A kind of viscosity-reducing polycarboxylate water reducer and preparation method thereof

A viscous polycarboxylate and superplasticizer technology, applied in the field of superplasticizers, can solve problems such as slow flow speed and high viscosity of fresh concrete, and achieve the effects of reducing viscosity, reducing internal friction, and reducing internal friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

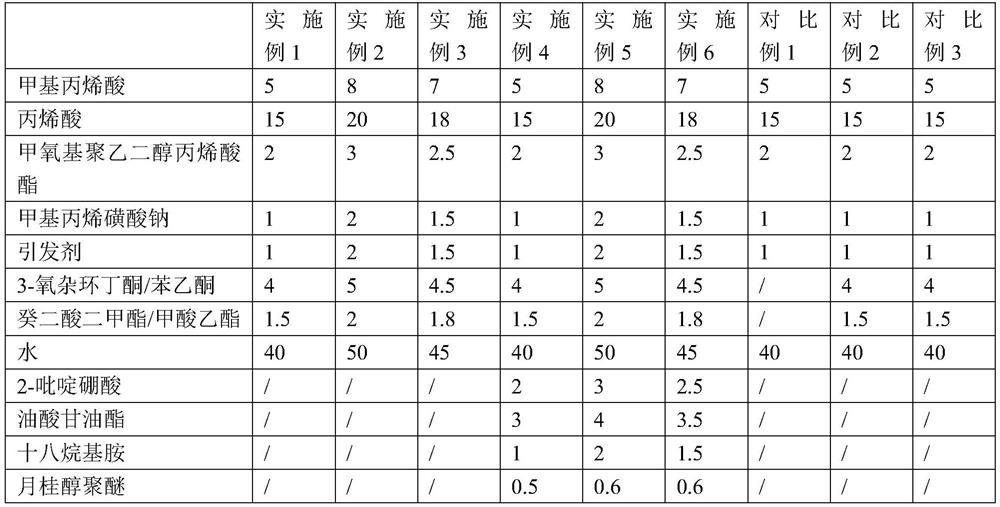

[0040] This application discloses a viscosity-reducing polycarboxylate water reducer, the raw materials of which include methacrylic acid, acrylic acid, methoxypolyethylene glycol acrylate, sodium methacrylate, initiator, 3-oxetane Ketone, dimethyl sebacate and water, wherein the initiator is ammonium persulfate, and the contents of each component are shown in Table 1 below.

[0041] A preparation method of a viscosity-reducing polycarboxylate water reducer, comprising the steps of:

[0042] Mix 3-oxetanone and dimethyl sebacate, heat up to 40°C and stir for 30 minutes to obtain a heterocyclic product;

[0043] Under the condition of constant temperature water bath at 90°C, mix methacrylic acid, acrylic acid, methoxypolyethylene glycol acrylate and sodium methacrylic sulfonate to obtain a mixed solution, then add it dropwise to water, and then add the initiator dropwise, in 3h After the internal dropwise addition, continue to keep warm for 1 hour, adjust the pH value to 5 wit...

Embodiment 2

[0045] This application discloses a viscosity-reducing polycarboxylate water reducer, the raw materials of which include methacrylic acid, acrylic acid, methoxypolyethylene glycol acrylate, sodium methacrylate, initiator, 3-oxetane Ketone, dimethyl sebacate and water, wherein the initiator is potassium persulfate, and the contents of each component are shown in Table 1 below.

[0046] A preparation method of a viscosity-reducing polycarboxylate water reducer, comprising the steps of:

[0047] Mix 3-oxetanone and dimethyl sebacate, heat up to 45°C and stir for 40 minutes to obtain a heterocyclic product;

[0048] Under the condition of constant temperature water bath at 95°C, mix methacrylic acid, acrylic acid, methoxypolyethylene glycol acrylate and sodium methacrylic sulfonate to obtain a mixed solution, then add it dropwise to water, and then add the initiator dropwise, in 4h After the internal dropwise addition, continue to keep warm for 1 hour, adjust the pH value to 6 wi...

Embodiment 3

[0050]This application discloses a viscosity-reducing polycarboxylate water reducer, the raw materials of which include methacrylic acid, acrylic acid, methoxypolyethylene glycol acrylate, sodium methacrylate, initiator, 3-oxetane Ketone, dimethyl sebacate and water, wherein the initiator is ammonium persulfate, and the contents of each component are shown in Table 1 below.

[0051] A preparation method of a viscosity-reducing polycarboxylate water reducer, comprising the steps of:

[0052] Mix 3-oxetanone and dimethyl sebacate, heat up to 43°C and stir for 35 minutes to obtain a heterocyclic product;

[0053] Under the condition of a constant temperature water bath at 92°C, mix methacrylic acid, acrylic acid, methoxypolyethylene glycol acrylate and sodium methacrylic sulfonate to obtain a mixed solution, then add it dropwise to water, and then add the initiator dropwise, within 3 hours After the internal dropwise addition, continue to keep warm for 1 hour, and adjust the pH ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com