Quantum dot device and preparation method thereof

A quantum dot device and quantum dot technology, applied in the field of quantum dot devices and their preparation, can solve problems such as relying on high-resolution display

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

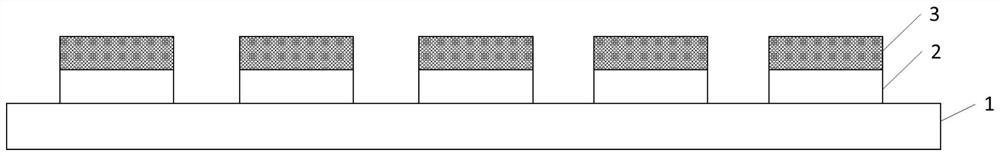

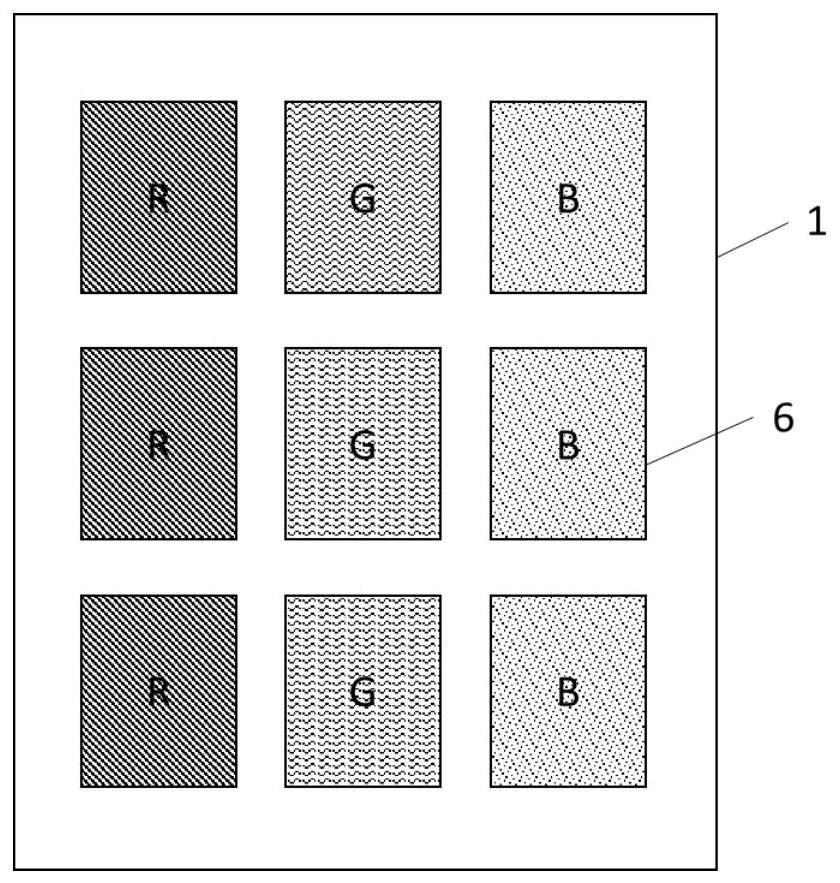

[0031] According to a first aspect of the present disclosure, a method for preparing a quantum dot device is provided, the method comprising:

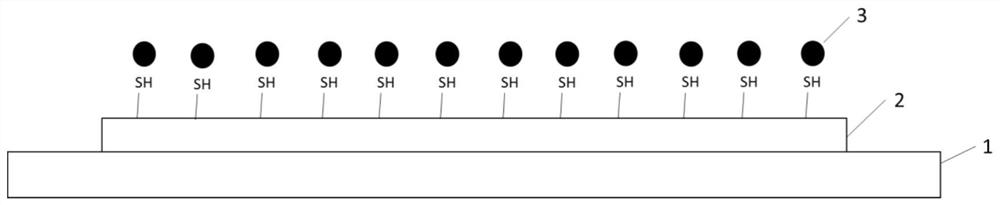

[0032] S1, disposing a photosensitive material on the substrate, the photosensitive material has a first group that can be crosslinked with each other and a second group that can be coordinated with the quantum dot;

[0033] S2, using a mask to expose and develop the photosensitive material, washing and removing the uncured photosensitive material, the first groups are cross-linked and polymerized to form a plurality of cured polymer anchor layers spaced apart from each other;

[0034] S3, setting the quantum dot composition on the substrate with the anchoring layer, the quantum dots in the quantum dot composition are coordinated with the second group to obtain multiple quantum dot layers anchored by the anchoring layer.

[0035] The mask plate has a specific shape and arrangement of hole-like pattern areas and masking areas, so that t...

example 1

[0068] S1. Prepare ITO glass

[0069] Put the ITO glass piece with the number engraved on the back into a glass dish filled with ethanol solution, and wipe the ITO surface clean with a cotton swab. Sonicate with acetone, deionized water, and ethanol in turn for 10 minutes, and blow dry with a nitrogen gun. Finally, place the cleaned ITO glass in oxygen plasma for 10 minutes.

[0070] S2. Preparation of Hole Injection Layer (HIL)

[0071] Spin-coat the cleaned ITO glass slides with Pedot:PSS in air at a rotational speed of 3000r / min and a spin-coating time of 45 seconds. After the spin coating is completed, place it in the air for annealing, the annealing temperature is 150° C., and the annealing time is 30 minutes. After the annealing was completed, the slides were quickly transferred to a glove box under a nitrogen atmosphere.

[0072] S3. Preparation of hole transport layer (HTL)

[0073] TFB (8-10mg / mL, chlorobenzene solution) Continue to spin-coat the glass / ITO / Pedot:...

example 2

[0082] The difference from Example 1 is S4-S5.

[0083] S41. Preparation of anchoring layer (TAL)

[0084] The photosensitive material 4-(vinyl)benzenemethanol (1mg / mL, ethanol solution) was spin-coated on the substrate prepared in the previous steps at 2000r / min, and the spin-coating time was 45 seconds. Use a mask to expose the photosensitive material (365 nm portable ultraviolet lamp for 10 min), and then use ethanol to spin coat and clean to obtain a patterned anchor layer.

[0085] S51. Preparation of quantum dot luminescent layer

[0086] Red light CdSe-CdS core-shell quantum dots (ligand is oleic acid), the optical density (OD) of the former is 70-80 at 400nm, dissolved in octane solvent. After annealing the glass / ITO / Pedot:PSS / HTL / TAL sheet, continue to spin-coat the quantum dot solution, the spin-coating speed is 2000r / min, and the spin-coating time is 45 seconds. Anneal at 60°C for 30min after spin coating. After the annealing is completed, it is cleaned by spin-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com