Six-phase seven-bridge-arm series winding circuit topology with reverse winding and modulation method of six-phase seven-bridge-arm series winding circuit topology

A technology of reverse winding and series winding, applied in the shape/style/structure of winding conductors, motor generator control, control of electromechanical brakes, etc., can solve high device cost, low utilization rate of DC voltage, increase in the number of bridge arms, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0067] Taking the six-phase seven-arm motor drive system as an example, experiments are carried out according to the specific implementation steps of the present invention. And take the data obtained in the experimental process of the present invention as an example, to describe and verify the present invention in detail. The simulation parameter settings are shown in Table 1:

[0068] Table 1

[0069] parameter value Phase 6 bus voltage 400V voltage modulation ratio 1 output voltage frequency 800Hz Magnetizing inductance 3.4mH Stator resistance 1.5Ω

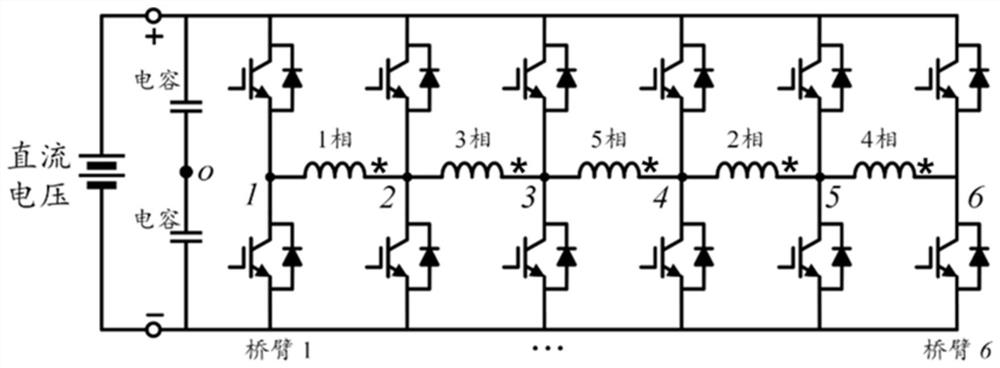

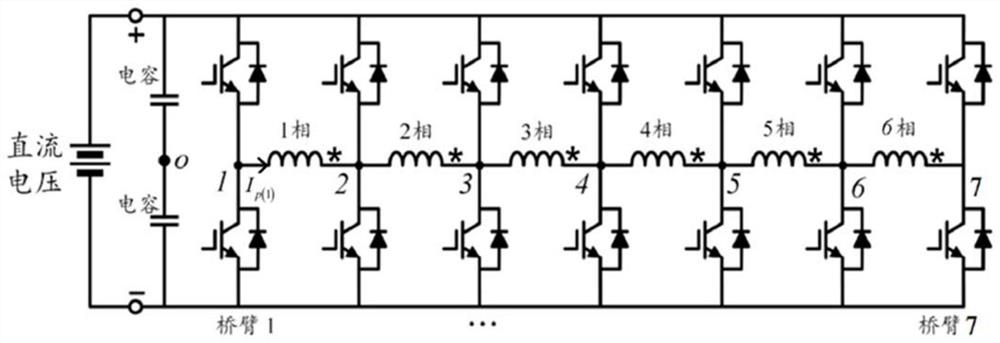

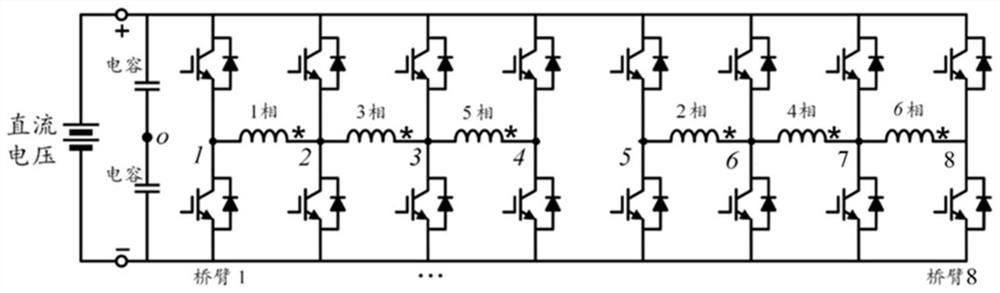

[0070] According to the present invention, four kinds of six-phase motor winding series connection modes with reversed winding are proposed: or The windings are connected in series according to any one of these four connections, leading to 7 nodes. Connect the 7 motor winding nodes drawn out with the 7 bridge arm output nodes sequentially to obtain the circuit topology...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com