High-throughput screening method of strong thixotropic ink

A screening method and thixotropy technology, which is applied in the direction of material inspection products, instruments, and analytical materials, etc., can solve the problems of ink supply interruption and inability to simulate ink high shear conditions, etc., and achieve small sample volume, short test time, convenient and continuous The effect of ink supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

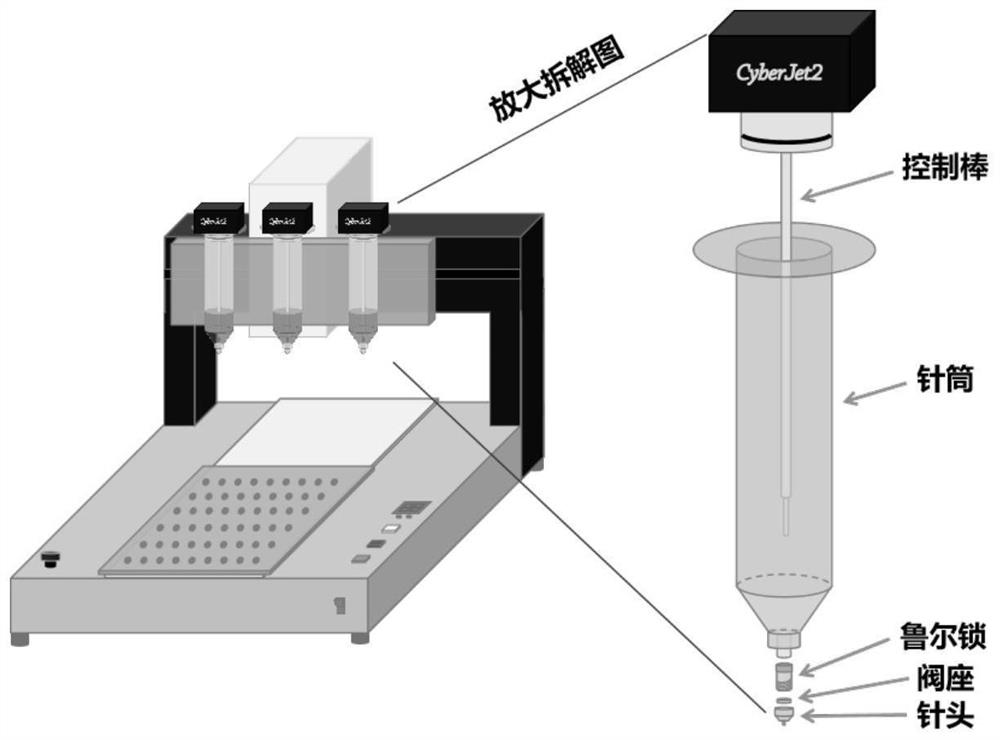

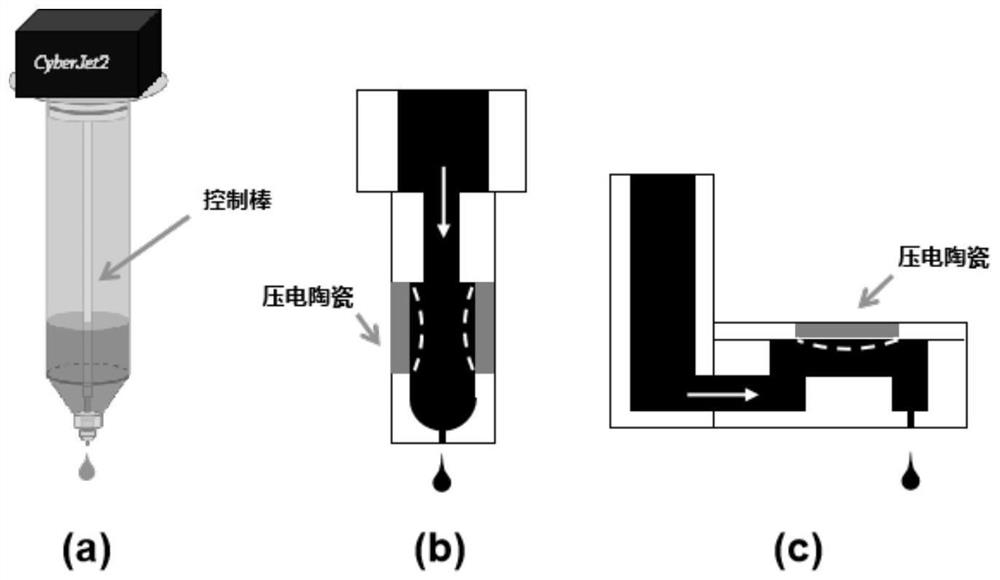

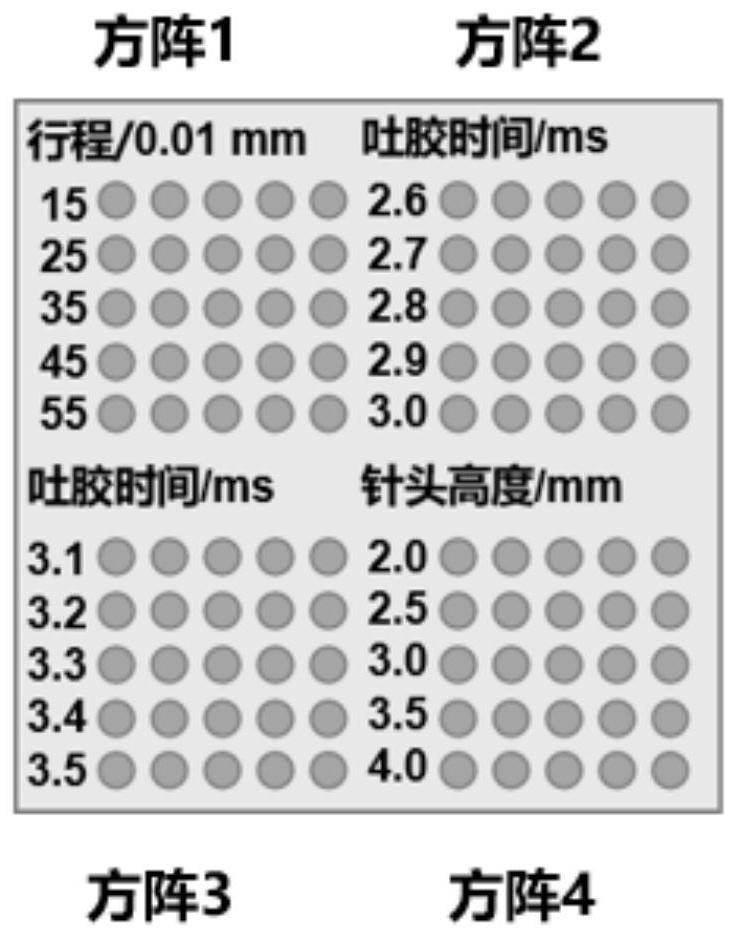

Method used

Image

Examples

Embodiment 1

[0044] A kind of high throughput screening method of Bi strong thixotropic ink (solid content 10vol%), comprises the following steps:

[0045] (1) adjust the composition of strong thixotropic ink, prepare a series of strong thixotropic ink, this series of strong thixotropic ink is made up of Bi powder, BYK-420 and solvent, and solvent adopts the mixture of dehydrated alcohol and ethylene glycol;

[0046] Specifically, the solid content of this series of strong thixotropic inks is 10vol% based on the volume percentage of the single powder Bi powder in the ink, the volume percentage of the additive BYK-420 in the ink is 2.5vol%, and the balance is solvent. The difference in the composition of this series of strong thixotropic inks lies in the different proportions of ethylene glycol in the total volume of the solvent. The specific composition is shown in Table 1. The preparation process of ink is as follows: 1. Weighing powder: take Bi powder (purity 99.9%, 1000 mesh) in glove b...

Embodiment 2

[0060] A kind of high throughput screening method of Bi strong thixotropic ink (solid content 2~20vol%), comprises the following steps:

[0061] (1) adjust the composition of strong thixotropic ink, prepare a series of strong thixotropic ink, this series of strong thixotropic ink is made up of Bi powder, BYK-420 and solvent, and solvent adopts the mixture of dehydrated alcohol and ethylene glycol;

[0062] Specifically, the series of strong thixotropic ink additive BYK-420 accounts for 2.5vol% of the ink, and the balance is Bi powder and solvent. The difference in the composition of this series of strong thixotropic inks is that the volume percentage of the single powder Bi powder in the ink and the proportion of ethylene glycol in the total volume of the solvent are different. The specific composition is shown in Table 2. The preparation process of ink is as follows: 1. Weighing powder: take Bi powder (purity 99.9%, 1000 mesh) in glove box; 2. Prepare solvent: measure absolut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com