Machine vision-based paddle shadow transfer printing defect identification method

A machine vision, defect recognition technology, applied in character and pattern recognition, optical testing flaws/defects, instruments, etc., can solve the problems of single judgment standard, low product qualification rate, unqualified, etc., to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

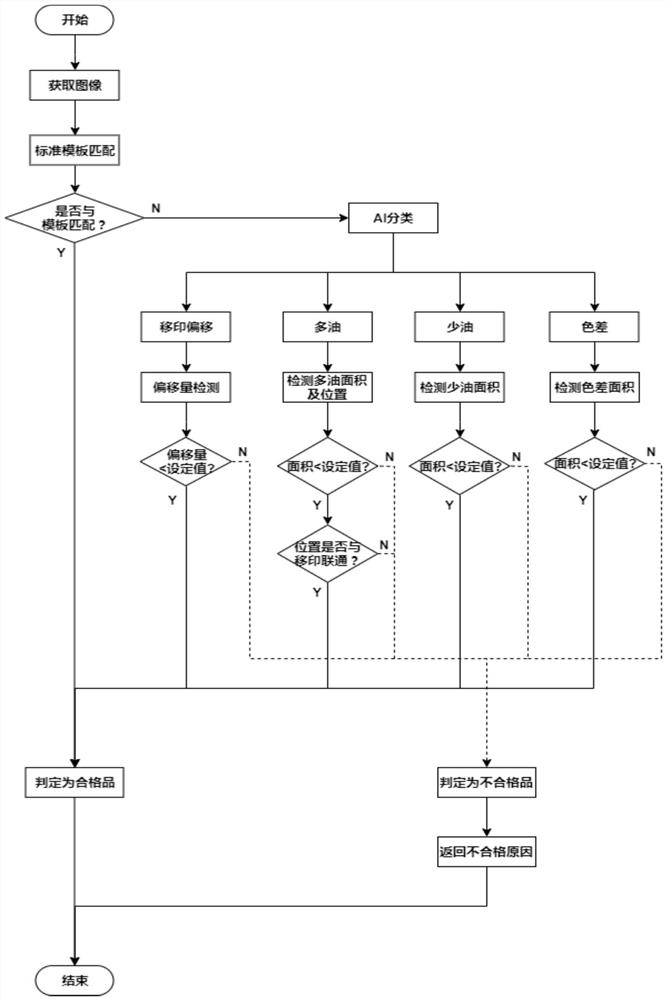

[0030] Such as figure 1 A method for identifying paddle shadow pad printing defects based on machine vision is shown, comprising the following steps:

[0031] Step 1. Use the dome LED diffuse reflector to illuminate the product, and take pictures of the product with an industrial area array color camera with 5 million pixels to obtain the image of the product's blade to be tested.

[0032] Step 2. Use standard template matching to identify standard qualified products and generalized unqualified products, including the following steps:

[0033] Step 2.1, using the contour line of the product in the standard qualified product image, the contour line of the pad printing graphic and the gray value of the pad printing graphic as the conditions for matching the standard template;

[0034] Step 2.2, performing grayscale and Gaussian filtering preprocessing on the acquired image;

[0035] Step 2.3, using the method of edge extraction to obtain the contour line of the product shape, ...

Embodiment 2

[0056] A method for recognizing paddle shadow pad printing defects based on machine vision, comprising the following steps:

[0057] Step 1. Use the dome LED diffuse reflector to illuminate the product, and take pictures of the product with an industrial area array color camera with 5 million pixels to obtain the image of the product's blade to be tested.

[0058] Step 2. Use standard template matching to identify standard qualified products and generalized unqualified products, specifically including the following steps:

[0059] Step 2.1, using the contour line of the standard qualified product image, the contour line of the paddle shadow pad printing figure and the model number character of the product as the matching conditions;

[0060] Step 2.2, preprocessing the acquired image, that is, using a median filter to remove certain noise interference on the image;

[0061] Step 2.3, using the method of edge extraction to obtain the contour line of the product shape, and usin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com