Vibration and noise reduction device and operation method thereof

A vibration reduction and noise reduction technology, applied in heating methods, noise suppression, household heating, etc., can solve the problems of large operating noise of refrigeration parts, fatigue fracture of pipelines, strong vibration, etc., so as to prevent fatigue fracture and prolong Working life, effect of reducing vibration amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

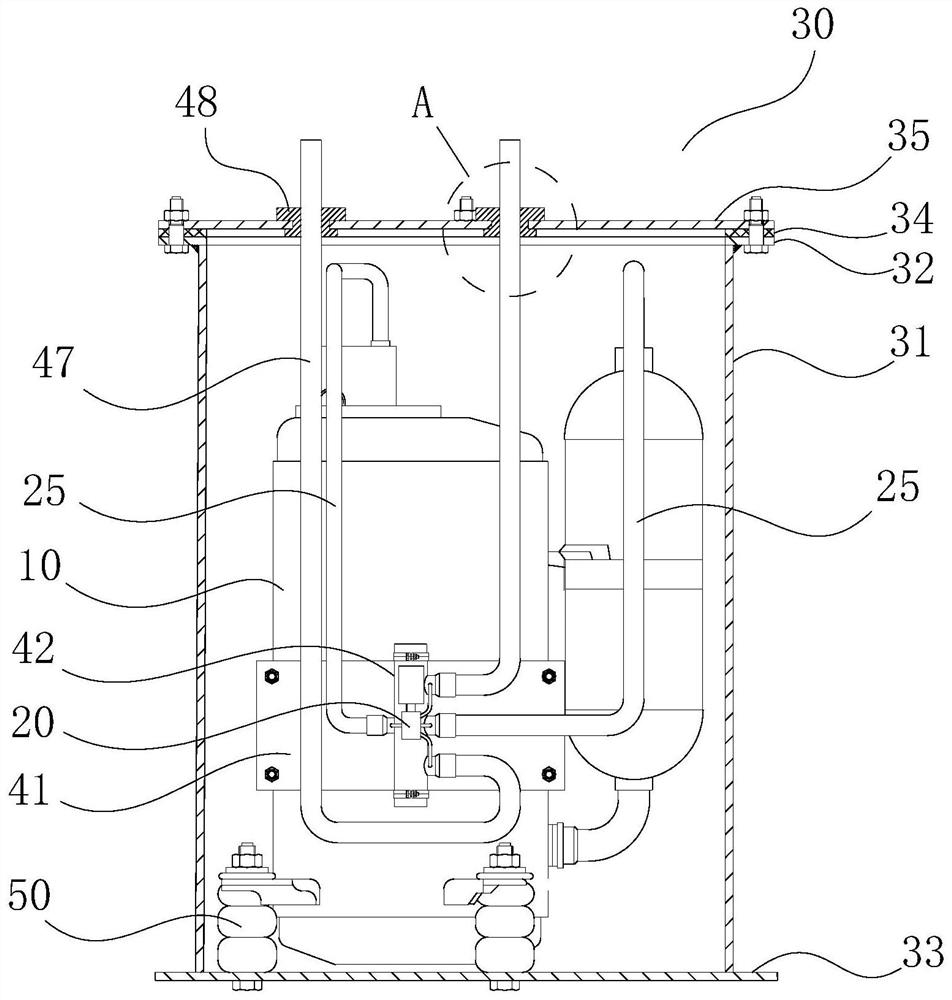

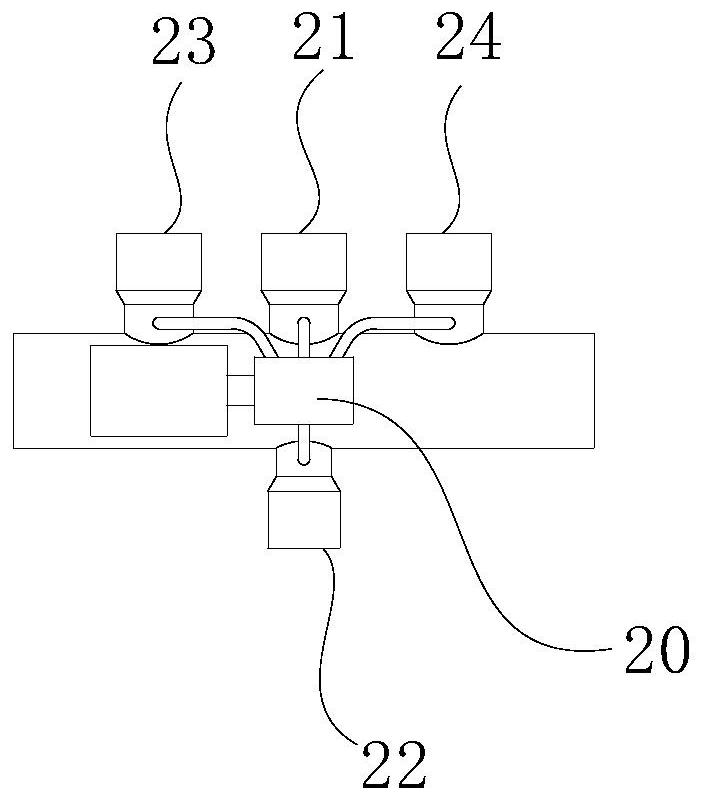

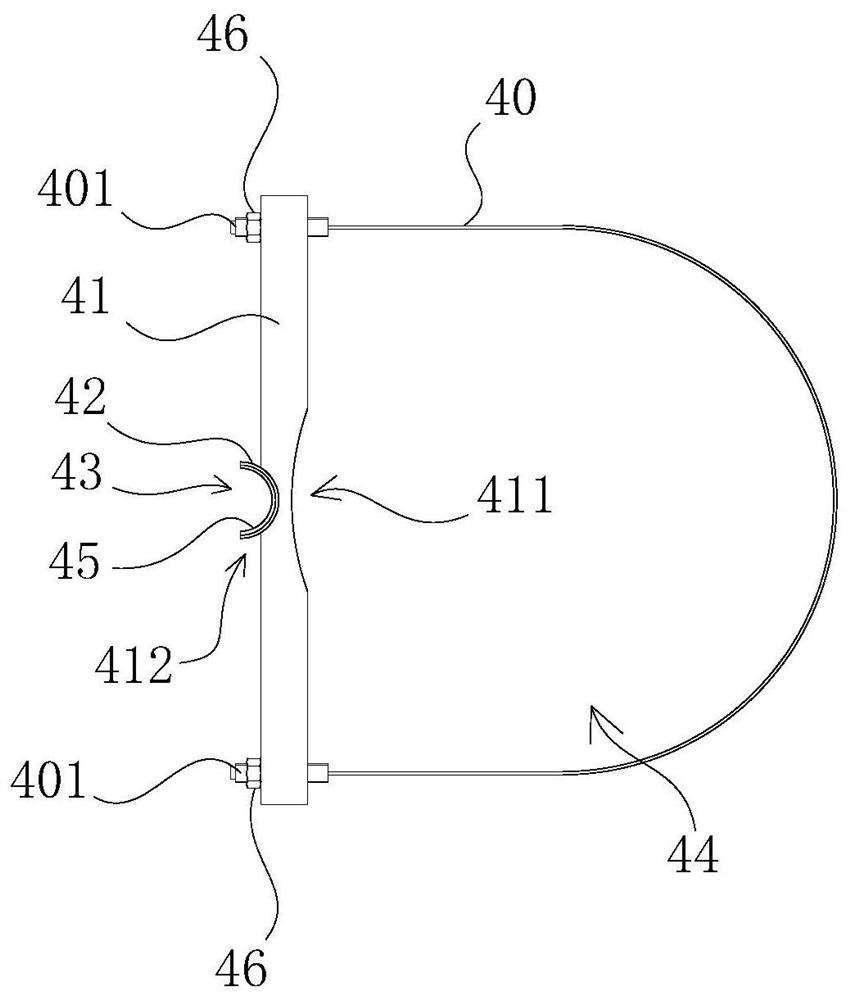

[0037] Such as Figure 1 to Figure 4As shown, the vibration and noise reduction device includes a compressor main body 10, a four-way valve 20, a fastening mechanism and a vibration isolation and noise reduction cylinder 30. The four-way valve 20 has an exhaust port 21 and a return air port 22. Both the exhaust port 21 and the air return port 22 are connected to the compressor main body 10 through the pipeline 25, the compressor main body 10, the four-way valve 20 and the fastening mechanism are all located in the vibration isolation and noise reduction cylinder 30, and the fastening The mechanism includes an installation assembly for installing the four-way valve 20 and a fastening belt 40, both ends of the fastening belt 40 are connected to the installation assembly, and an adjustable gap is formed between the fastening belt 40 and the installation assembly. The sleeve part 44 , the installation assembly is fixed on the shell of the compressor main body 10 through the fasten...

Embodiment 2

