Noise reduction plate structure and transformer box body structure

A technology of noise reduction board and transformer, which is applied in the direction of transformer/inductor casing, transformer/inductor noise damping, etc., which can solve the problems of high development cost, poor pressure resistance performance, and poor noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

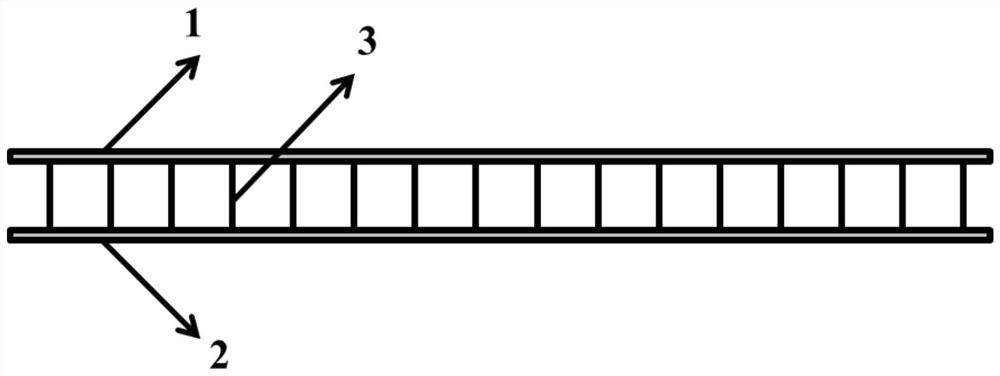

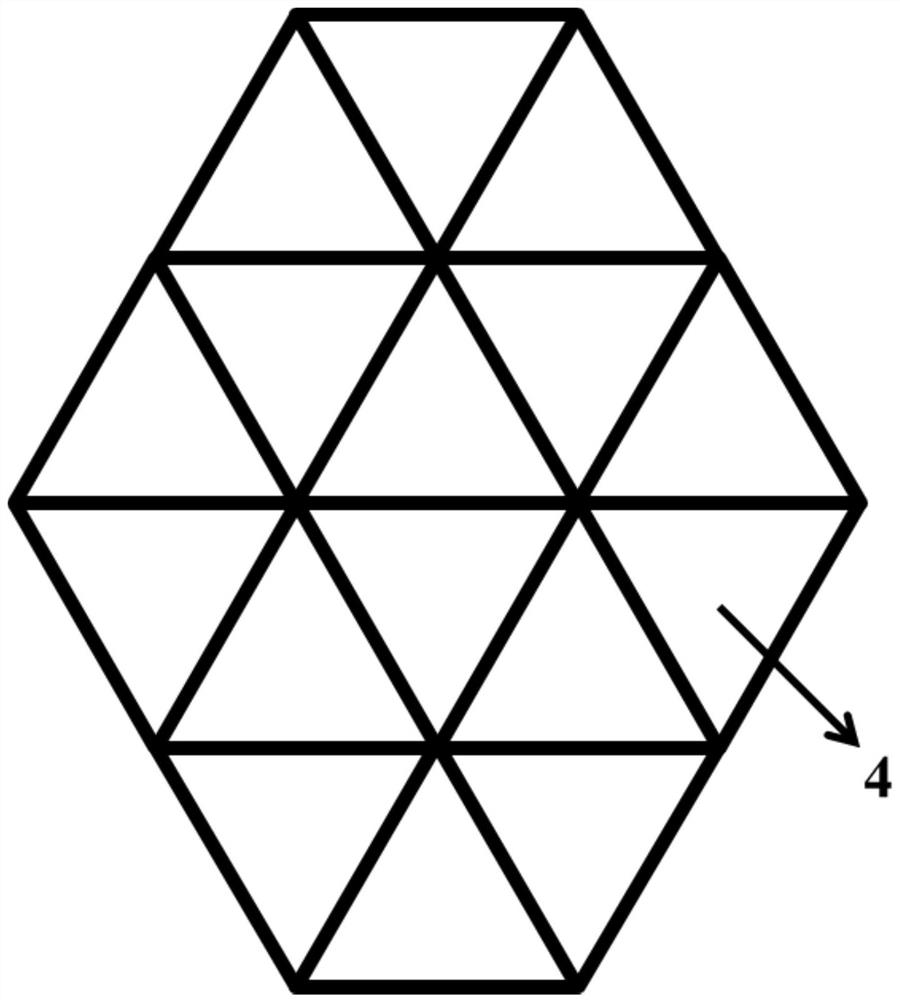

[0027] The invention provides a transformer box structure, such as figure 1 As shown, the upper panel 1 and the lower panel 2 of the wall panel sandwich noise reduction structure are made of steel plates, and the honeycomb core layer 3 is made of carbon fiber reinforced material (CFRP), such as figure 2 As shown, the shape of the honeycomb adopts an equilateral triangle honeycomb 4, the direction of the honeycomb is selected as the honeycomb is perpendicular to the panel, the quality of the panel and the honeycomb core layer is distributed according to the upper panel 1: the honeycomb core layer 3: the lower panel 2 is 1:1:1, and the height of the honeycomb is selected 30mm, the panel and the honeycomb core layer 3 are connected by glue. These designs can not only ensure that the overall structure of the panel sandwich has sufficient mechanical strength, stability, and safety, but also greatly improve its sound insulation performance, can significantly reduce transformer nois...

