Light polymer-based nano composite material for absorbing X-band electromagnetic waves, and preparation method thereof

A technology of nanocomposite materials and polymers, which is applied in the field of lightweight polymer-based nanocomposites and can solve problems such as heavy weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1) Put PS resin (thermoplastic resin B) and PMMA resin (thermoplastic resin A) in an oven and dry at 60°C for 24 hours for later use.

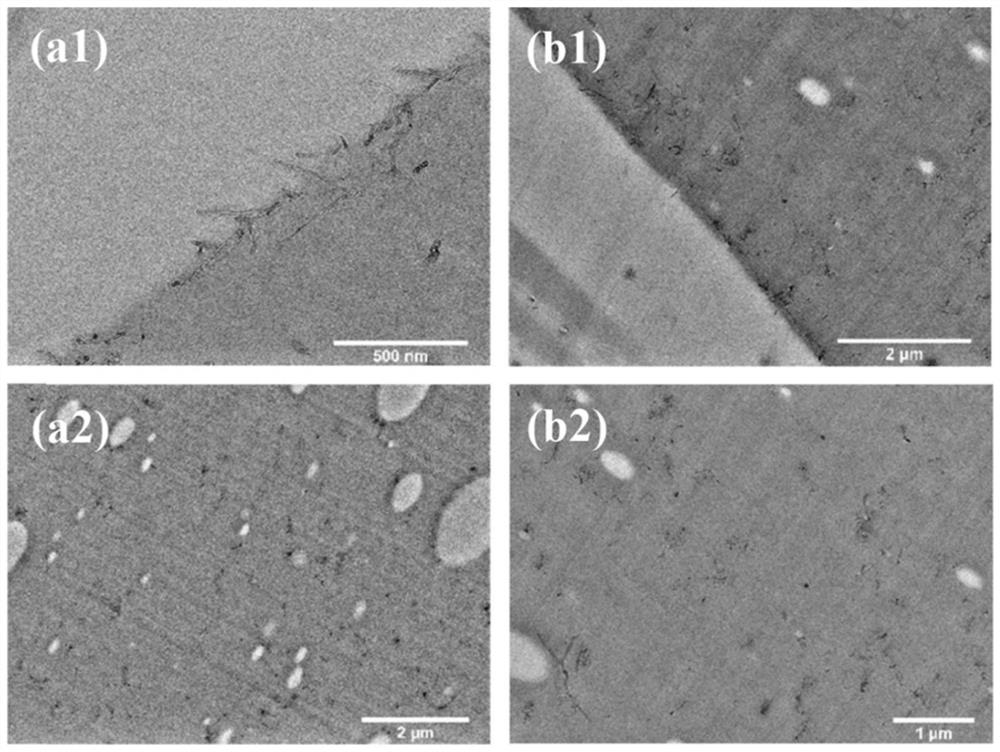

[0038] 2) Before the melt mixing process, the PMMA resin is crushed into fine particles using a crusher and fully dried, and 1 wt% carbon nanotube (MWCNT) is weighed and fully ground and premixed with the dried PMMA resin in a mortar.

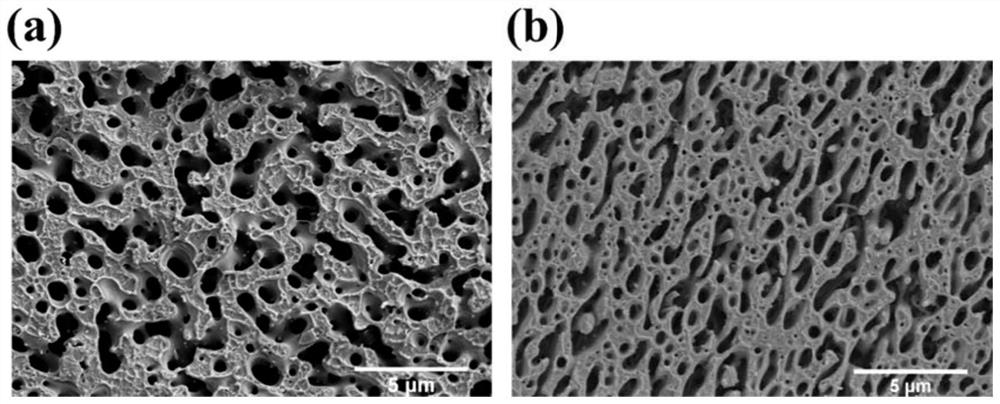

[0039] 3) Use a miniature high-performance composite material hybrid molding system (HAAKE Minilab II) for melt mixing, set the temperature at 200°C, screw speed at 60 rpm, and melt mix for 20 minutes to fully and uniformly mix the carbon nanotubes and PMMA resin to obtain the matrix Material I (referred to as PMMA-MWCNT).

