A high-efficiency corn cob threshing device

A threshing device and corn crushing technology, applied in threshing equipment, agriculture, applications, etc., can solve problems such as difficulty in ensuring the stability of corn crushed cobs, increasing the probability of damage to corn kernels, and failure to maintain clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

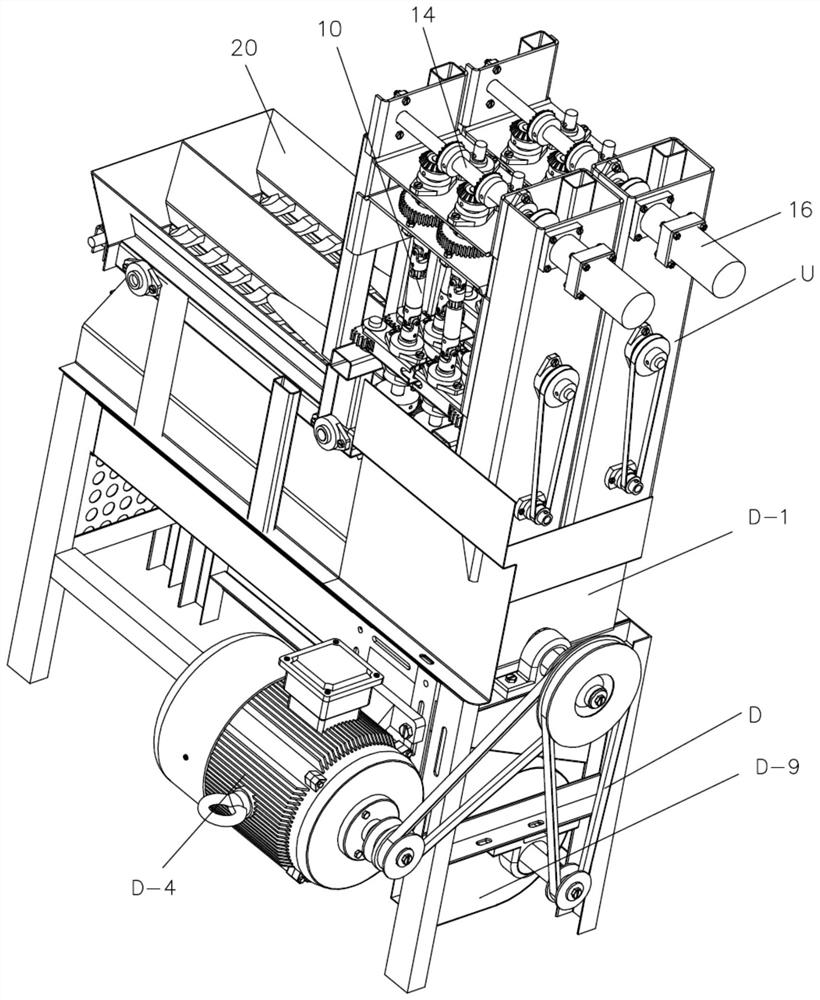

[0035] The basic structure of the high-efficiency corn cob threshing device of the present embodiment is as follows: figure 1 As shown, it includes a broken core mechanism U and a threshing mechanism D located at the upper and lower parts of the frame respectively. Among them, two broken core mechanisms are connected in parallel.