Embodiment 2

[0045] The noise-reducing structure of honeycomb wall panels for transformers adopts a three-layer structure. Both the upper panel 1 and the lower panel 2 are made of steel plates, and the middle honeycomb core layer 3 is made of carbon fiber reinforced material (CFRP). This structure has good sound insulation performance. And as a low-noise transformer box material, it has sufficient mechanical strength, stability and safety. The upper panel 1 and the lower panel 2 are connected with the honeycomb core layer 3 by glue, so that the manufacturing process is simple, safe, reliable, low in cost, and has significant direct and indirect benefits.

[0046] The honeycomb shape that the invention relates to adopts equilateral triangle honeycomb 4.

[0047] The direction of the cells of the honeycomb core layer 3 involved in the invention is selected so that the cells are perpendicular to the panel.

[0048] The quality of the upper panel 1 and lower panel 2 and the honeycomb core lay...

Embodiment 3

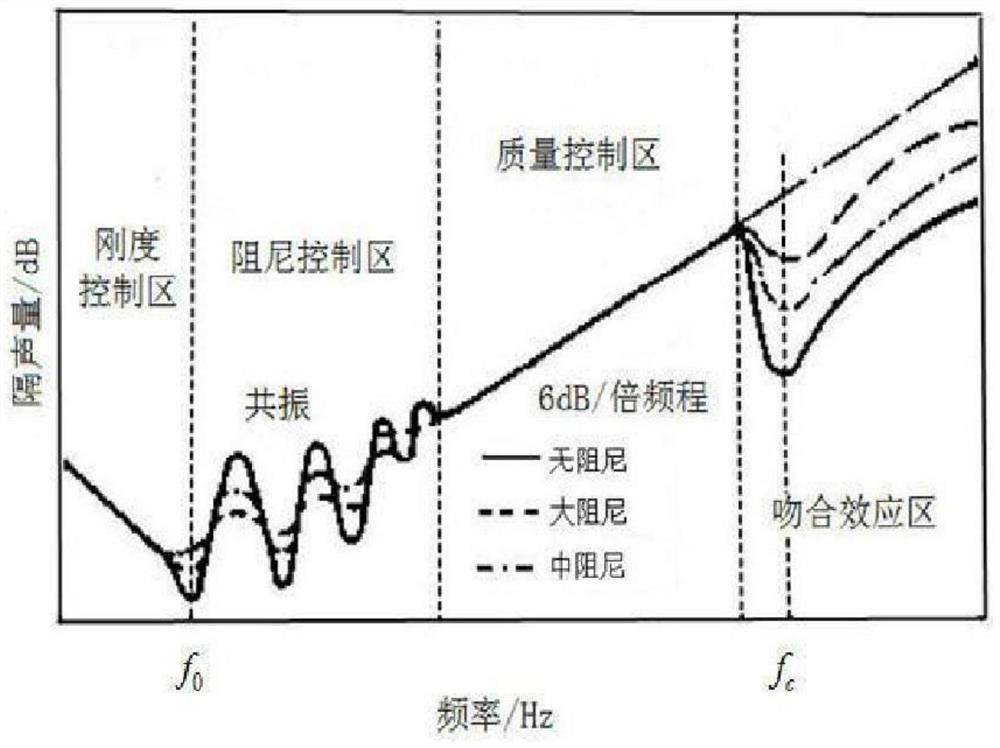

[0052] For a single-layer homogeneous plate, if it is assumed that: the sound wave is incident perpendicular to the plate; the plate is infinite and both sides of the plate are air; the influence of the plate boundary is not considered; the rigidity and damping of the plate are not considered; each particle on the plate is the same Velocity vibration, then, the sound insulation of the board TL 0 Approximate:

[0053] TL 0 =20lgm+20lgf-43dB

[0054] Among them, m is the mass per unit area of the plate, and f is the frequency of the incident sound wave.

[0055] In practice, single-layer homogeneous plates have a certain stiffness, and will undergo forced bending vibration after being excited by sound waves. When the forced bending wave propagation velocity of the plate is equal to its inherent free bending wave propagation velocity, the incident acoustic energy can be transmitted to the other side of the plate in large quantities. This effect is called the coincidence effe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com