Magnetic gathering type magnetic coupler

A magnetic coupler and magnetic focusing technology, applied in the direction of permanent magnet clutch/brake, electric brake/clutch, electrical components, etc., can solve the problem that the rotation speed is easily affected by the load and the environment, and the transmission ratio of the motor and the working machine cannot be accurate. Control, slow response of the working machine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

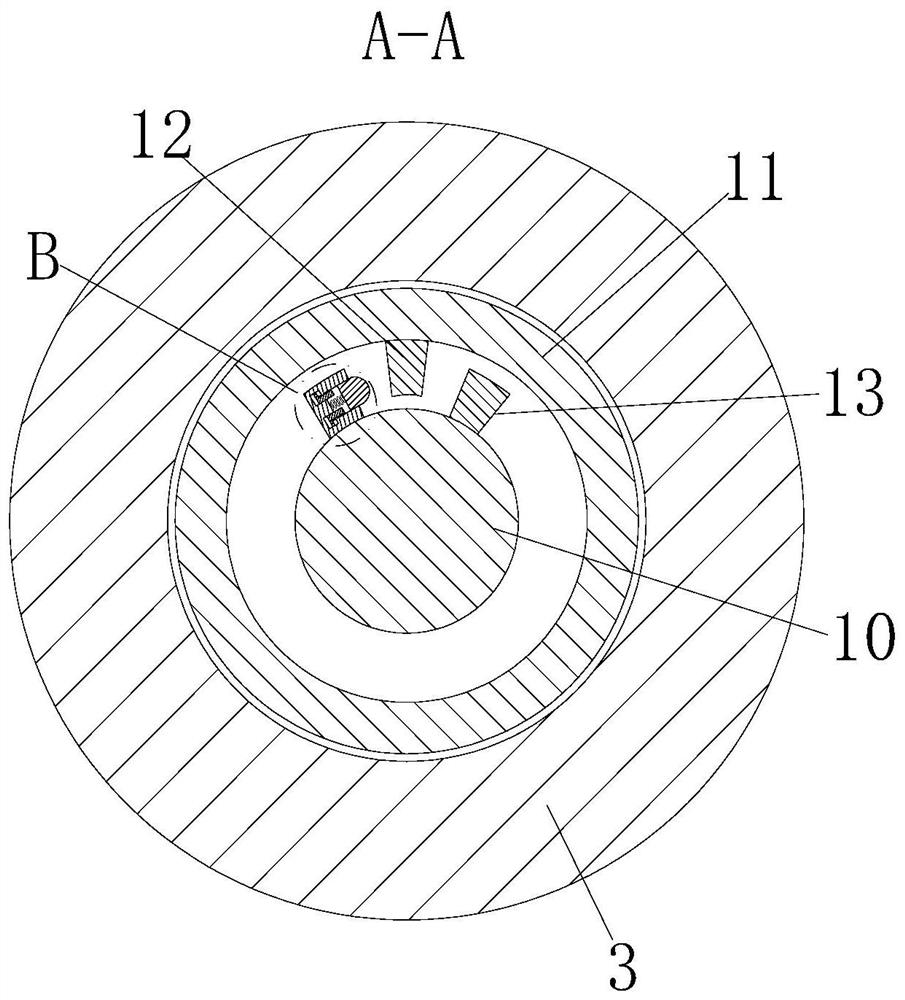

[0032] As an embodiment of the present invention, the notch direction of the adjustment groove and the corresponding second tooth block 9 are designed vertically; the adjustment blocks 17 are all slid perpendicular to the direction corresponding to the second tooth block 9; the A third spring is firmly connected between the adjustment block 17 and the groove bottom of the corresponding adjustment groove; during operation, the adjustment block 17 is axially slid by making the movement direction of the adjustment block 17 perpendicular to the corresponding second tooth block 9 , to avoid the direct radial sliding design, the adjustment block 17 is susceptible to centrifugal force, even if the operation of the working machine 6 is blocked, the centrifugal force of the adjustment block 17 will prevent the adjustment block 17 from retracting, affecting the response of the adjustment block 17, This reduces the response sensitivity of the device.

[0033] As an embodiment of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com