Hydrocracking method for improving aromatic potential of heavy naphtha

A technology for hydrocracking and heavy naphtha, which is applied in the petroleum industry, hydroprocessing process, and hydrocarbon oil treatment, and can solve the problems of energy consumption and poor economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

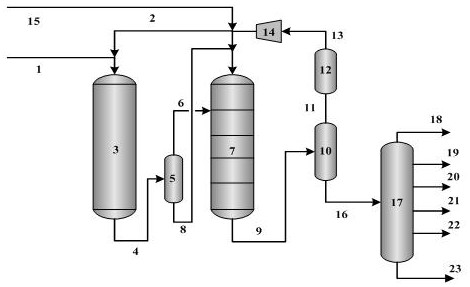

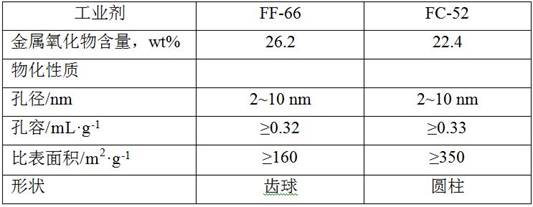

Method used

Image

Examples

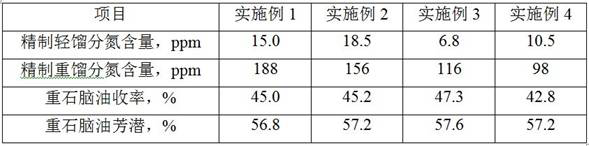

Embodiment 1

[0043] The average temperature of the hydrofinishing reactor is 356°C, the cut point of the light and heavy fraction is 480°C, and the space velocity of the hydrofinishing agent in the hydrocracking reactor is 6.0 h -1 , the hydrocracking agent space velocity is 1.8h -1 . The light fraction enters the inlet of the second reaction zone of the hydrocracking reactor, and the heavy fraction directly enters the inlet of the hydrocracking reactor. Other process conditions are shown in Table 3.

Embodiment 2

[0045] The average temperature of the hydrofinishing reactor is 356°C, the cut point of the light and heavy fraction is 500°C, and the space velocity of the hydrofinishing agent in the hydrocracking reactor is 8.0 h -1 , the hydrocracking agent space velocity is 1.8h -1 . The light fraction enters the inlet of the second reaction zone of the hydrocracking reactor, and the heavy fraction directly enters the inlet of the hydrocracking reactor. Other process conditions are shown in Table 3.

Embodiment 3

[0047] The average temperature of the hydrofining reactor is 360 °C, the cut point of the light and heavy fraction is 480 °C, and the space velocity of the hydrofinishing agent in the hydrocracking reactor is 6.0 h -1 , the hydrocracking agent space velocity is 1.8h -1 . The light fraction enters the inlet of the second reaction zone of the hydrocracking reactor, and the heavy fraction directly enters the inlet of the hydrocracking reactor. Other process conditions are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com