Ceramic Reinforced fe-cr-b Alloy Composite Material and Its Application and Preparation

A technology of composite materials and alloy materials, applied in the field of ceramic reinforced Fe-Cr-B alloy composite materials, to achieve the effect of improving the protection coefficient, low cost and good impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

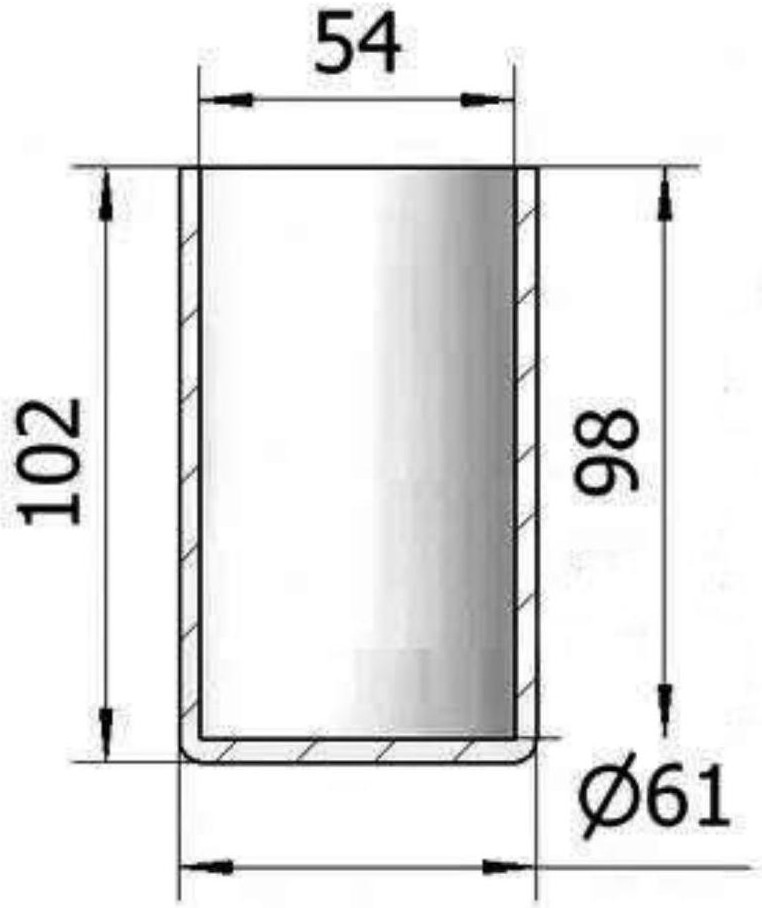

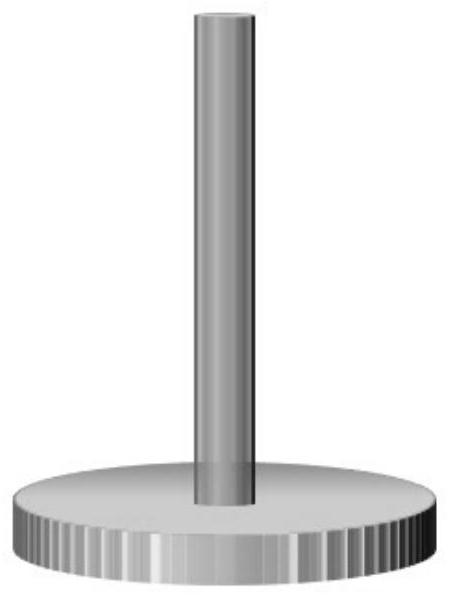

[0065] A bulletproof metal-ceramic composite plate, which adopts a ceramic reinforced Fe-Cr-B alloy composite material to prepare a bulletproof composite armor plate, which can be used for armored vehicles; the ceramic reinforced Fe-Cr-B alloy composite material includes a metal ceramic composite material reinforced block 1 and casting Fe-Cr-B alloy 2;

[0066] The Fe-Cr-B alloy for casting includes: (1) The chemical components contained and the mass percentages of each component are: Si: 0.1%, Mn: 2%, Cr: 18%, B: 0.1%, C: 3%, The balance is Fe and unavoidable impurities; (2) Armor steel, such as 675 armor steel, 30CrNiMnMoB high-strength armor steel, etc. In the present embodiment, what adopt is casting Fe-Cr-B alloy;

