Fixing support for temperature sensing element for compressor and compressor

A technology of temperature sensing elements and fixing brackets, applied in the field of compressors, can solve the problems of untimely control actions and inability to accurately reflect working conditions, and achieve the effect of accurate temperature sensing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

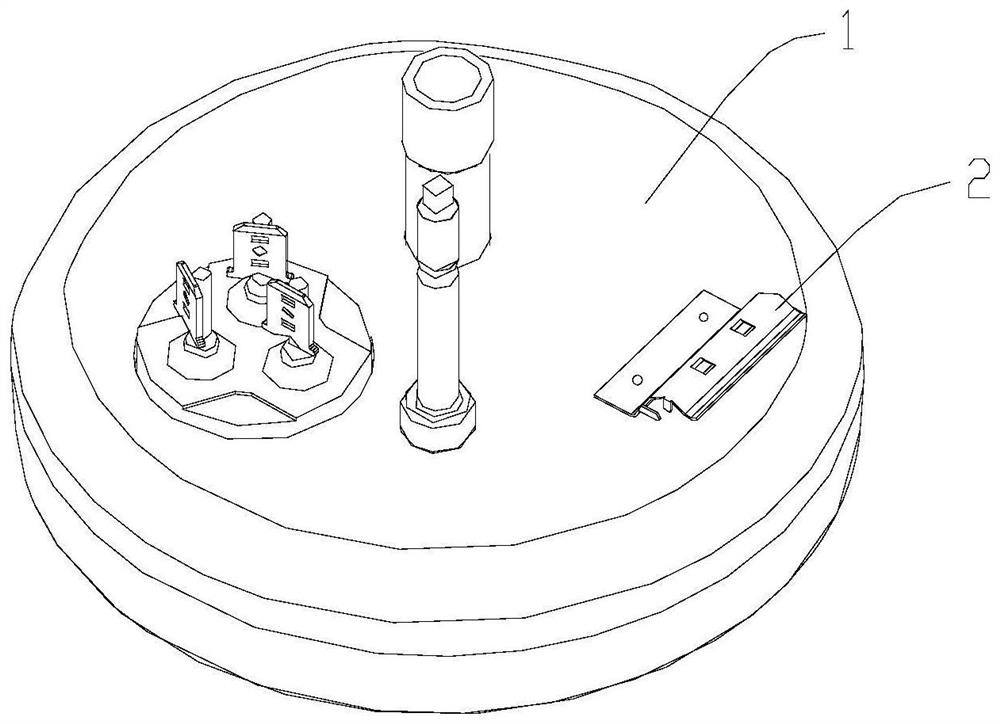

[0038] Such as Figure 1-4 Indicated.

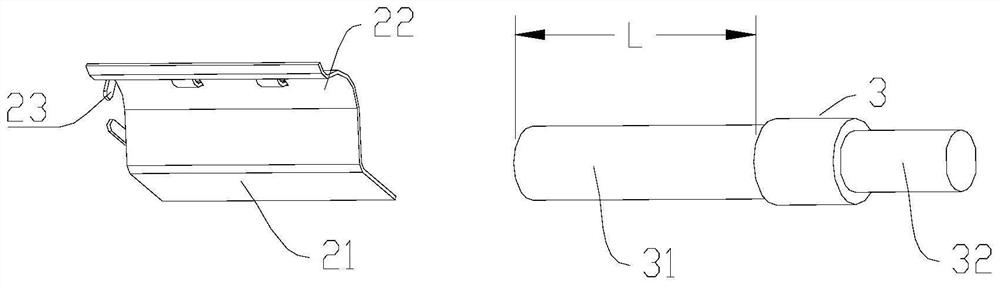

[0039] The fixing bracket 2 includes a mounting portion 21 and an elastic cavity cover 22, and the fixing bracket 2 is mounted on the compressor housing 1 by the mounting portion 21, in the present embodiment, the compressor housing 1 is the upper casing of the compressor.

