Recovery method of N, N-dimethylacetamide

A technology of dimethylacetamide and a recovery method, which is applied in the field of chemical waste solvent recovery, can solve the problems of higher requirements for raw materials, blockage of membranes, limitation of universality of processing solvents, etc., and achieves the effect of process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

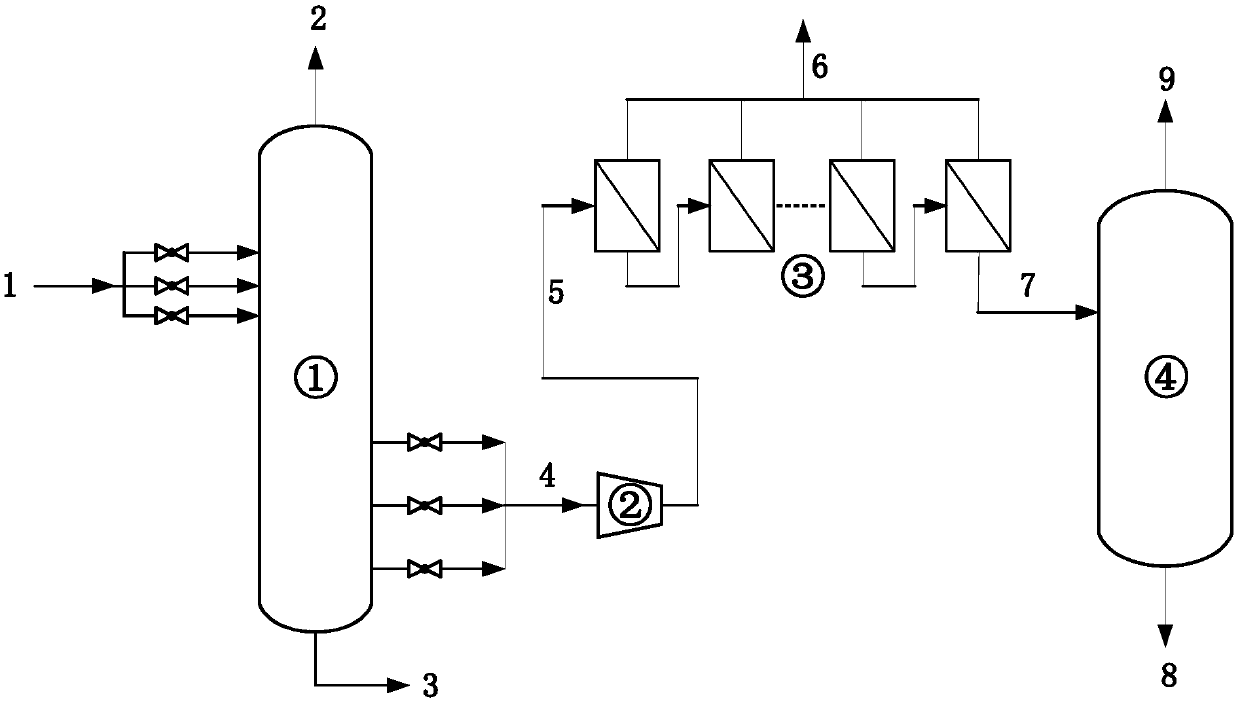

Embodiment 1

[0029] A batch of waste water solvent containing 2% N,N-dimethylacetamide, the pH value is adjusted to between 6 and 8 by sodium carbonate, and then enters the distillation tower for preliminary concentration and removal of impurities. The operating pressure of the distillation tower is 1 atm. The reflux ratio is 0.5, and the temperature at the top of the tower is controlled at 100°C. The concentrated product is extracted through the side stream vapor phase, and the temperature of the extracted vapor phase material is 125° C., wherein the mass fraction of N,N-dimethylacetamide is 55%. After being pressurized to 4atm by the compressor, the temperature rises to 150°C, and it directly enters the membrane separation module for further dehydration and concentration. Four-stage membrane separation and dehydration are used, and the pressure on the permeate side is controlled at 1kPa. The obtained concentrate is sent to the refining tower for further dehydration. The operating pressur...

Embodiment 2

[0031] A batch of waste water solvent containing 5% N,N-dimethylacetamide is adjusted to a pH value between 6 and 8 by sodium carbonate, and then enters a distillation tower for initial concentration and removal of impurities. The operating pressure of the distillation tower is 1 atm. The reflux ratio is 0.5, and the temperature at the top of the tower is controlled at 100°C. The concentrated product is withdrawn through the side stream vapor phase, the temperature of the withdrawn vapor phase material is 122°C, and the mass fraction of N,N-dimethylacetamide is 50%. After being pressurized to 4atm by the compressor, the temperature rises to 149°C, and it directly enters the membrane separation module for further dehydration and concentration, using 5-stage membrane separation and dehydration, and the pressure on the permeate side is controlled at 1kPa. The obtained concentrate was sent to the refining tower for further dehydration. The operating pressure of the refining tower ...

Embodiment 3

[0033] A batch of waste water solvent containing 10% N,N-dimethylacetamide is adjusted to a pH value between 6 and 8 by sodium carbonate, and then enters a distillation tower for initial concentration and removal of impurities. The operating pressure of the distillation tower is 1 atm. The reflux ratio is 0.5, and the temperature at the top of the tower is controlled at 100°C. The concentrated product is extracted through the side stream vapor phase, and the temperature of the extracted vapor phase material is 128° C., wherein the mass fraction of N,N-dimethylacetamide is 60%. After being pressurized to 4atm by the compressor, the temperature rises to 152°C, and it directly enters the membrane separation module for further dehydration and concentration. Three-stage membrane separation and dehydration are used, and the pressure on the permeate side is controlled at 1kPa. The obtained concentrate is sent to the refining tower for further dehydration. The operating pressure of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com