Machining method of high-precision sealing hole

A processing method and technology for sealing holes, which are applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of single rough sealing hole processing method, unable to seal hole size processing, and difficult to meet the needs of use, etc., to prevent The effect of dust and debris affecting the processing environment, improving processing adjustability, and improving processing adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The implementation mode of the present invention is illustrated by specific specific examples below, and those who are familiar with this technology can easily understand other advantages and effects of the present invention from the contents disclosed in this description. Obviously, the described embodiments are a part of the present invention. , but not all examples. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

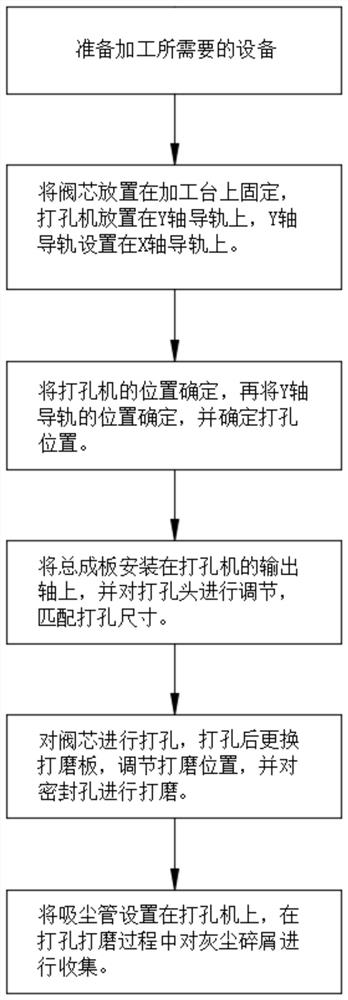

[0025] refer to figure 1 , a processing method for a high-precision sealing hole, the method comprising:

[0026] S1: Place the spool on the processing table, use the fixture to fix the position of the spool, erect the punching machine on the Y-axis guide rail, and lay the Y-axis guide rail on the X-axis guide rail to realize the punching machine. Position adjustment, and set screw knob 1 on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com