Water tank active absorption type wave maker system and control method

A wave generator and absorption type technology, which is applied in the field of active absorption wave generator system and control of water tank, can solve the limitation of overall system function and wave accuracy, cannot realize active wave making at the same time, and cannot realize synchronous processing of control signals. and other problems, to achieve the effect of improving wave simulation accuracy, improving wave simulation ability, and improving control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

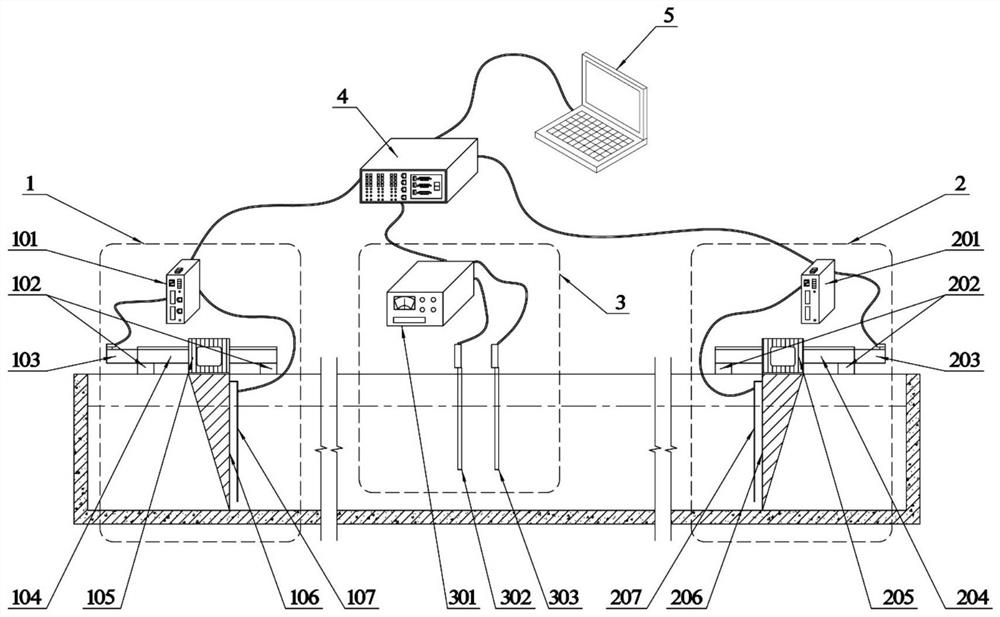

[0028] This embodiment provides a sink active absorption wave maker system, such as figure 1 As shown, the system includes a head end active absorption wave generator 1 , a tail end active absorption wave generator 2 , a reflectivity measuring device 3 , a central servo controller 4 , and a computer 5 .

