Waste solvent recovery system and method

A recovery system and recovery method technology, applied in the field of waste solvent recovery system, can solve the problems of low product purity, waste solvent doped with impurities, etc., and achieve the effects of high purity and precision, reduced impurity content, and high use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This embodiment provides a waste solvent recovery system, which can process and recover the waste solvent, and the purity of the product obtained after the waste solvent treatment is relatively high.

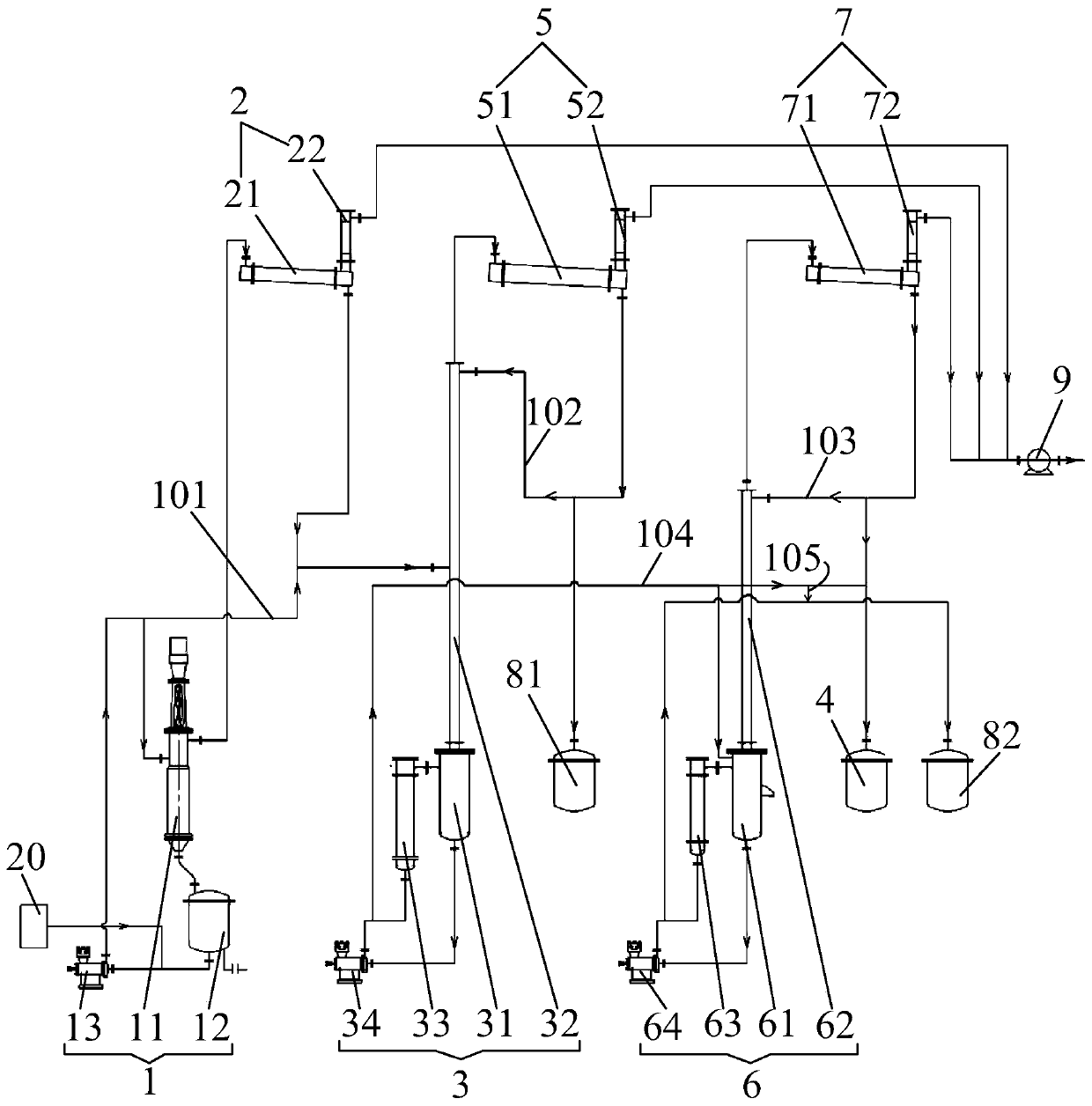

[0044] Such as figure 1 As shown, the waste solvent recovery system includes a thin film evaporation device 1, a first condensation device 2, a first distillation tower 3, a product tank 4, a second condensation device 5, and a first liquid receiving tank 81.

