Recovery and separation method for solvent containing tetrahydrofuran-carbinol system

A technology of tetrahydrofuran and methanol, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of large solvent loss and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

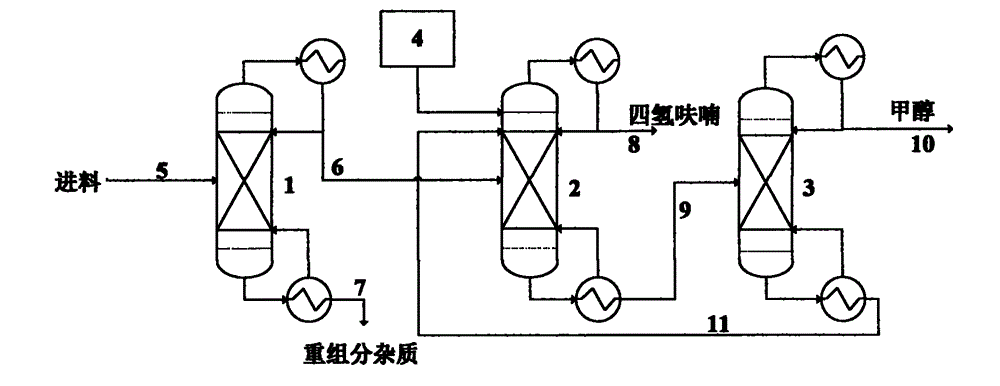

Method used

Image

Examples

Embodiment 1

[0022] There is a solvent composed of 20% methanol, 25% tetrahydrofuran, 54% water, and the rest are high-boiling impurities, which are added to the pretreatment tower at a rate of 200kg / hr. The number of plates in the pretreatment tower is 15, and the reflux ratio is 1.5 , The recovery rate at the top of the tower is 0.9 (relative to the feed), and the flow rate obtained is about 100kg / hr, and the mixed solution containing methanol-tetrahydrofuran-water enters the extractive distillation column. The number of plates in the extractive distillation column is 40, and the extraction agent ethylene glycol is added to the upper part of the column at a solvent ratio of 1:2 (solvent amount: extraction dose, mass ratio), and the reflux ratio is controlled to be 1-1.5, and the extraction at the top of the column is controlled. The ratio is 0.20-0.25 (relative to the feed), and the tower pressure is controlled at 1.5 atmospheres, so that a tetrahydrofuran product with a purity of more th...

Embodiment 2

[0024] There is a solvent composed of 10% methanol, 30% tetrahydrofuran, 59% n-heptane, and all the other high-boiling impurities, which are added to the pretreatment tower at a rate of 200kg / hr. The number of pretreatment tower plates is 17, and the reflux The ratio is 2.5, the recovery rate at the top of the tower is 0.4 (relative to the feed), and the flow rate is about 80kg / hr. The mixed solution containing methanol-tetrahydrofuran enters the extractive distillation tower, and the n-heptane product is obtained in the tower reactor. The number of plates in the extractive distillation column is 40, and the extraction agent ethylene glycol is added to the upper part of the column at a solvent ratio of 1:1.5 (solvent amount: extraction amount, mass ratio), and the reflux ratio is controlled to be 1-1.5, and the extraction at the top of the column is controlled. The ratio is 0.25-0.3 (relative to the feed), and the tower pressure is controlled at 1.5 atmospheres, so that a tetra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com