Method for recovering and purifying propylene glycol monomethyl ether and propylene glycol monomethyl ether acetate from electronic waste liquid

A technology of propylene glycol monomethyl ether acetate and propylene glycol monomethyl ether, which is applied in the field of solvent recovery and purification, can solve the problems of resource waste, high post-cost, and increased environmental load, and achieve production cost saving, simple production process, The effect of reducing the degree of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

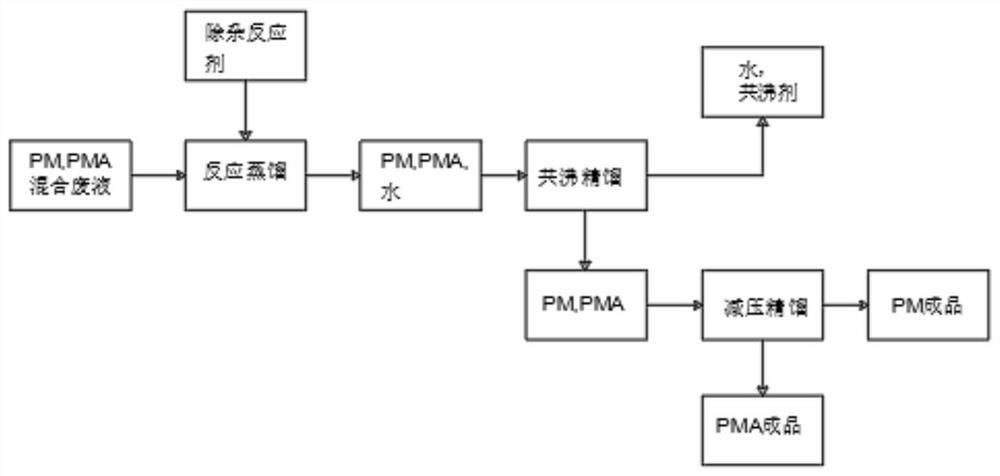

[0026] Take waste material containing 45% propylene glycol monomethyl ether, 54% propylene glycol monomethyl ether acetate, 4% water, and 1% cyclohexanone. Add the ethanolamine of 1:1 with cyclohexanone substance therein;

[0027] The propylene glycol monomethyl ether and propylene glycol monomethyl ether acetate obtained after the above reaction are added to the entrainer n-hexane for azeotropic distillation; the top of the tower obtains the n-hexane water azeotrope, and the bottom of the tower obtains propylene glycol monomethyl ether, propylene glycol Monomethyl ether acetate mixed solvent.

[0028] The above-mentioned propylene glycol monomethyl ether, propylene glycol monomethyl ether acetate, and n-hexane water azeotrope were separated for 30 minutes, and the upper layer was returned to the system for recycling as an azeotropic entrainer. The lower layer is discharged as waste water.

[0029] The mixed solvent of propylene glycol monomethyl ether and propylene glycol m...

Embodiment 2

[0031] Take waste material containing 35% propylene glycol monomethyl ether, 64% propylene glycol monomethyl ether acetate, 4% water, and 1% cyclohexanone. Add ethanolamine and cyclohexanone substance mass 1:1 therein.

[0032] The propylene glycol monomethyl ether and propylene glycol monomethyl ether acetate obtained after the above reaction are added to the entrainer n-hexane for azeotropic distillation; the top of the tower obtains the n-hexane water azeotrope, and the bottom of the tower obtains propylene glycol monomethyl ether, propylene glycol Monomethyl ether acetate mixed solvent.

[0033] The above-mentioned propylene glycol monomethyl ether, propylene glycol monomethyl ether acetate, and n-hexane water azeotrope were separated for 30 minutes, and the upper layer was returned to the system for recycling as an azeotropic entrainer. The lower layer is discharged as waste water.

[0034] The mixed solvent of propylene glycol monomethyl ether and propylene glycol mono...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com