Temperature control thread rolling and impurity removing system based on bolt production

A technology of thread rolling and bolting, which is applied in the field of temperature-controlled thread rubbing and impurity removal system, which can solve problems affecting work efficiency, debris splashing, debris melting, etc., and achieve the effect of improving the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

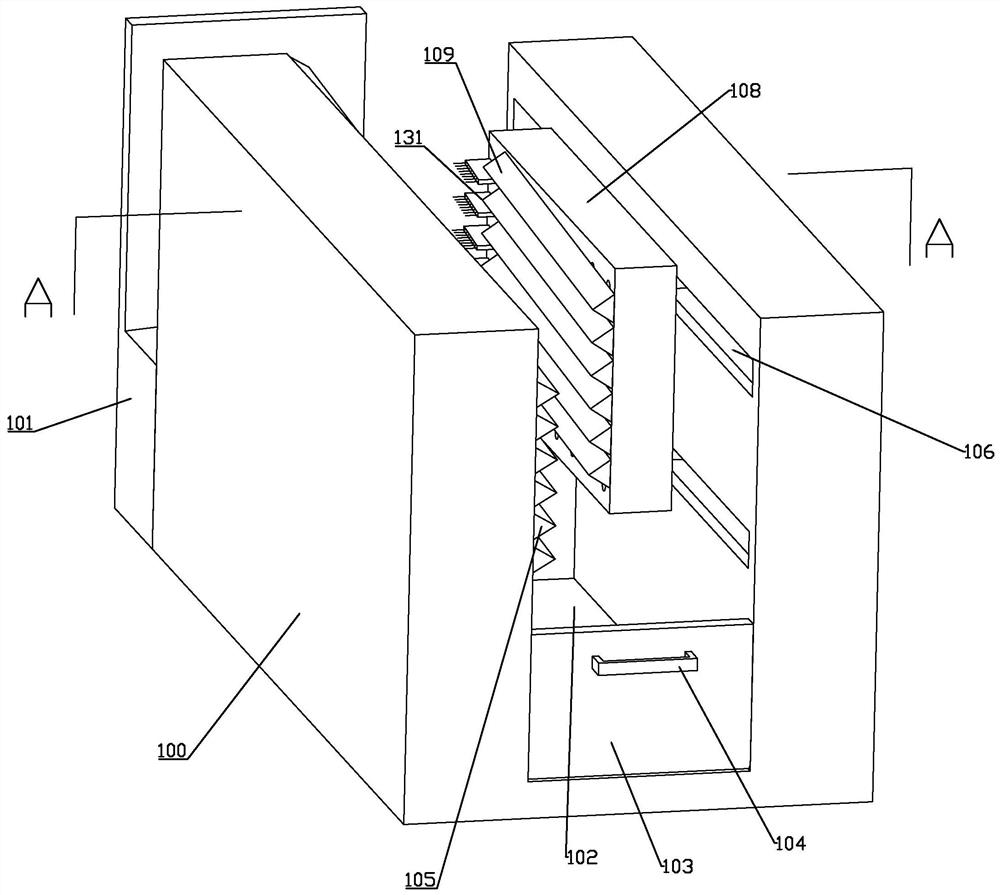

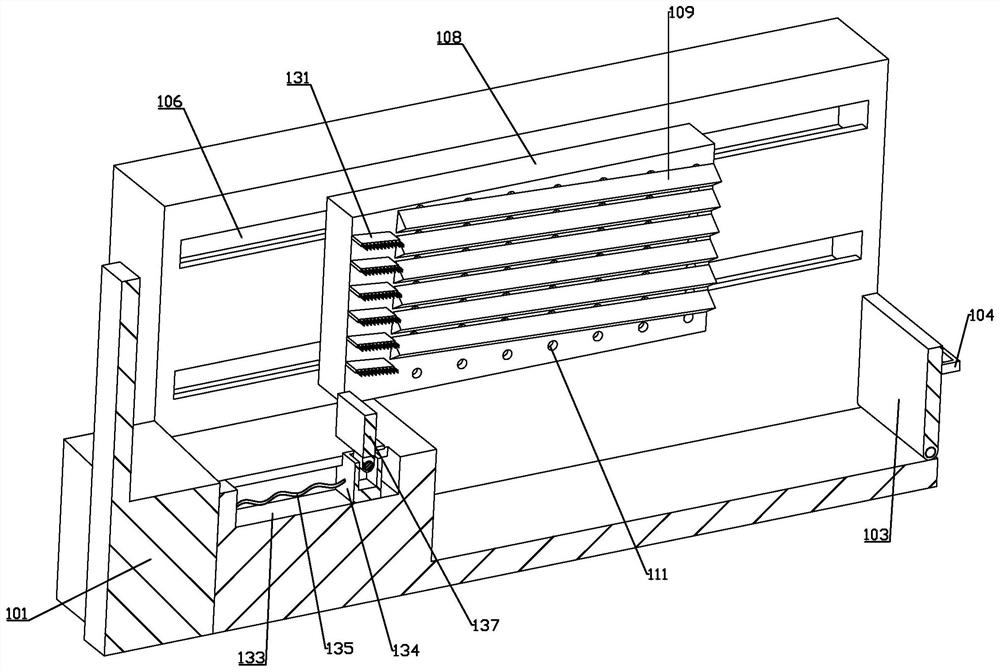

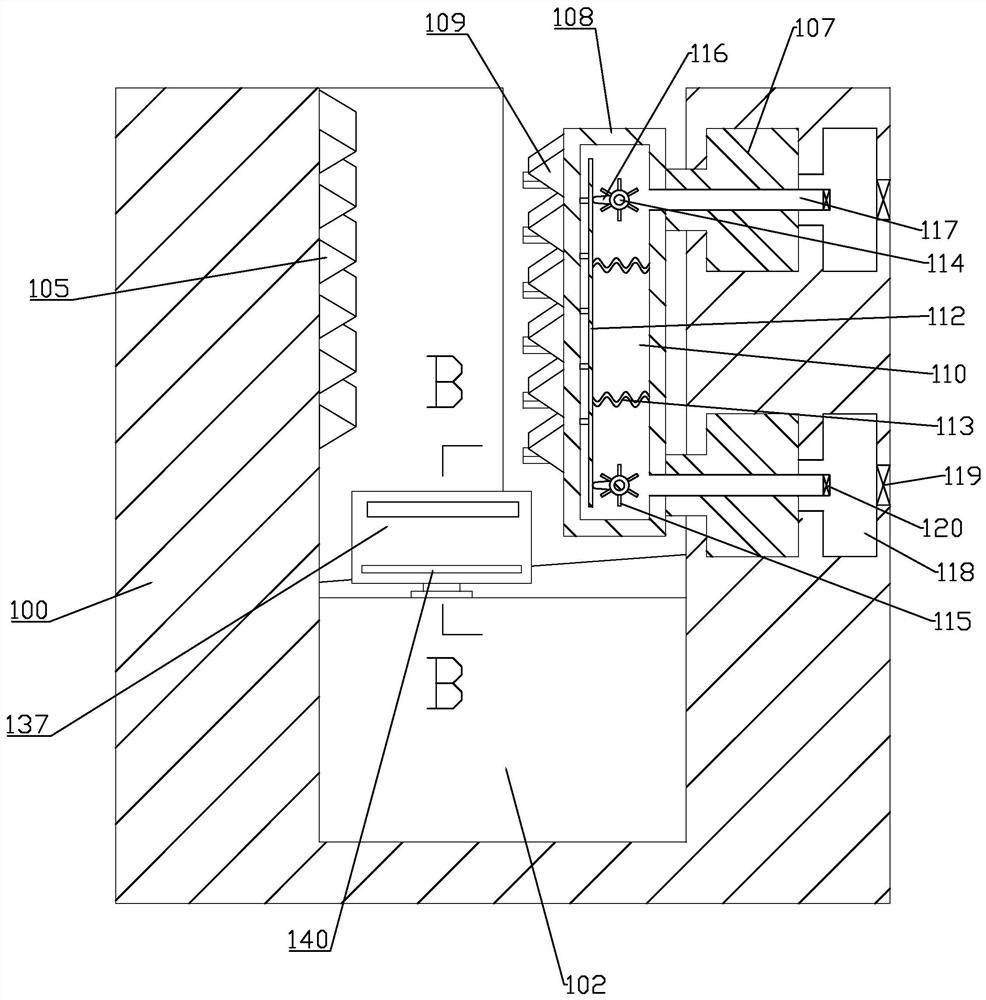

[0027] Such as figure 1 , figure 2 As shown, a system for removing impurities based on temperature control thread rolling for bolt production includes a housing 100, the rear end surface of the housing 100 is fixedly connected with a discharge block 101, and a collecting tank 102 is provided in the housing 100, and the collecting tank 102 The front end surface of the housing 100 is rotated with a material blocking plate 103, the front end surface of the material blocking plate 103 is provided with a handle 104, the left inner wall of the housing 100 is provided with a first thread rolling mechanism, and the right inner wall of the housing 100 is A second thread-rolling mechanism is provided to cooperate with the first thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com