Method for improving performance uniformity of 780MPa-grade galvanized dual-phase steel

A dual-phase steel, uniformity technology, applied in the metallurgical field, can solve the problems of downstream customers' use effect, mechanical properties difference, hysteresis, etc., to reduce the local performance fluctuation range, improve the uniformity of mechanical properties, and improve the stability of mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

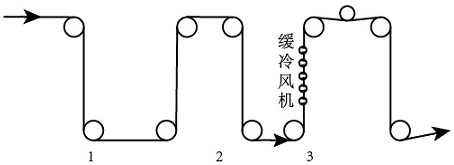

Method used

Image

Examples

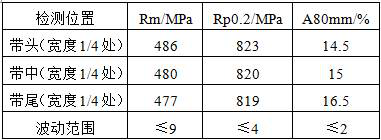

Embodiment 1

[0024] The chemical composition and mass percentage of the 780MPa grade galvanized dual-phase steel in this example are shown in Table 9, and the specifications are: thickness 1.8mm, width 1300mm, and length 1200m.

[0025] The method for improving the performance uniformity of 780MPa grade galvanized dual-phase steel includes the following steps:

[0026] (1) Temperature control of the second heating stage of the continuous annealing furnace: the temperature of the strip steel in the second heating stage is controlled at 765°C, and the residence time of the strip steel in the second heating stage is 1.2min;

[0027] (2) Temperature control of the soaking section of the continuous annealing furnace: the temperature of the strip steel in the soaking section is controlled at 775°C, and the residence time of the strip steel in the soaking section is 1.5min;

[0028] (3) Control the outlet temperature of the slow cooling section of the continuous annealing furnace: the outlet temp...

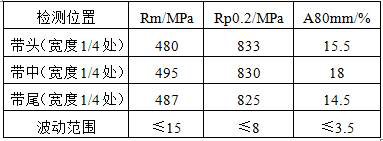

Embodiment 2

[0034] The chemical composition and mass percentage of the 780MPa-grade galvanized dual-phase steel in this example are shown in Table 1. The specifications are: thickness 1.2mm, width 1200mm, and length 1050m.

[0035] The method for improving the performance uniformity of 780MPa grade galvanized dual-phase steel includes the following steps:

[0036] (1) Temperature control of the second heating stage of the continuous annealing furnace: the temperature of the strip steel in the second heating stage is controlled at 775°C, and the residence time of the strip steel in the second heating stage is 1.4min;

[0037] (2) Temperature control of the soaking section of the continuous annealing furnace: the temperature of the strip steel in the soaking section is controlled at 765°C, and the residence time of the strip steel in the soaking section is 1.7min;

[0038] (3) Control the outlet temperature of the slow cooling section of the continuous annealing furnace: the outlet temperat...

Embodiment 3

[0044] The chemical composition and mass percentage of the 780MPa grade galvanized dual-phase steel in this example are shown in Table 1, and the specifications are: thickness 2.0mm, width 1300mm, and length 1050m.

[0045] The method for improving the performance uniformity of 780MPa grade galvanized dual-phase steel includes the following steps:

[0046] (1) Temperature control of the second heating stage of the continuous annealing furnace: the temperature of the strip steel in the second heating stage is controlled at 780°C, and the residence time of the strip steel in the second heating stage is 1.3min;

[0047] (2) Temperature control of the soaking section of the continuous annealing furnace: the temperature of the strip steel in the soaking section is controlled at 780°C, and the residence time of the strip steel in the soaking section is 1.1min;

[0048] (3) Temperature control at the outlet of the slow cooling section of the continuous annealing furnace: the outlet t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com