[0067] According to the volume ratio, metal-ceramic composite reinforced block: Fe-Cr-B alloy for casting = 1:5;

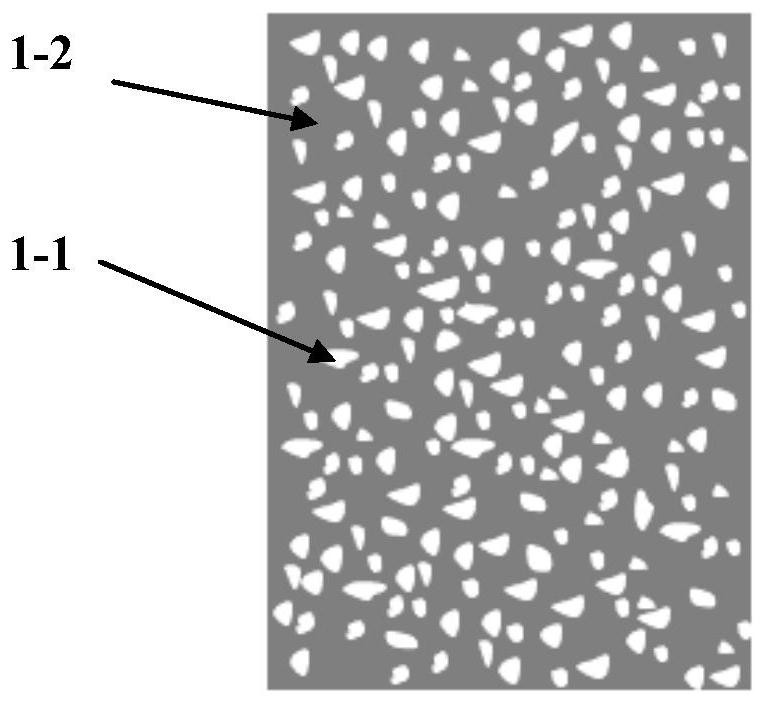

[0068] The metal-ceramic composite reinforced block 1 includes ceramic reinforced particles (ZTA balls 1-3 in this embodiment) and Fe-Cr-B matr...

Embodiment 2

[0094] A wear-resistant metal-ceramic composite plate, which is a ceramic-reinforced Fe-Cr-B alloy composite material to prepare a wear-resistant metal-ceramic composite blow bar, and the ceramic-reinforced Fe-Cr-B alloy composite material includes a metal-ceramic composite reinforced block 1 and Fe-Cr-B alloy for casting 2; by volume ratio, cermet composite reinforced block: Fe-Cr-B alloy for casting = 1:1.5;

[0095] The chemical composition and the mass percentage of each composition contained in the Fe-Cr-B alloy for casting are: Si: 0.1%, Mn: 7%, Cr: 10%, B: 5%, C: 0.2%, W: 7%, Ti: 3%, the balance is Fe and unavoidable impurities;

[0096] The metal-ceramic composite reinforcement block 1 includes ceramic reinforcement particles (ZTA particles 1-1 in this embodiment) and Fe-Cr-B matrix alloy powder 1-2; the ceramic reinforcement particles are used as a reinforcement phase, and the The above-mentioned Fe-Cr-B matrix alloy powder is used as the matrix, and by volume ratio,...

Embodiment 3

[0118] A bullet-proof metal-ceramic composite board, which uses a ceramic-reinforced Fe-Cr-B alloy composite material to prepare a bullet-proof metal-ceramic composite board, which can be used for bunkers, wherein the ceramic-reinforced Fe-Cr-B alloy composite material includes a metal-ceramic composite material reinforcing block Body 1 and casting Fe-Cr-B alloy 2; wherein, by volume ratio, cermet composite reinforced block: casting Fe-Cr-B alloy = 1:1.5;

[0119] The chemical composition and the mass percentage of each composition contained in the Fe-Cr-B alloy for casting are: Si: 2.5%, Mn: 0.1%, Cr: 10%, B: 1%, C: 1%, W: 7%, Mo: 6%, the balance is Fe and unavoidable impurities;

[0120] The metal-ceramic composite reinforced block 1 includes ceramic reinforced particles (ZTA balls 1-3 in this embodiment) and Fe-Cr-B matrix alloy powder 1-2; the ceramic reinforced particles are used as a reinforcing phase, and the The above-mentioned Fe-Cr-B matrix alloy powder is used as t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com