NOFBX thrust chamber based on micro-channel regenerative cooling technology

A regenerative cooling, micro-channel technology, applied in jet propulsion devices, rocket engine devices, machines/engines, etc., can solve problems such as the inability to meet the cooling requirements of NOFBX combustion chambers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

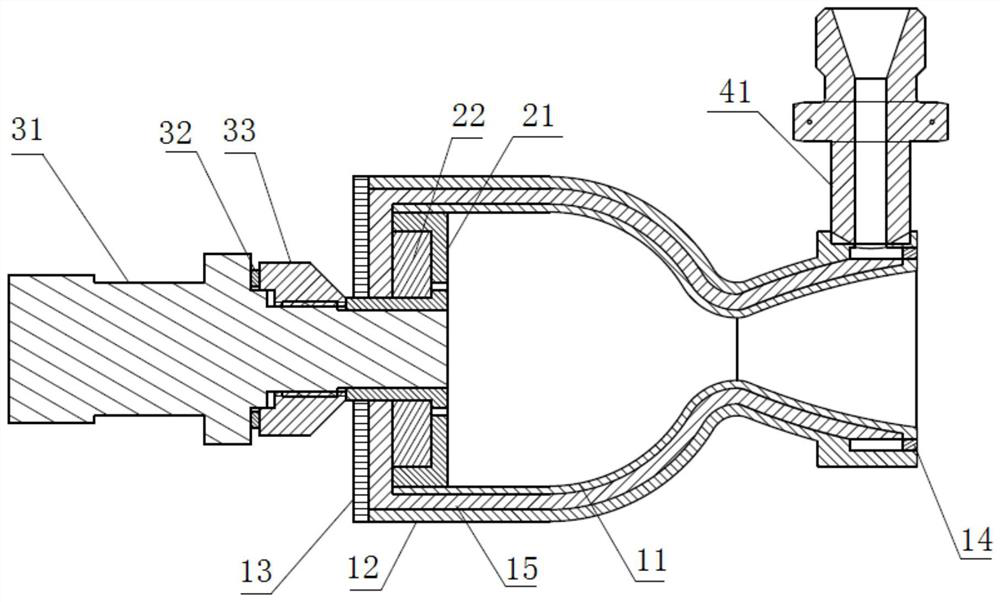

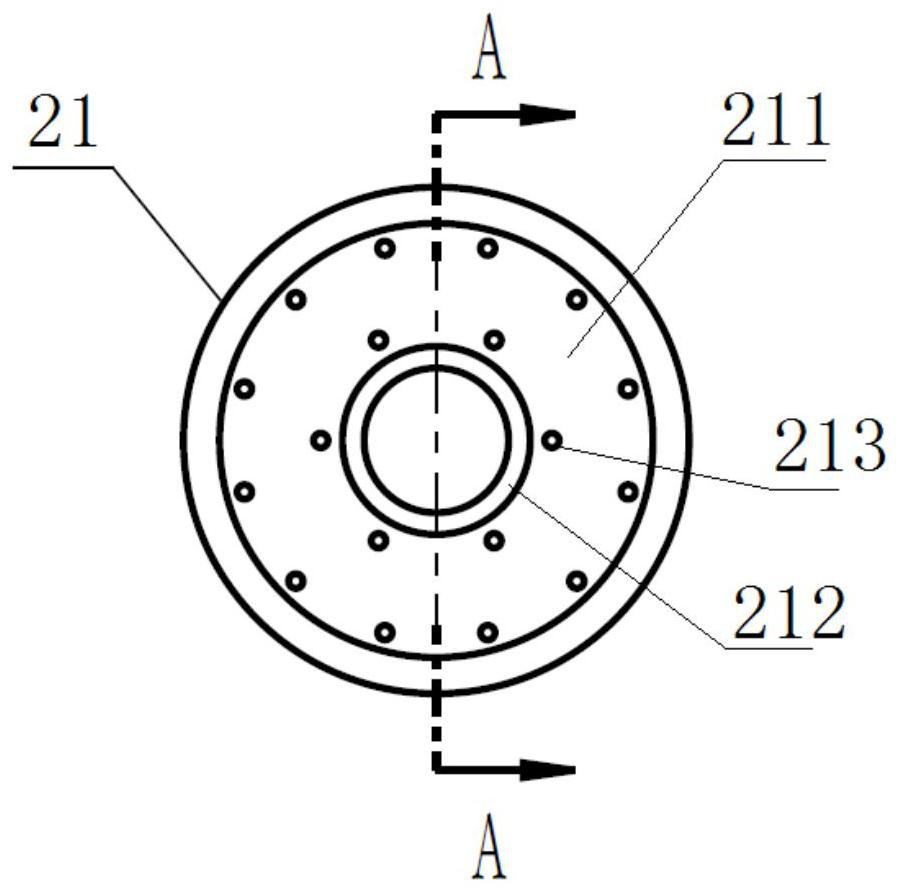

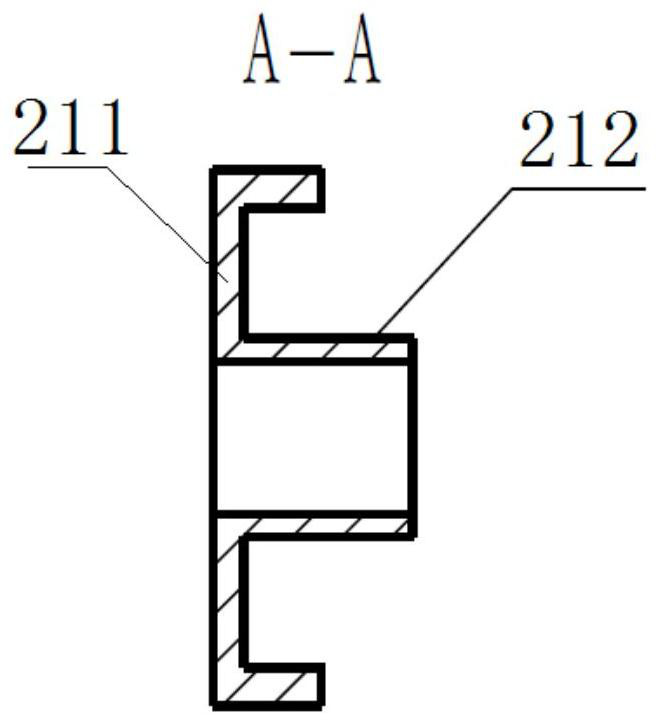

[0032] In order to make the purpose, advantages and features of the present invention clearer, a NOFBX thrust chamber based on microchannel regenerative cooling technology proposed by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0033] The NOFBX thrust chamber based on the microchannel regenerative cooling technology provided by this embodiment is as follows: figure 1 As shown, the combustion chamber, injector, spark plug 31 and propellant inlet conduit 41 are included.

[0034] The combustion chamber includes an inner casing 11 , an outer casing 12 , a cover plate 13 and an annular blocking cover 14 . The inner shell 11 and the outer shell 12 are set coaxially, and their rear ends are flush with each other. A first channel is formed between the inner shell 11 and the outer shell 12 . The cover plate 13 is fixedly installed at the opening of the front end of the outer shell 12 , and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com