[0040] The mounting portion 21 has a mounting surface 211, and the mounting portion 21 is connected to the compressor housing 1 through the mounting surface 221. The connection of the mounting portion 21 and the compressor housing 1 can be achieved by welding. Such as image 3 As shown, in the present embodiment, the mounting portion 21 is provided with a solder joint 222 for the mounting portion 21 and the welding connection of the compressor housing 1. In other embodiments, the connection can be achieved directly by welding without providing a solder joint.

[0041] The elastic blocker 22 includes opposing side 221 and side 222, wherein the side portion 221 is connected ...

Embodiment 2

[0050] The compressor thermal temperature of the compressor provided in this example is similar to the embodiment, and only the differences are introduced here. Such as figure 1 , figure 2 , Figure 5 with Figure 6 Indicated.

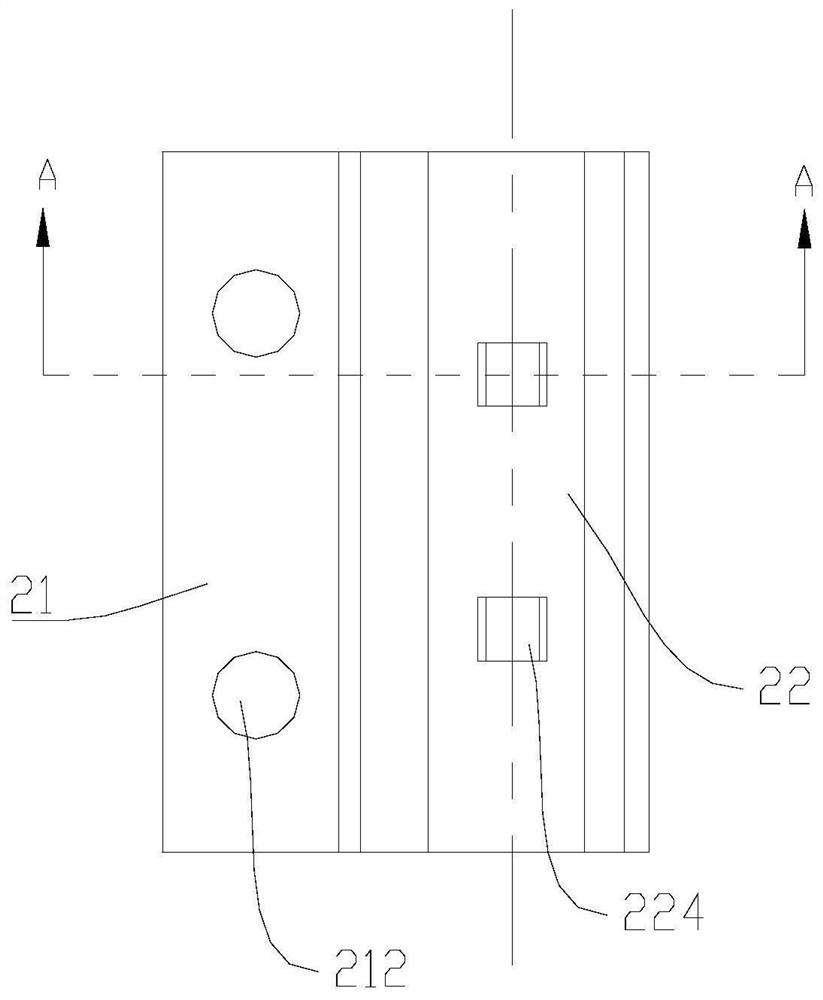

[0051] In this embodiment, a projection 224 is used instead of the pulse axial sliding structure in the first embodiment. In Figure 5 with Figure 6 As shown as an example, the inwardly extending slide 225 is connected to the inner concave surface 223 of the cover 22. A angle between the inclined 225 and the inner concave surface 223 is formed to provide a certain residuality for the leaning 225.

[0052] The slide 225 can further prevent the temperature of the temperature of the temperature of the thermostat from the pressure cover from the pressing cover by an increased pressure, in addition to the convex 224 in the first embodiment. Specifically, for the purpose of reaching such, the inclined extension direction of the linker 225 is inwardly inwardly and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com