A kind of asphalt multi-tube foaming system and process

A foaming system and asphalt technology, applied in the field of asphalt production, to achieve the effects of reducing harmful gas emissions, high foaming multiples, and long half-life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Specific embodiments of the present invention will be described below with reference to the accompanying drawings. Numerous details are described below in order to provide a thorough understanding of the present invention, but for those skilled in the art, the present invention may be practiced without these details. Well-known components, methods, and procedures are not described in detail below.

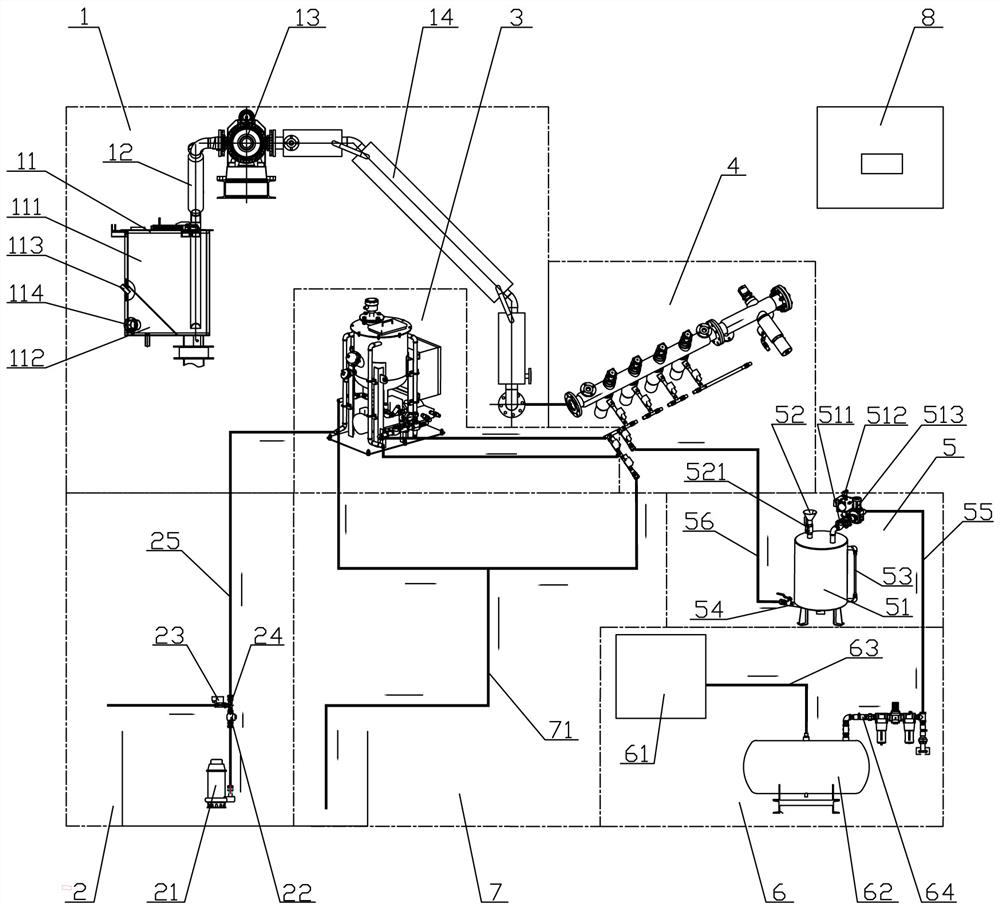

