Waste catalytic fermentation equipment for livestock breeding

A technology for fermentation equipment and waste materials, which is applied in the field of catalytic fermentation equipment for waste materials used in animal husbandry, can solve the problems of multi-operation time and manual coordination, increase labor waste and fermentation operation time, etc., to improve fermentation processing efficiency, improve catalytic mixing efficiency, reduce The effect of duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

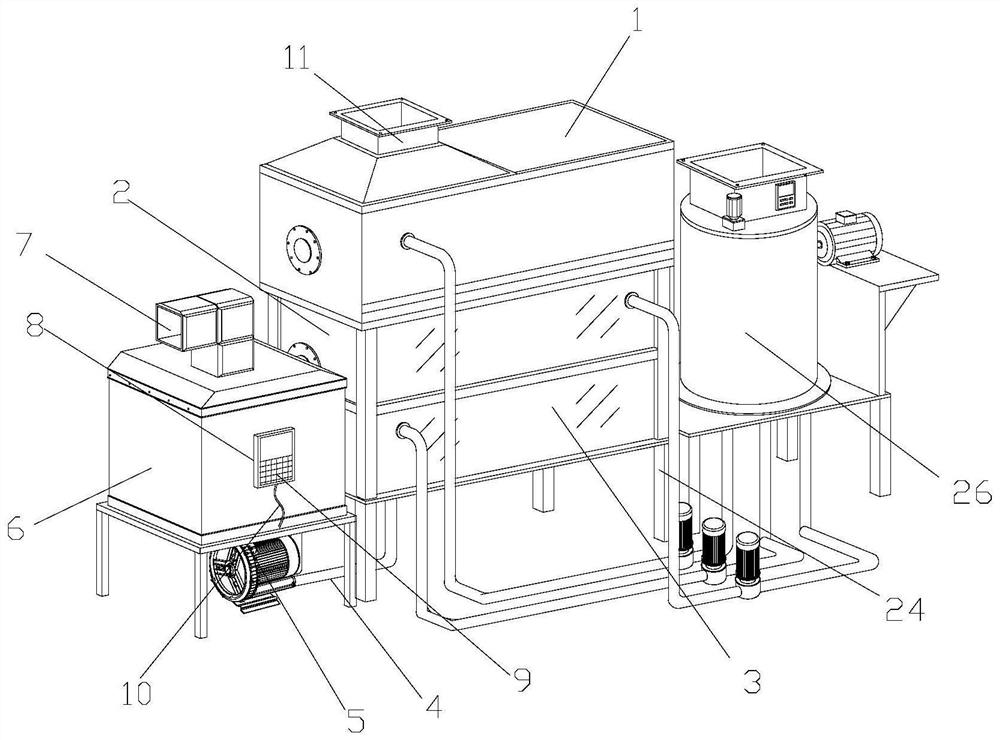

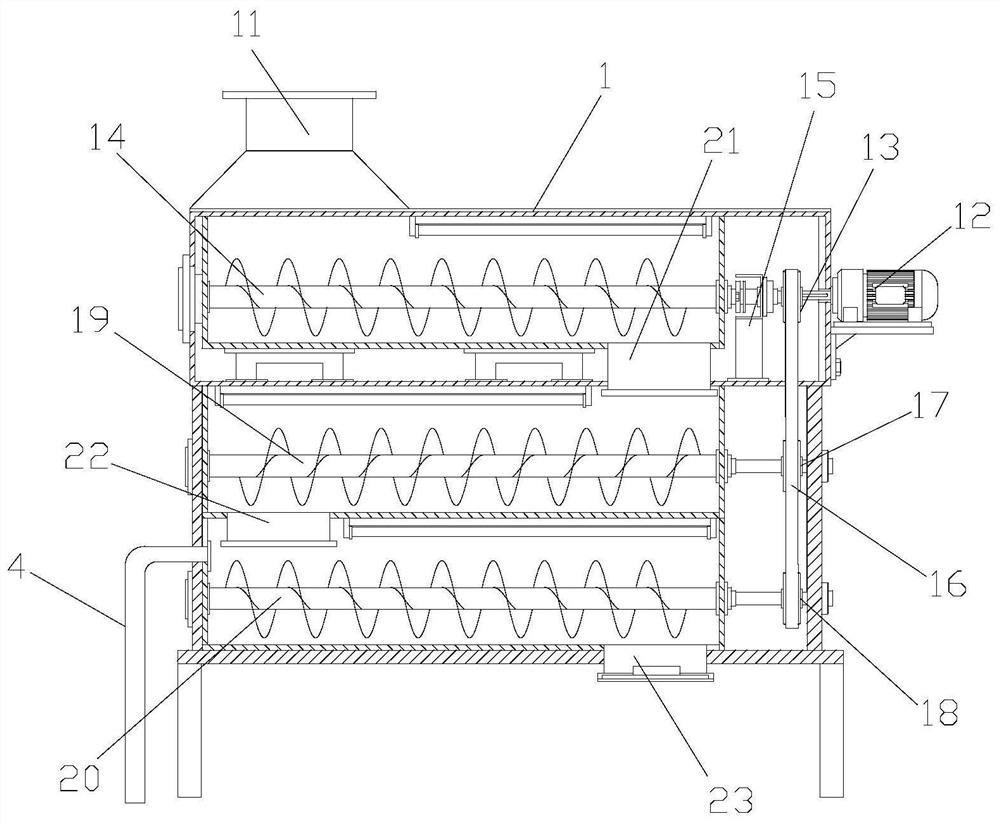

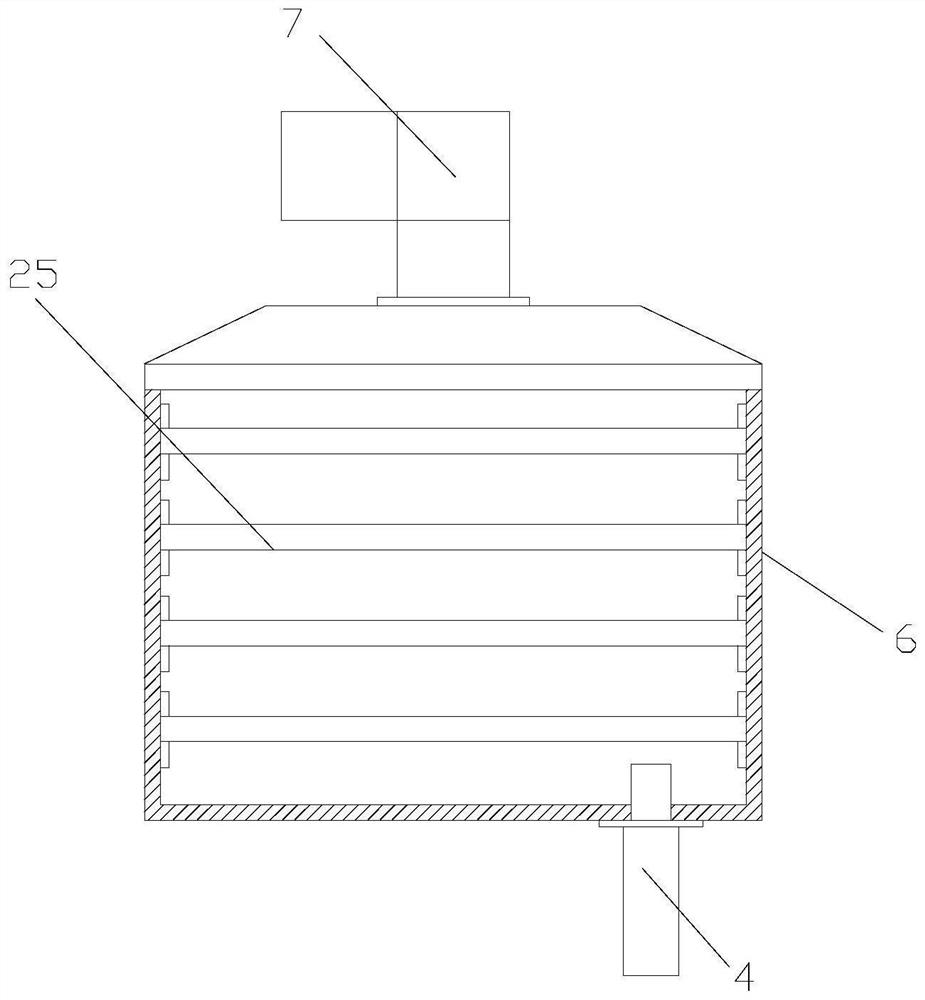

[0032] see Figure 1-9 , the present invention provides a catalytic fermentation equipment for animal husbandry waste through improvement, including a top bin 1, a receiving bin 2, a bottom bin 3, an air pipe 4, a first fan 5, an air filter bin 6, an exhaust pipe 7, Control panel 8, control key 9, power cord 10, material inlet 11, first motor 12, driving wheel 13, first auger 14, support 15, shaft belt 16, first driven wheel 17, second driven wheel 18. The second auger 19, the third auger 20, the first guide port 21, the second guide port 22, the third guide port 23, the bracket 24, the filter plate 25, the batching mechanism 26 and the electric heating component 27, the top chamber 1 The bottom end is sequentially welded to install the receiving bin 2 and the bottom bin 3, the right end of the ventilation pipe 4 is installed on the bottom bin 3, and the first fan 5 at the left end of the ventilation pipe 4 is connected to the air filter bin 6 and fixed, and the top of the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com