Reinforced concrete corrosion monitoring equipment

A reinforced concrete and corrosion monitoring technology, applied in the field of monitoring systems, can solve problems such as large deviation of results, low monitoring efficiency, and susceptibility to humidity and ion concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

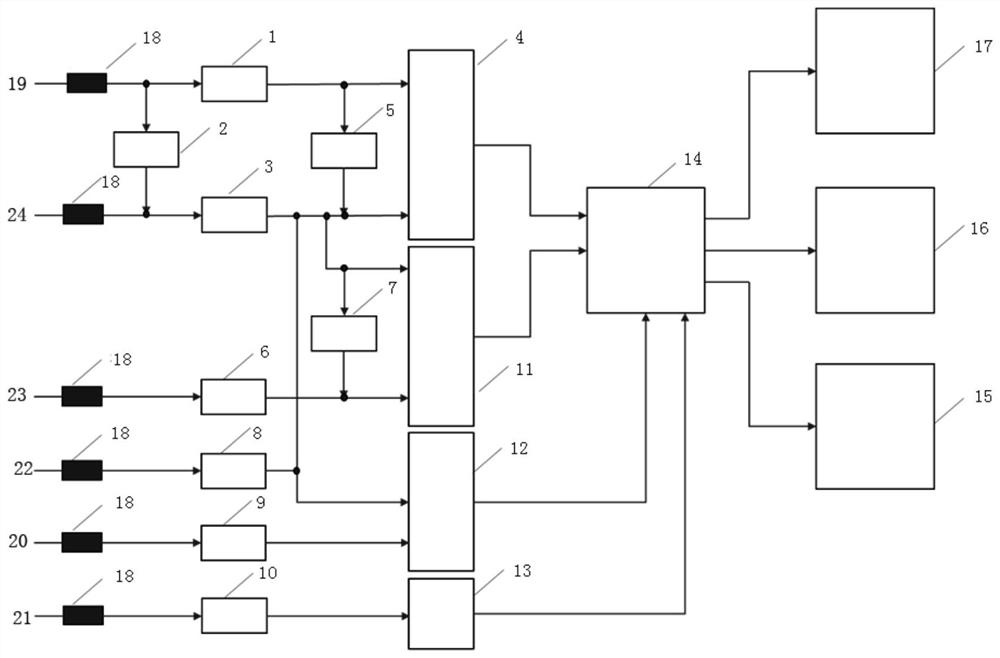

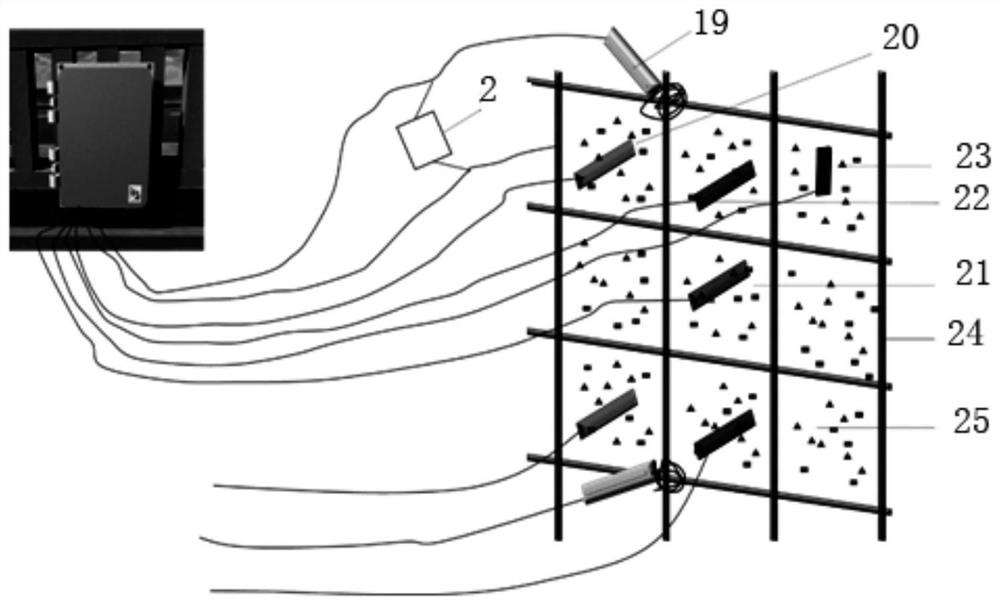

[0029] Embodiment: a reinforced concrete corrosion monitoring device, comprising an anti-corrosion electric block 19, a first relay switch 2, a long-term reference electrode 20, an anode current monitoring module 4, a potential monitoring module 12, a thermocouple 21, and a thermocouple temperature detection Module 13, chlorine ion sensor 22, positioning module 16, wireless communication module 15, system main control module 14, server and power supply device;

[0030] The anti-corrosion electric block 19, the long-term reference electrode 20, the chloride ion sensor 22 and the thermocouple 21 are all buried in the reinforced concrete 24, and one end of the anti-corrosion electric block 19 and one end of the steel bar 24 in the reinforced concrete 25 pass through the circuit connected to form a parallel working state, and a series circuit is also provided, and the series circuit connects the other end of the anti-corrosion electric block 19 with the other end of the steel bar 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com