Circuit structure of a laboratory ultrasonic biological treatment system

A technology of biological processing and circuit structure, applied in the methods of stress-stimulated growth of microorganisms, biochemical equipment and methods, electrical components, etc. It can reduce the space occupation of the body, realize automatic storage, and improve the utilization rate of detection points.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

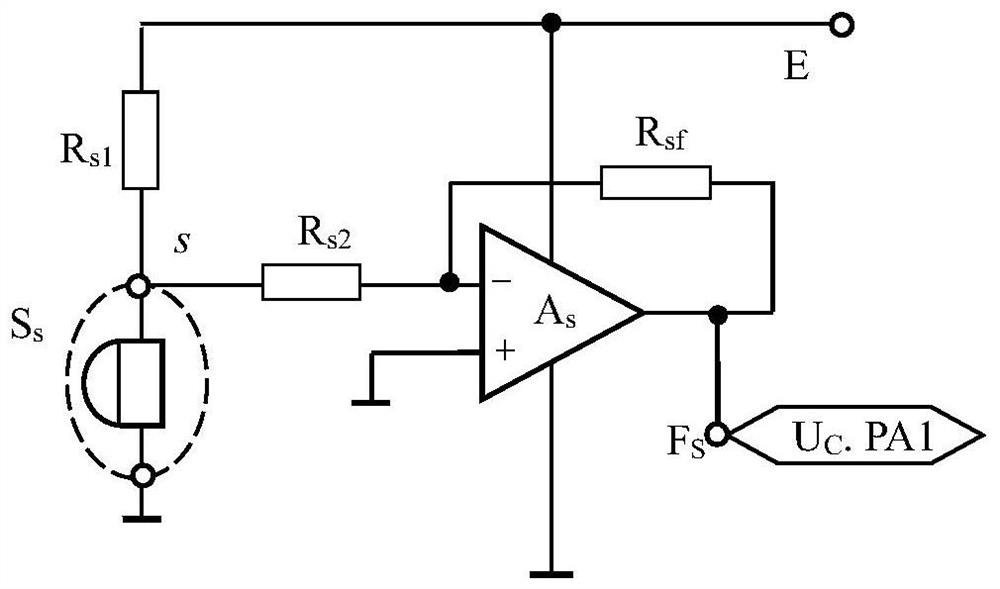

[0037] exist figure 1 In the structural diagram of the sound intensity detection feedback circuit of the processing tank shown in the figure: the sound intensity detection feedback circuit of the processing tank is based on the sound intensity sensor S s It is the sound intensity detection feedback circuit of the core device. Sound intensity signal bias current resistance R s1 One end of the control circuit is connected to the positive terminal E of the working power supply of the control circuit, and the other end is connected to the sound intensity sensor S of the sound measuring part 14.8 s The output terminal of the sound intensity signal s; the sound intensity sensor S s The ground terminal is grounded. Sound Intensity Sensor S s The output terminal of the sound intensity signal s passes through the sound intensity signal coupling resistor R s2 The sound intensity signal op amp connected to A s Inverting input terminal; sound intensity signal op amp A s The non-inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com