Intelligent steel strand tension value correction and calculation method with grating embedded in core wire

An intelligent steel strand, correction and calculation technology, applied in the direction of force/torque/power measuring instrument calibration/testing, instruments, measuring devices, etc., can solve the problems that cannot represent the average strain value of steel wire, deformation coordination, etc., and achieve the concept of mechanics Clear, accurate and reliable results, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

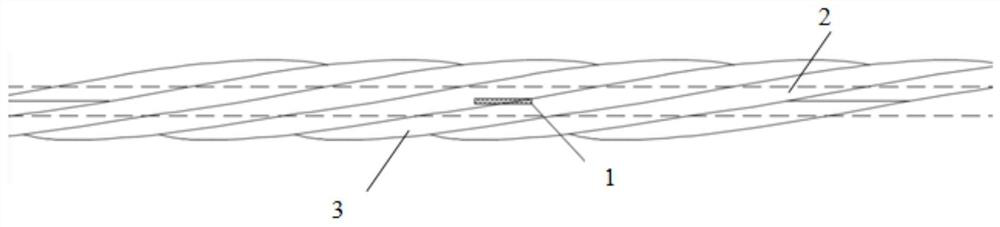

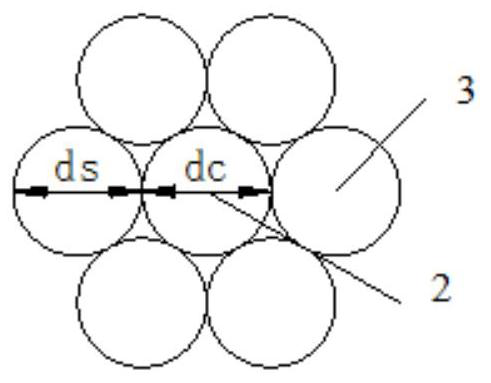

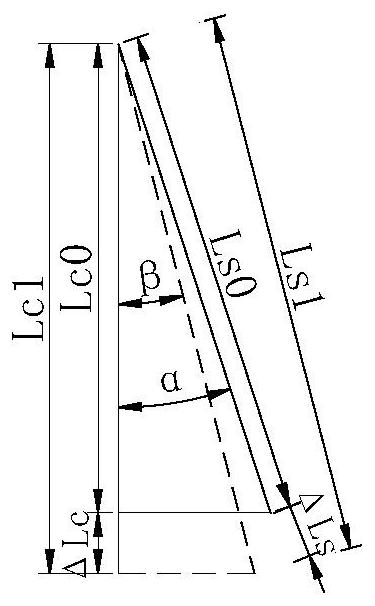

[0032] A commercial smart steel strand with a length of 1.4 m and a core wire diameter d c0 =5.2mm, winding wire diameter d s =5.05mm, lay length L c0 =225mm, elastic modulus E s =1.95×10 5 Mpa, Poisson's ratio μ = 0.3, the core wire and the winding wire of the steel strand are made of the same material.

[0033] This test only verifies the test value of the strain of the core wire of the steel strand and the verification result of the tensile force of the tensile machine. According to the need, follow the steps below:

[0034] 1) Clamp both ends of the purchased smart steel strand on the fixture of the tensile testing machine;

[0035] 2) Connect the other end of the grating in the steel strand to be tested to the modem;

[0036] 3) Start the tensile testing machine for the loading test. In order to understand the stability of the test results, this test adopts the method of loading in stages, and the tensile forces are 0.15F, 0.25F, 0.35F, 0.45F, 0.5F, 0.55F, 0.6 F, 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com