Optimal design method for main frame of wind turbine generator based on deformation technology

A wind turbine, optimization design technology, applied in computer-aided design, design optimization/simulation, calculation, etc., can solve problems such as self-heavy, long design cycle of the main frame, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

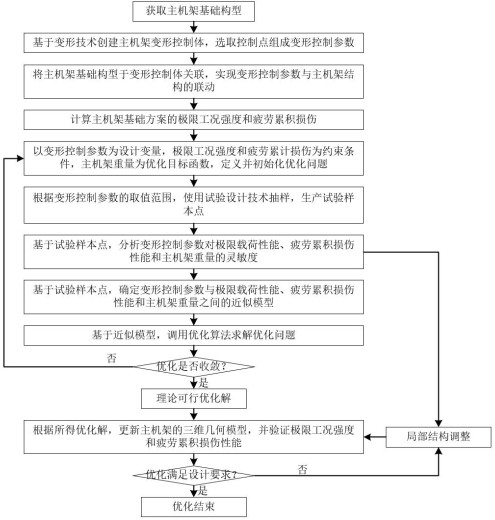

[0029] see Figure 1~5 As shown, the present invention provides a method for optimizing the design of the wind turbine main frame based on deformation technology, including the following steps:

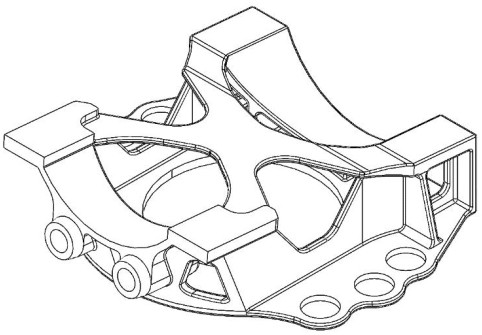

[0030] first step, such as figure 2 As shown, the three-dimensional geometric model of the main frame in the basic design stage is obtained as the optimized basic configuration of this embodiment, and the main frame already has a basic structural shape.

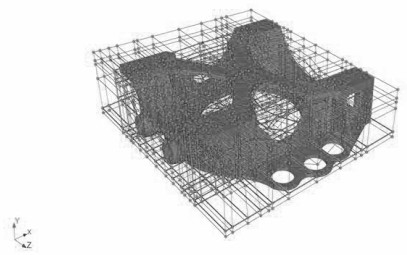

[0031] The second step, such as image 3 As shown, use the deformation technology in the professional deformation tool to create a three-dimensional deformation contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com