Energy-saving and efficient coating drying device capable of achieving uniform drying

A drying device and high-efficiency technology, which is applied to devices for applying liquid to surfaces, coatings, pre-treatment surfaces, etc. The effect of expanding the range, convenient use, and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions in the embodiments of the present invention will be apparent from the drawings in the embodiment of the present invention.

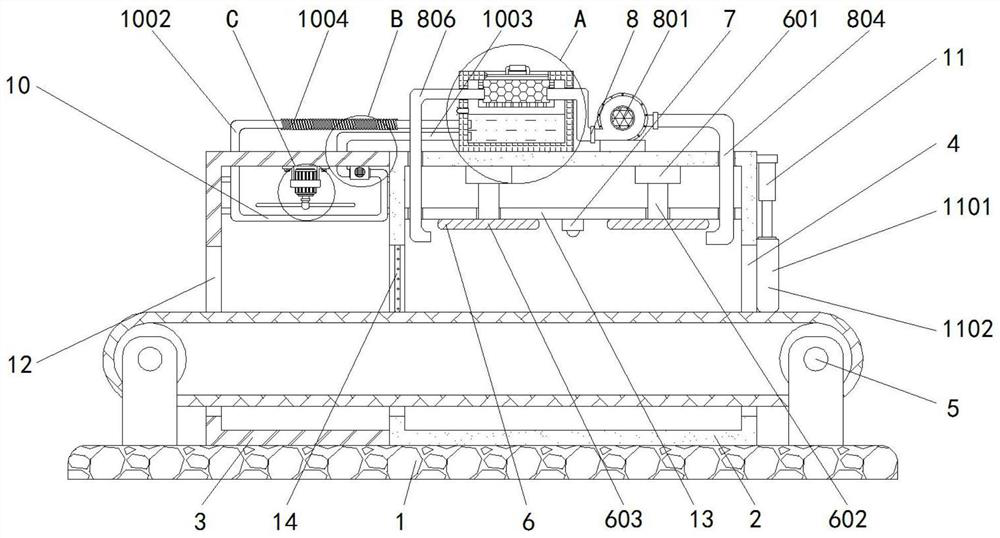

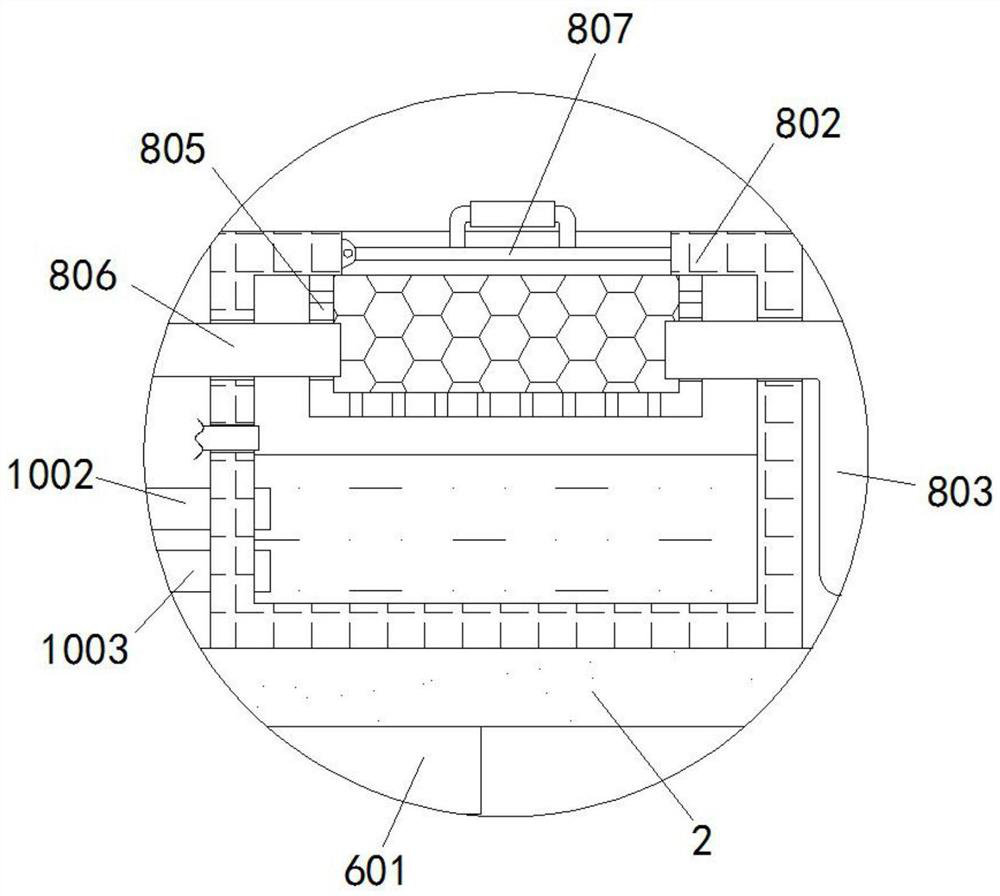

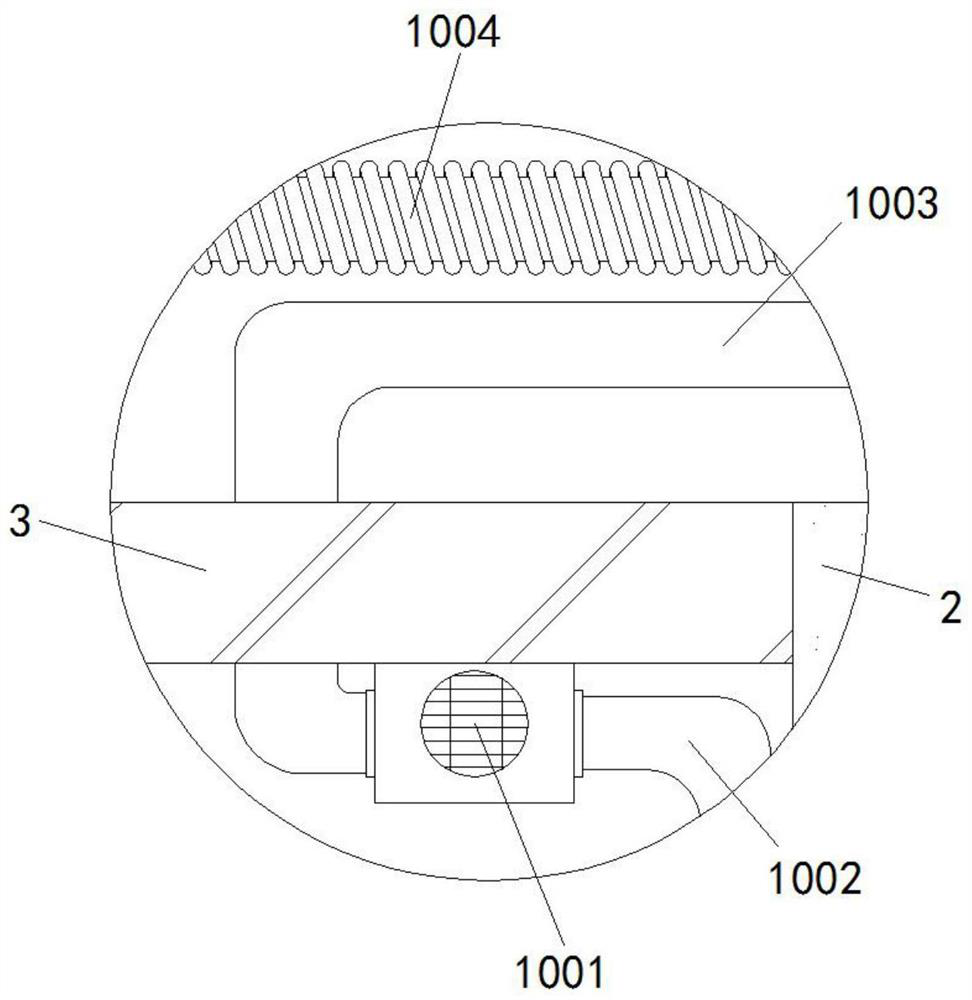

[0025] See Figure 1-5, A uniformly dried energy-saving high-efficiency coating drying device, including the base 1, the top of the base 1 fixedly mounted having a dry boon 2, and the left side of the drying boon 2 is fixedly mounted with a cooling boon fixed to the base 1. 3. Open a perforation 4 in the left and right sides of the drying bin 2, and extend to the inside of the dry booside 2, and one end is opened and extended to the inside of the cooling boon 3 on the left side of the cooling bond 3. The top of the base 1 is fixedly mounted having a transmission device 5 through the perforation 4 and the discharge hole 12 and extends to the left side of the cooling boon 3, and the inside of the drying bin 2 is fixedly mounted on the cross plate 13, the dry bin of the perforation 4. 2 The inner top wall fixation has a number of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com