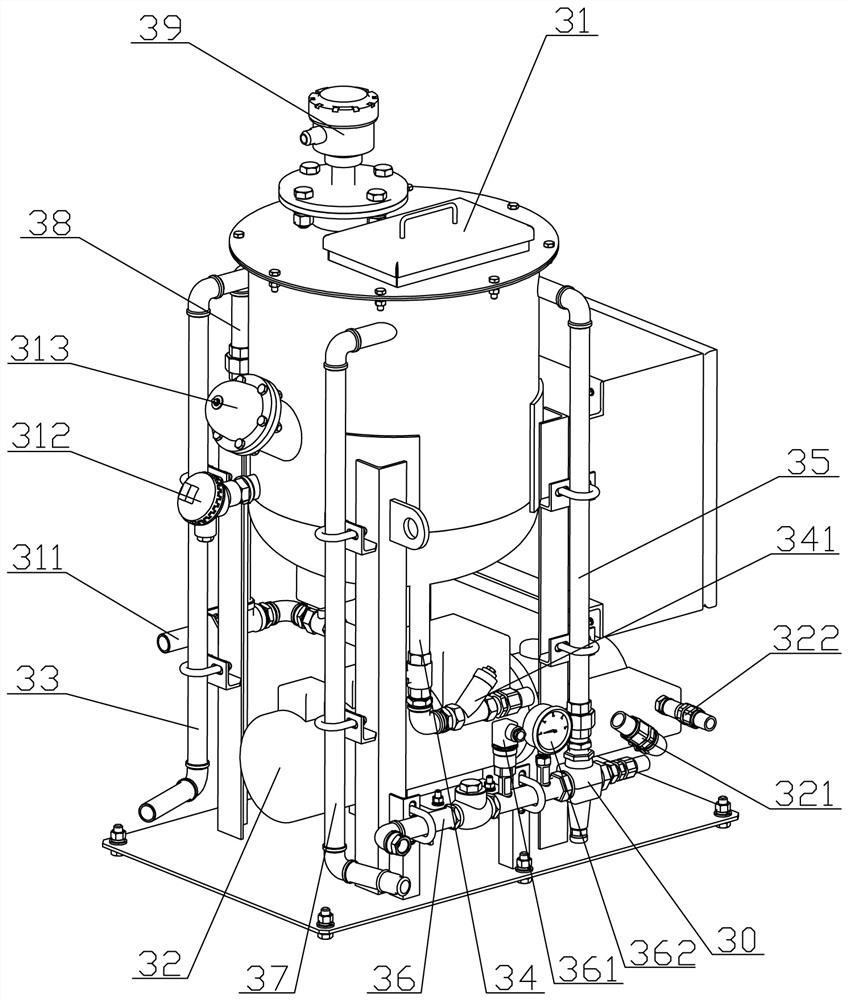

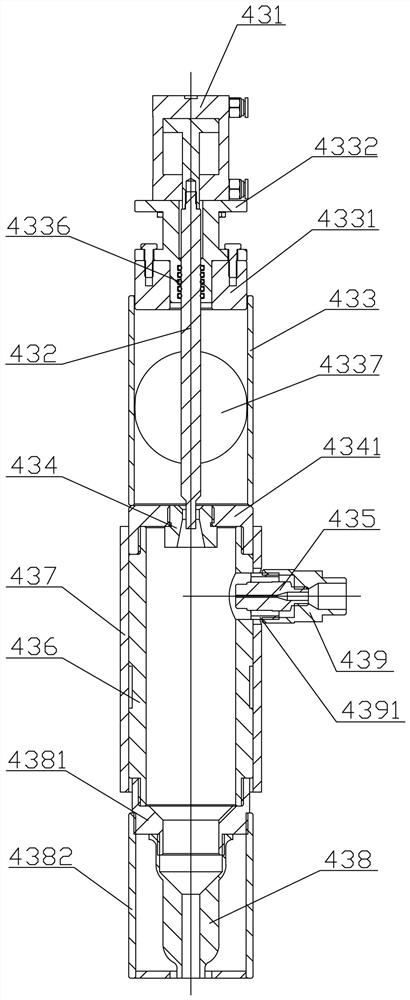

[0029] An asphalt multi-tube foaming system, refer to figure 1 , including an asphalt supply module 1, a ground water supply module 2, a high-pressure water supply module 3, a multi-tube foaming module 4, a diesel cleaning module 5, an air supply module 6, a drainage module 7 and an electrical control module 8.

[0030] refer to figure 1 , the asphalt supply module mainly includes an asphalt metering barrel 11, an asphalt inlet pipeline 12, a screw pump 13, and an asphalt outlet pipeline 14. The inlet end of the screw pump 13 is connected to the asphalt metering barrel 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com