[0040] 4) Use a miniature high-performance composite material hybrid molding system (HAAKE Minilab II) for melt mixing, set the temperature at 200 ° C, and screw speed at 60 rpm, mix masterbatch I with PS resin, and the volume ratio of the two mixed is 50 / 50, to build a "double-com...

Embodiment 2

[0051] The preparation method of the polymer-based nanocomposite material in this embodiment is the same as in Example 1, only the melt mixing time in step 4) becomes 5 minutes, and the polymer-based nanocomposite material finally obtained is denoted as PMMA-MWCNT / PS -2.

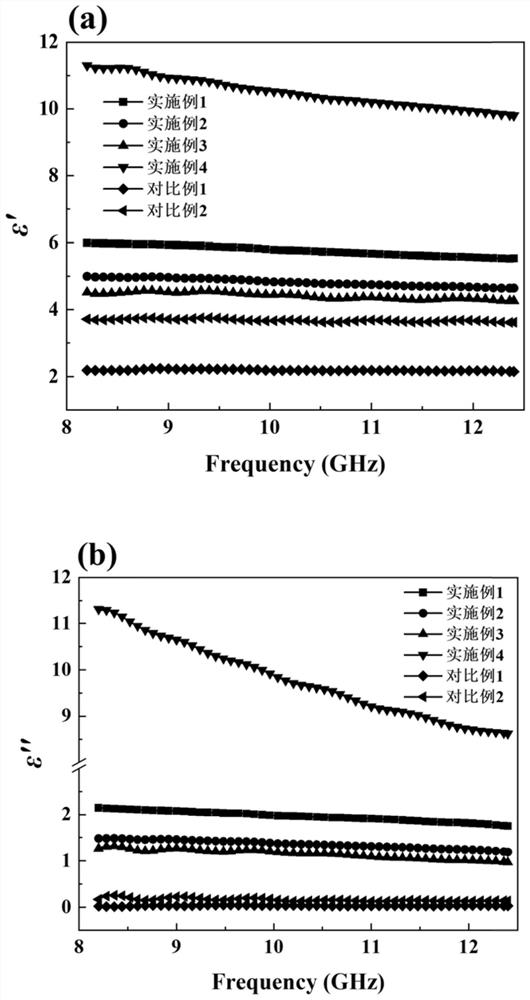

[0052] The obtained composite material was subjected to the same measurement of dielectric properties and calculation of absorbing properties as in Example 1.

[0053] Calculation results: When the RL value is lower than -10dB, the absorption of electromagnetic waves exceeds 90%, which has practical application value. When the composite material (PMMA-MWCNT / PS-1) has a thickness of 2 mm, the bandwidth of electromagnetic wave absorption exceeding 90% is 8.2-9.0 GHz, which is reduced compared with Example 1, but still within the effective range. This is because the conductive network on the carbon nanotube interface is reduced due to migration, and the conduction loss caused by the local leakage conduction cu...

Embodiment 3

[0055] 1) Put PVDF resin (thermoplastic resin B) and PA6 resin (thermoplastic resin A) in an oven and dry at 60°C for 24 hours for later use.

[0056] 2) Before the melt mixing process, the PA6 resin is crushed into fine particles with a crusher, and 1 wt% carbon nanotube (MWCNT) is weighed and fully ground and premixed with the dried PA6 resin in a mortar.

[0057] 3) Use a miniature high-performance composite material hybrid molding system (HAAKE MinilabⅡ) for melt mixing, set the temperature at 220°C, screw speed at 60 rpm, and melt mix for 20 minutes to fully and uniformly mix carbon nanotubes and PVDF resin to obtain the matrix Material I (marked as PA6-MWCNT).

[0058] 4) Use a miniature high-performance composite material hybrid molding system (HAAKE Minilab II) for melt mixing, set the temperature at 200 ° C, and screw speed at 60 rpm, mix masterbatch I with PVDF resin, and the volume ratio of the two mixed is 50 / 50, in order to construct the "two-communication" form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com