =4700mg / L, BOD 5 / COD Cr =0.056, add 2‰ coagulant PAC (polyaluminum) through an automatic dosing device, stir for 20 minutes, and use an air flotation slag scraper to scrape slag. The first-level purification solvent enters the first-level aeration micro-electrolysis, adjusts pH = 2, Fe / C = 1:1, the volume ratio of the iron-carbon filler to the first-level purification solvent is 1:1, aeration micro-electrolysis for 2 hours, and the first-level purification The solvent enters the first-level Fenton oxidation treatment, adjusts pH = 2, adds 2‰ of 50% hydrogen peroxide, stirs for 0.5h, adds 2‰ coagulant PAM (polyacrylamide) through the automatic dosing device, stirs for 10min, and statically Set for 10min, test the CODcr=50800mg / L of the secondary purification solvent, BOD 5 =6560mg / L, BOD 5 / COD Cr = 0.13; the secondary purification solvent enters the secondary aeration m...

Embodiment 2

[0124] Waste solvent 50L, add water to dilute to 2500L, test COD of waste solvent Cr =8495mg / L, BOD 5 =500mg / L, BOD 5 / COD Cr =0.059 Add 3‰ coagulant PAC through the automatic dosing device, stir for 10 minutes, and use the air flotation slag scraper to scrape the slag. The first-level purification solvent enters the first-level aeration micro-electrolysis, adjusts pH = 2, Fe / C = 1:1, the volume ratio of iron-carbon filler to the first-level purification solvent is 4:3, aeration micro-electrolysis for 3 hours, and the first-level purification The solvent enters the first-level Fenton oxidation treatment, adjusts pH = 3, adds 8‰ of 50% hydrogen peroxide, stirs and reacts for 1 hour, adds 3‰ coagulant PAM through the automatic dosing device, stirs for 10 minutes, stands still for 10 minutes, and tests the second level CODcr of purified solvent=4983mg / L, BOD 5 =645mg / L, BOD 5 / COD Cr =0.129; the secondary purification solvent enters the secondary aeration micro-electrolysis...

Embodiment 3

[0126] Waste solvent 50L, add water to dilute to 1000L, test COD of waste solvent Cr =20810mg / L, BOD 5 =1201mg / L, BOD 5 / COD Cr =0.058; add 2‰ coagulant PAC through the automatic dosing device, stir for 20 minutes, and use the air flotation slag scraper to scrape the slag. The first-level purification solvent enters the first-level aeration micro-electrolysis, adjusts pH=3, Fe / C=7:3, the volume ratio of iron-carbon filler to the first-level purification solvent is 7:6, aeration micro-electrolysis for 2 hours, and the first-level purification The solvent enters the first-level Fenton oxidation treatment, adjusts pH=4, adds 50% hydrogen peroxide at 5‰, stirs and reacts for 1 hour, adds 2‰ coagulant PAM through the automatic dosing device, stirs for 20 minutes, stands still for 20 minutes, and tests the second level CODcr of purified solvent=10610mg / L, BOD 5 =1798mg / L, BOD 5 / COD Cr =0.17; the secondary purification solvent enters the secondary micro-electrolysis, adjusts p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com