Blasting construction method for forming certain angle between drill hole and joint

A construction method and angle-fixed technology, which is applied in blasting and other directions, can solve the problems of prolonging construction hours and inconvenient filling of roadbeds, and achieve the effects of reducing secondary crushing, shortening construction hours, and improving the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

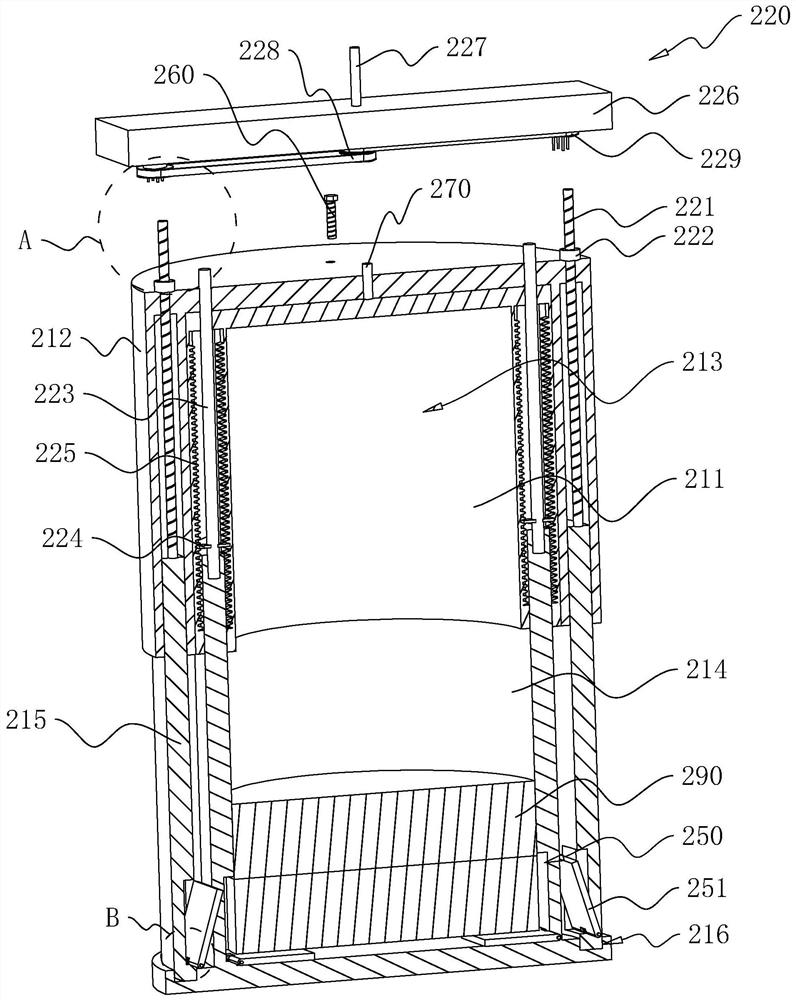

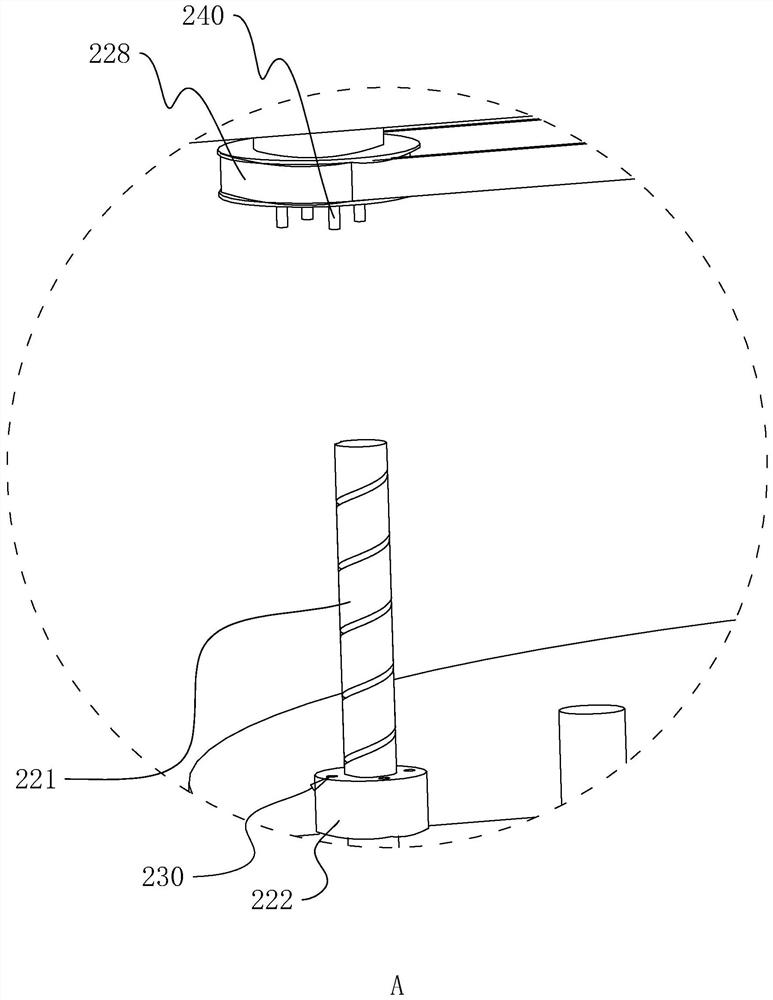

[0049] The following is attached Figure 1-7 The application is described in further detail.

[0050] The embodiment of the present application discloses a blasting construction method in which drilling and joints form a certain angle.

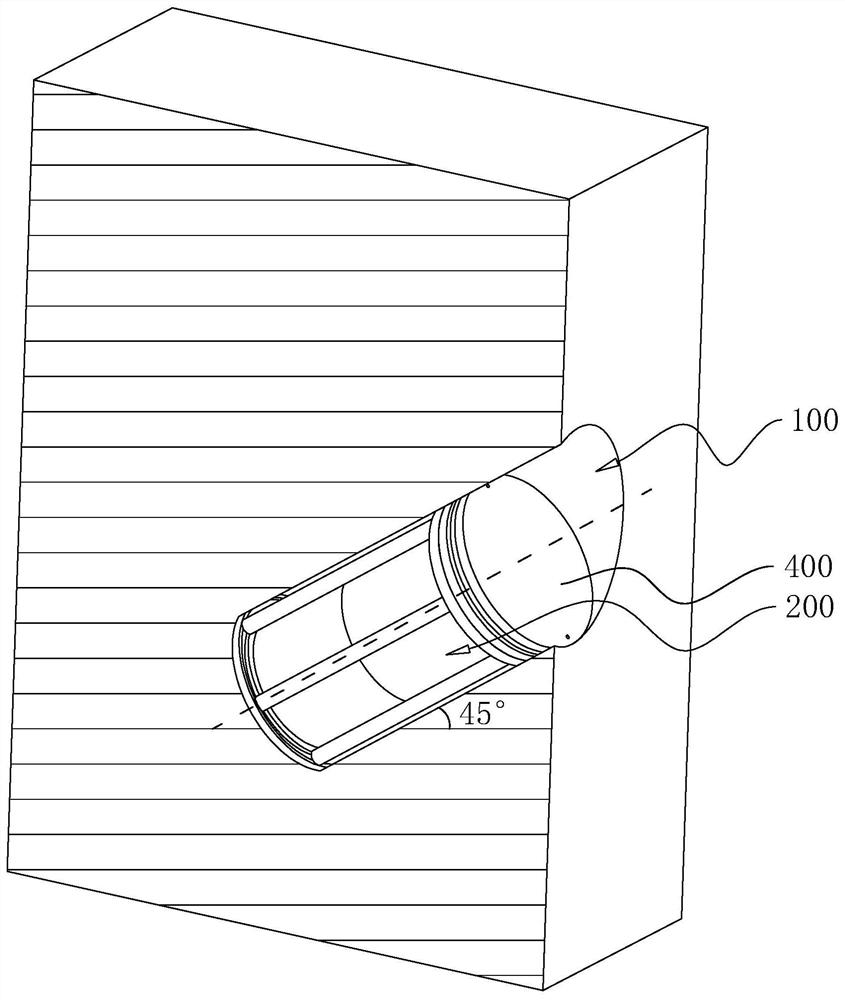

[0051] refer to figure 1 , the blasting construction method in which drilling and joints form a certain angle includes the following steps:

[0052] S1, measuring the direction and inclination of the mountain rock strata; S2, opening holes along the direction and inclination of the mountain rock strata; S3, charging the powder; S4, blocking the borehole 100; S5, detonating.

[0053] In step S1, the geological compass is used to measure the occurrence of the mountain rock formation to be blasted, and then the direction and inclination of the mountain rock formation are judged.

[0054] In step S2, the multi-arm drilling rig is used to drill the hole 100 along the trend and inclination of the rock formation of the mountain, so that the axis o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com