[0054] Such as Figure 5 As shown, the difference from Embodiment 1 is that the two through pipes 47 connected to the heat exchanger on the four-way valve 20 are spirally arranged to form the first shock absorber 61 and the second shock absorber 62 respectively. In this embodiment , the first damping tube 61 and the second damping tube 62 are arranged in a circular spring shape, the first damping tube 61 and the second damping tube 62 are coiled outside the compressor main body 10, the first damping tube 61 and the second shock absorbing pipe 62 are set up and down correspondingly, one end of the first shock absorbing pipe 61 is connected to the first port 23 of the four-way valve 20, and the other end protrudes from the vibration isolation and noise reduction tube 30, the second One end of the vibration damping pipe 62 is connected to the second interface 24 of the four-way valve 20 , and the other end protrudes from the vibration isolation and noise reduction cylinder 30 . ...

Embodiment 3

[0058] Such as Figure 6 As shown, the difference from Embodiment 1 is that the vibration and noise reduction device also includes an expansion valve 70, the expansion valve 70 is arranged in the vibration isolation and noise reduction cylinder 30, and the expansion valve 70 has a third connection with the heat exchanger. The interface and the fourth interface, the third interface and the fourth interface are connected with a connecting pipe 71 , and the connecting pipe 71 protrudes from the vibration isolation and noise reduction cylinder 30 . Since the expansion valve 70 is working, the internal orifice produces fluid whistling sound, and the expansion valve 70 is also arranged in the vibration isolation and noise reduction cylinder 30, which can isolate the noise generated by the expansion valve 70, thereby further improving the performance of the air conditioner refrigeration system. Noise reduction effect.

[0059] This embodiment also provides a method for operating a v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com