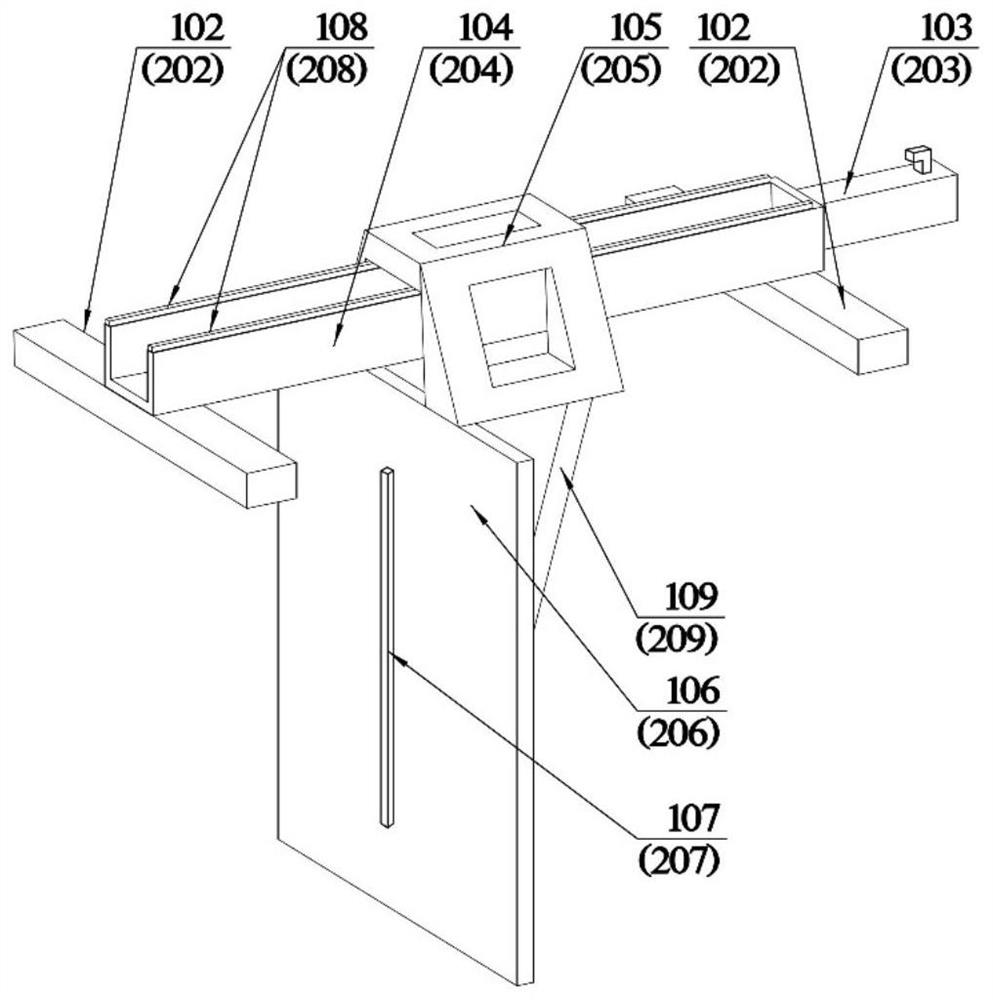

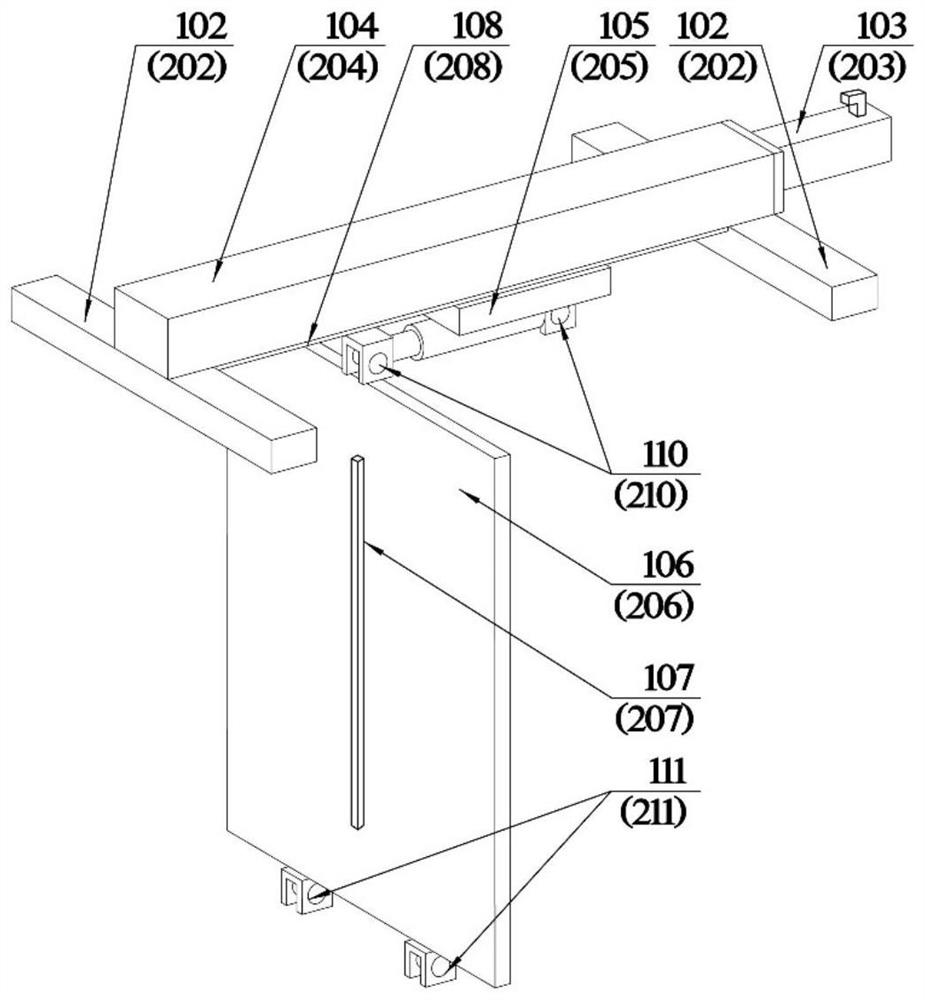

[0029] Specifically, as figure 1 As shown, the head-end active absorption wave maker 1 includes a head-end servo driver 101, a head-end frame 102, a head-end servo motor 103, a head-end unit body 104, a head-end sliding table 105, a head-end wave-making plate 106, The wave height sensor 107 on the head end board; the tail end active absorption wave maker 2 includes a tail end servo driver 201, a tail end rack 202, a tail end servo motor 203, a tail end unit body 204, a tail end slide table 205, a tail end The wave-making plate 206, the wave height sensor 207 on the end plate; the reflectivity measuring device 3 includes a reflectivity measuring wave height collector 301, a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com