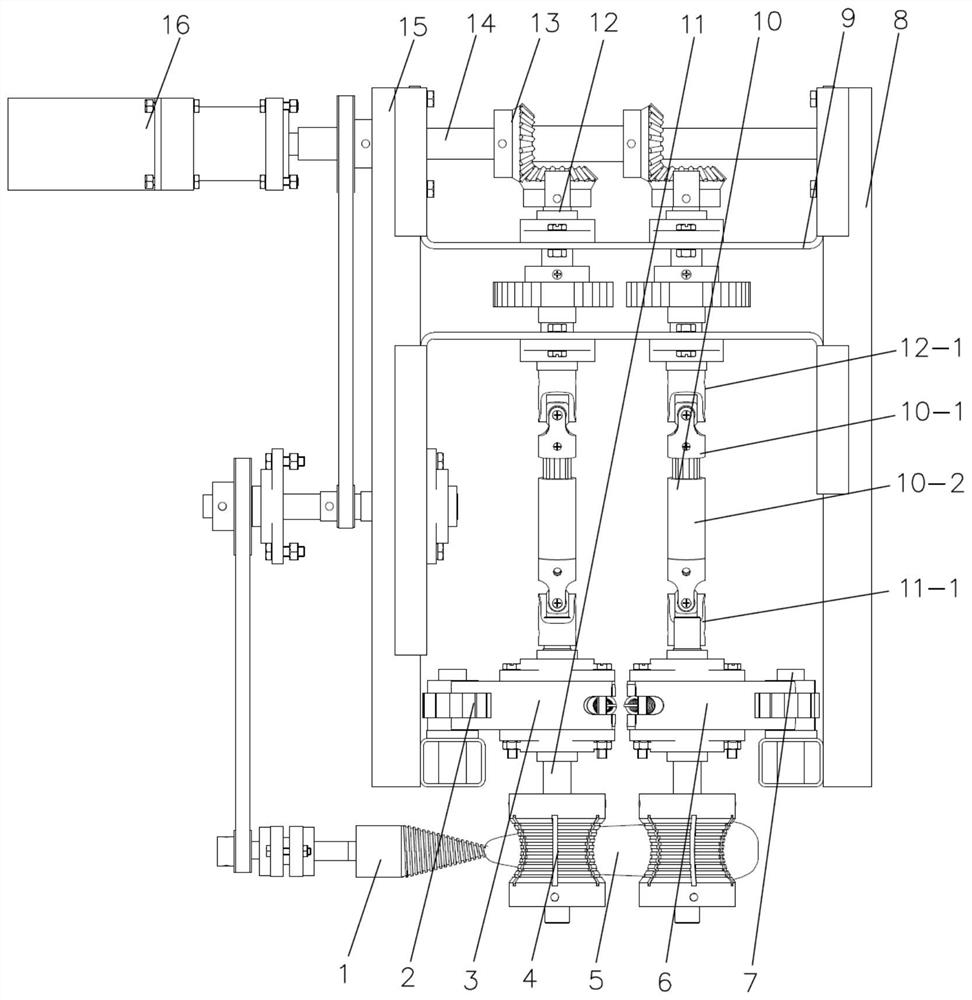

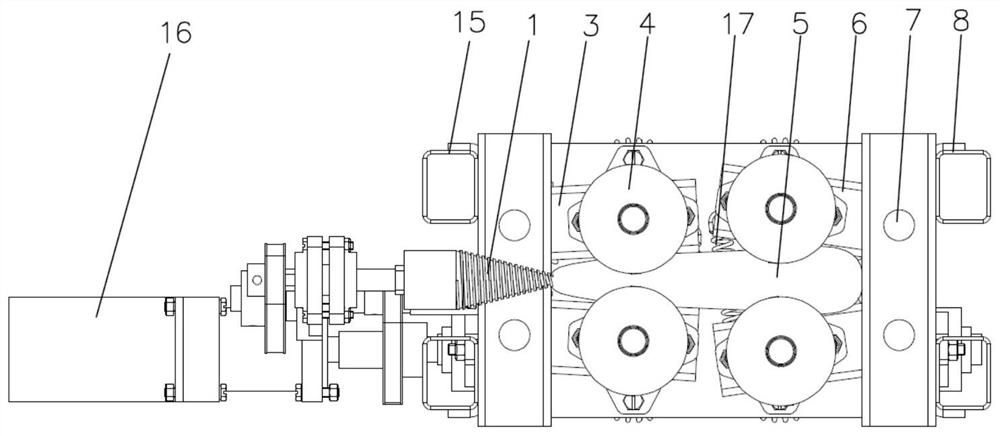

[0036] The specific structure of the broken core mechanism U is as follows: Figure 2 to Figure 5Shown, comprise front and rear struts 15,8 that are fixedly connected with the frame, the bottom of front and rear struts 15,8 are respectively hinged by vertical pin 7 and stretch forward left and right hinged plates 6 and stretch left and right. The right hinged plate 3, the hinges of the forward left and right hinged plates 6 and the rearward stretched left and right hinged plates 3 are respectively fixedly connected with the corresponding synchronous meshing gears 2, and the forward left and right hinged plates 6 and the rear The cantilever ends of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com