Skeleton polishing former

A shaper and bone technology, applied in the field of knee joint surgery, can solve the problems of prolonging grinding time, affecting the operation process, reducing grinding efficiency, etc., and achieving the effect of saving grinding time, convenient and fast operation, and reducing direct contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

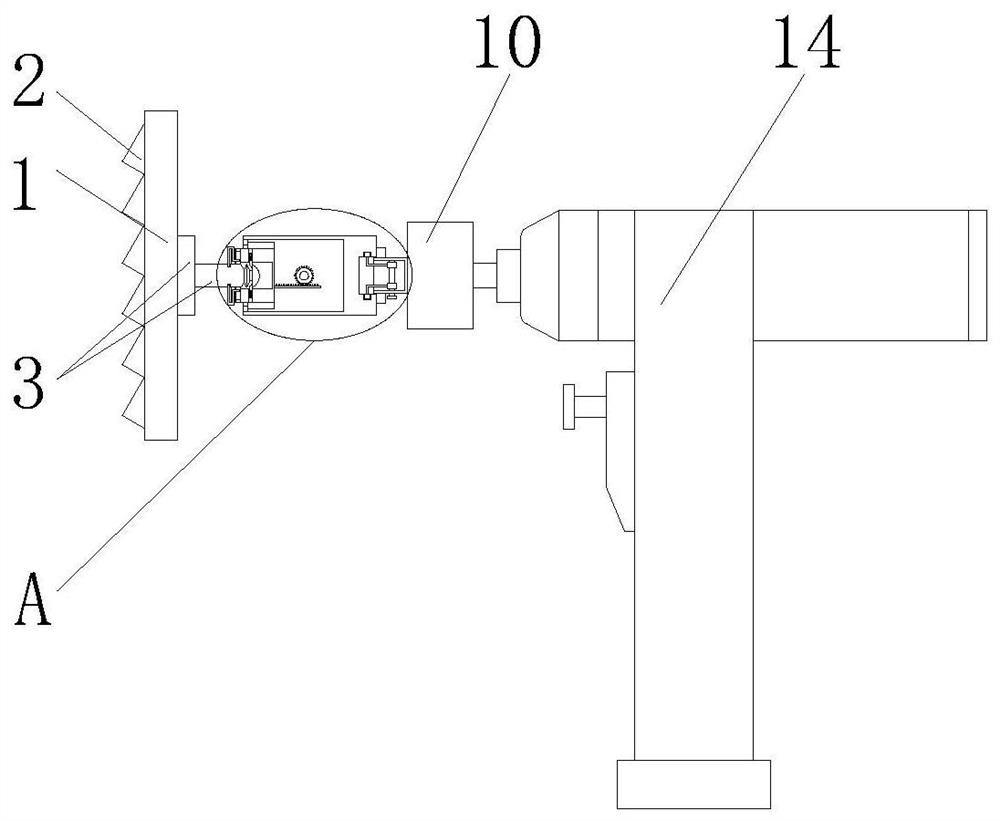

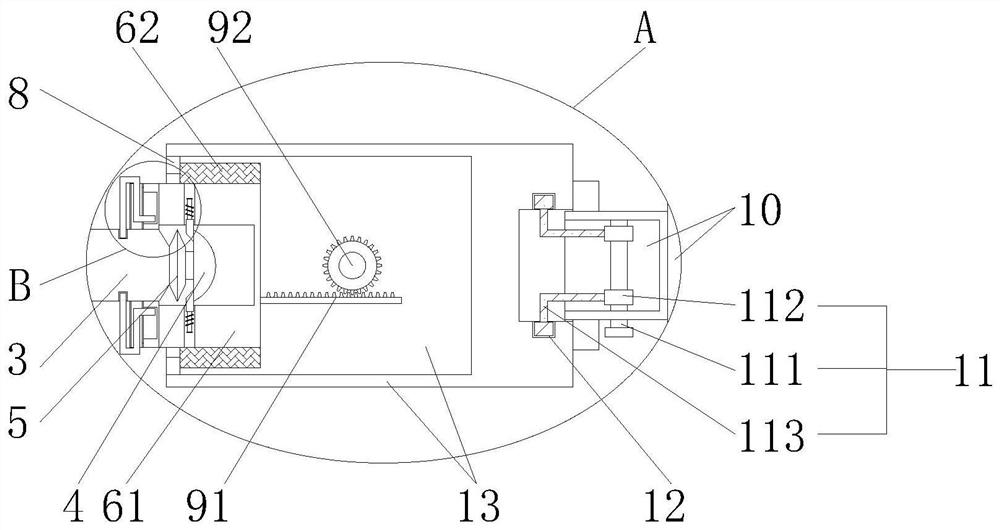

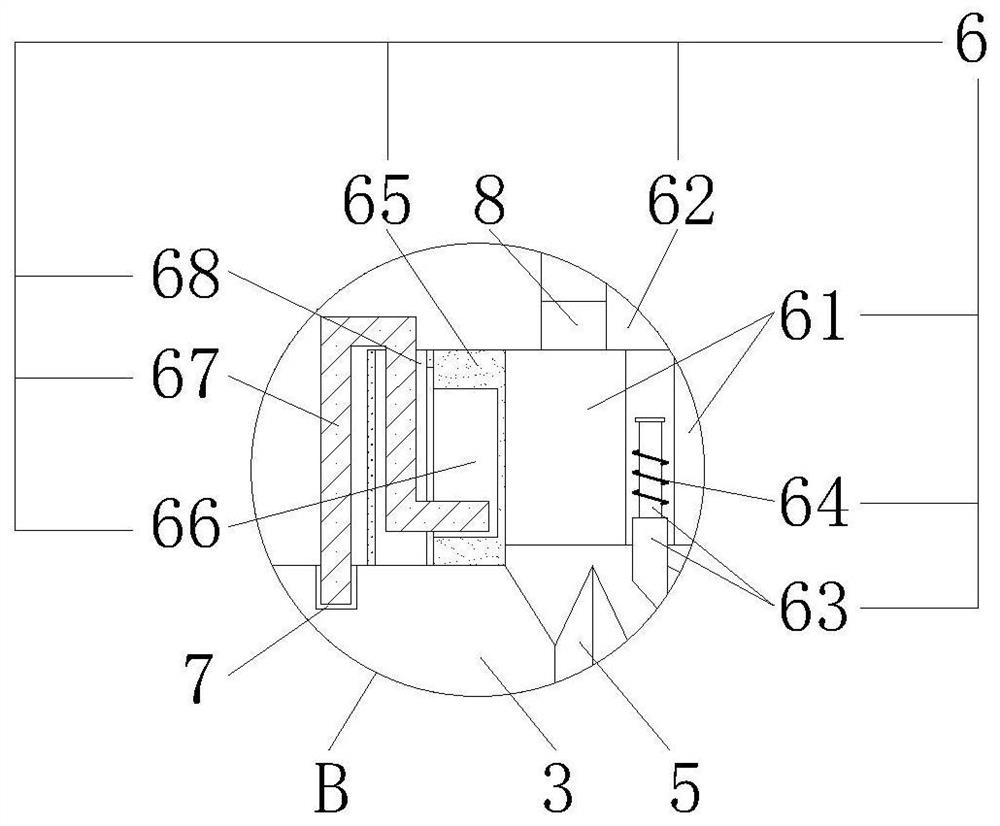

[0030] See Figure 1-8 The present invention provides a technical solution: a skeletal strobe profile comprising a tibial forming instrument body 1 and a drill 14, a side of the tibial formator body 1 is distributed with zigzag 2, and the other side of the tibial formator main body 1 is fixed Block 3, and the other end of the fixing block 3 fixes a block 4, the outer surface sleeve of the block 4 is connected to the slider 5, and the clip 4 is connected to the limit mechanism 6, and the limit mechanism 6 is located at the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com