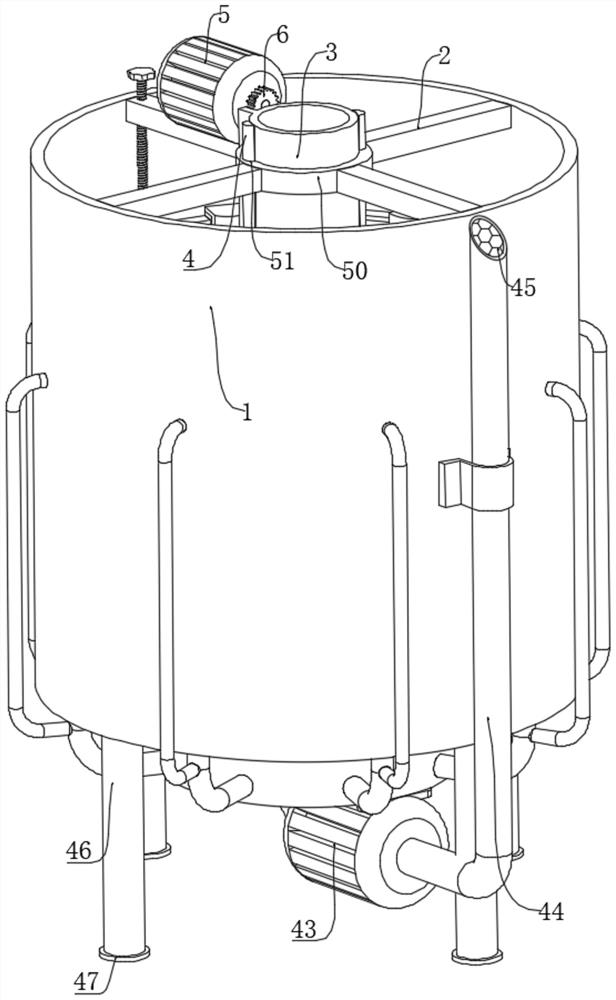

A petrochemical oil-water separation device

An oil-water separation device and petrochemical technology, applied in the petroleum industry, separation methods, filtration and separation, etc., can solve the problems of reducing the oil-water separation effect, the deterioration of the oil-water separation effect of the produced fluid, and the deterioration of the oil-water separation effect. The area of floating separation is comprehensive, reducing the range of oil droplets and improving the effect of passing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