[0045] Wherein, the inlet of the thin film evaporation device 1 is in communication with the waste liquid device 20 containing waste solvent, and the thin film evaporation device 1 is used to remove high-boiling impurities, such as solid impurities, in the waste solvent. The inlet of the first condensing device 2 is communicated with the first outlet of the thin film evaporation device 1 so that the low boiling point substances in the thin film evaporation device 1 can enter the first condensing device 2. The first outl...

Embodiment 2

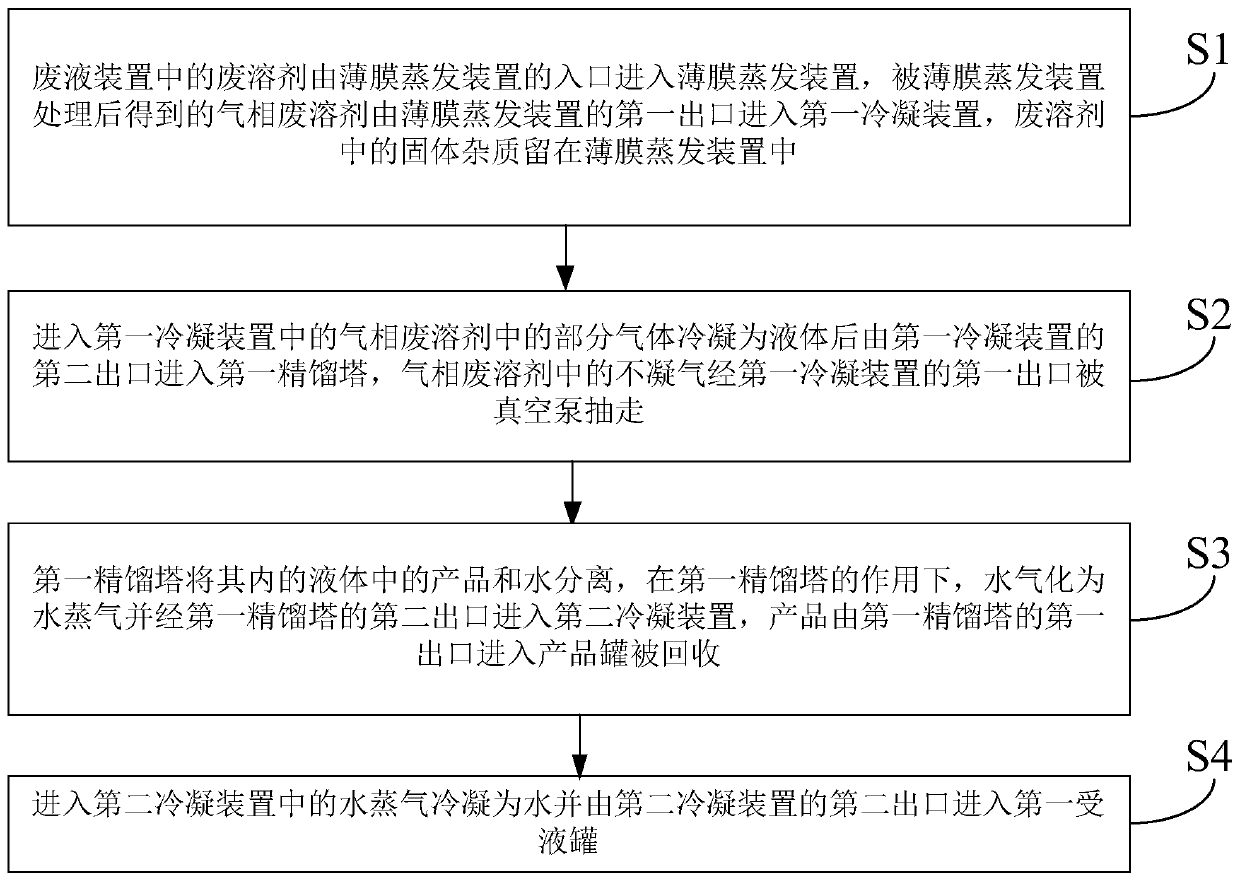

[0072] This embodiment also provides a waste solvent recovery method, which can be applied to the waste solvent recovery system in the first embodiment, such as figure 2 As shown, the waste solvent recovery method includes the following steps:

[0073] S1. The waste solvent in the waste liquid device enters the thin film evaporation device from the inlet of the thin film evaporation device, and the gas phase waste solvent obtained after being processed by the thin film evaporation device enters the first condensing device from the first outlet of the thin film evaporation device. The solids in the waste solvent Impurities remain in the thin film evaporation device.

[0074] S2. Part of the gas in the gas phase waste solvent entering the first condensing device is condensed into liquid and then enters the first rectification tower from the second outlet of the first condensing device, and the non-condensable gas in the gas phase waste solvent passes through the first condensing dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com