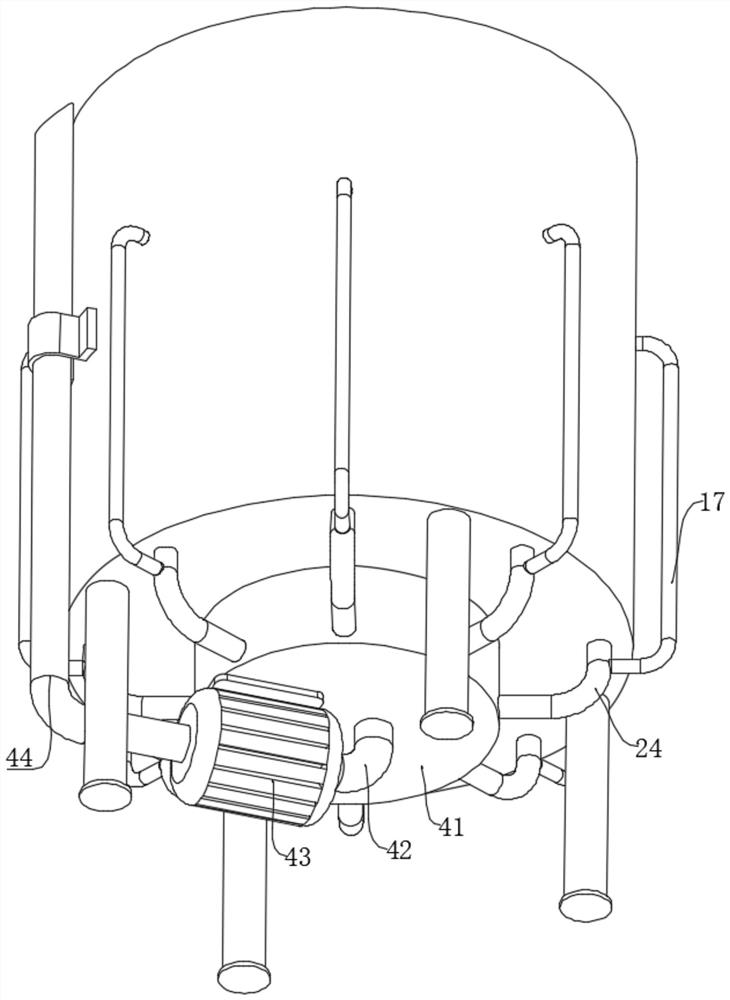

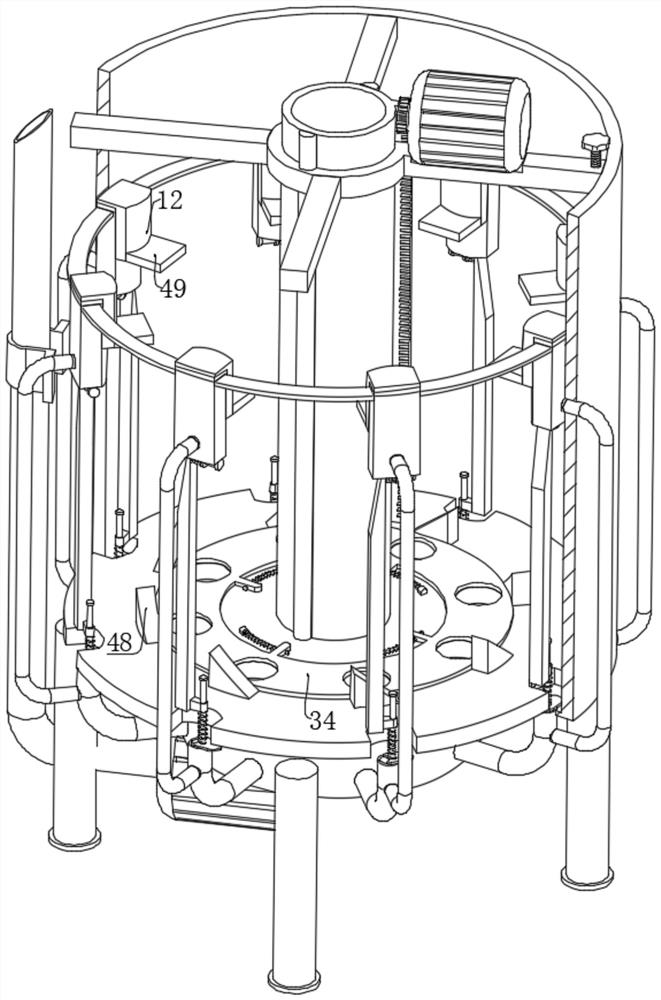

[0033] As an embodiment of the present invention, a single air intake mechanism includes a plurality of movable rods 23, and the movable rods 23 are located under each connection housing 11 respectively. One side of the top of the movable rod 23 is a tangential structure, and the top of the movable rod 23 The other side is fixedly connected with the second circular rod 20, one end of the second circular rod 20 is fixedly connected with the second baffle plate 21, the bottom of the connection shell 11 is fixedly connected with the first connecting ring 19, the second The circular rods 20 are all sleeved in the adjacent first connecting rings 19 , the second circular rods 20 between the first connecting ring 19 and the movable rod 23 are all sleeved with second springs 22 , and the lower part of the movable rod 23 One side of each of the adjacent arc-shaped grooves 31 is in contact with the adjacent arc groove 31, the other side below the movable rod 23 is fixedly connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com