Air Floating Thrust Bearing Based on Coplanar Load Suction of Outer Rings

A thrust bearing and air-floating shaft technology, which is applied in the field of air-bearing thrust bearings based on the coplanar load absorption of the outer ring, can solve problems such as poor bearing performance, improve accuracy, stability and reliability, and avoid frictional increase. Large, the effect of improving the load-carrying characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creation features, achievement goals and effects of the present invention easy to understand and understand, the present invention will be further described below with reference to the specific embodiments.

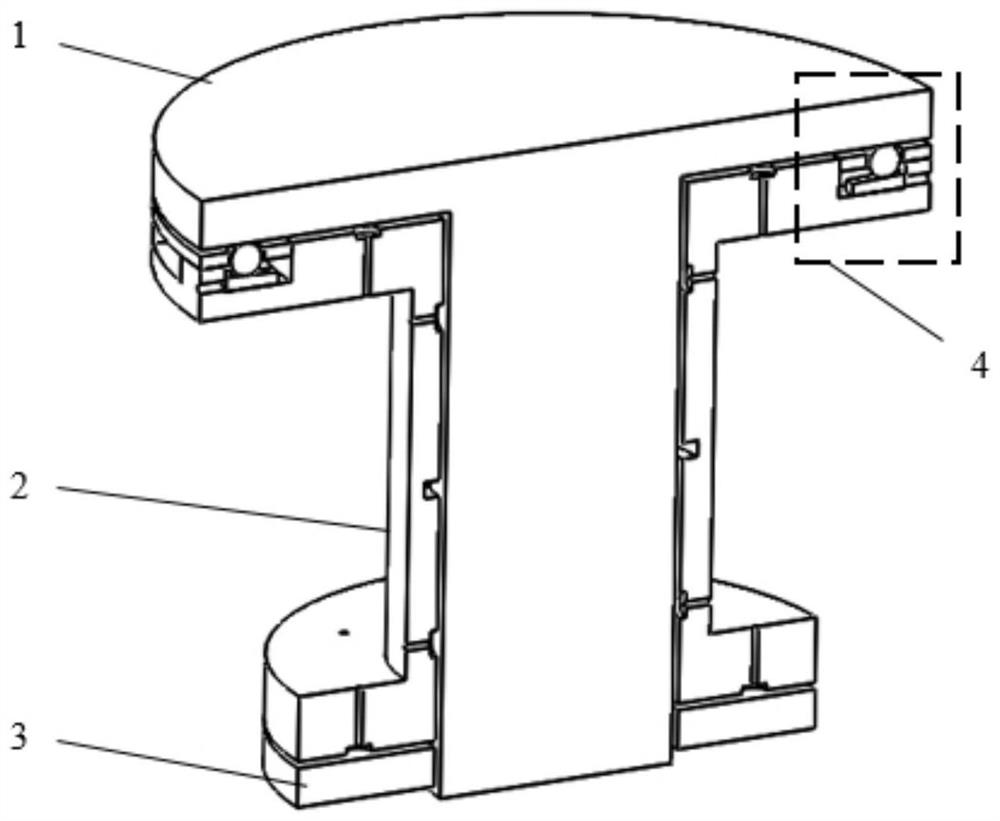

[0024] refer to figure 1 , Based on the coplanar suction load of the outer ring, the air-floating thrust bearing includes an air-floating shaft 1, an air-floating sleeve 2, a thrust plate 3 and a suction-loading device 4. The air-bearing shaft 1 is T-shaped, and the air-bearing shaft is air-floated. The shaft 1 and the thrust plate 3 are installed on both sides of the air flotation sleeve 2 and fit with the air flotation sleeve 2 in a clearance fit.

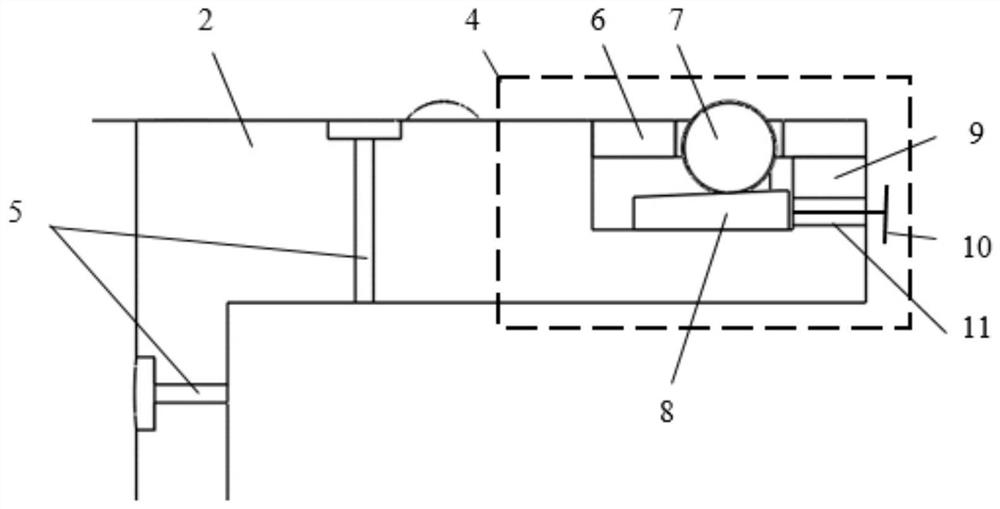

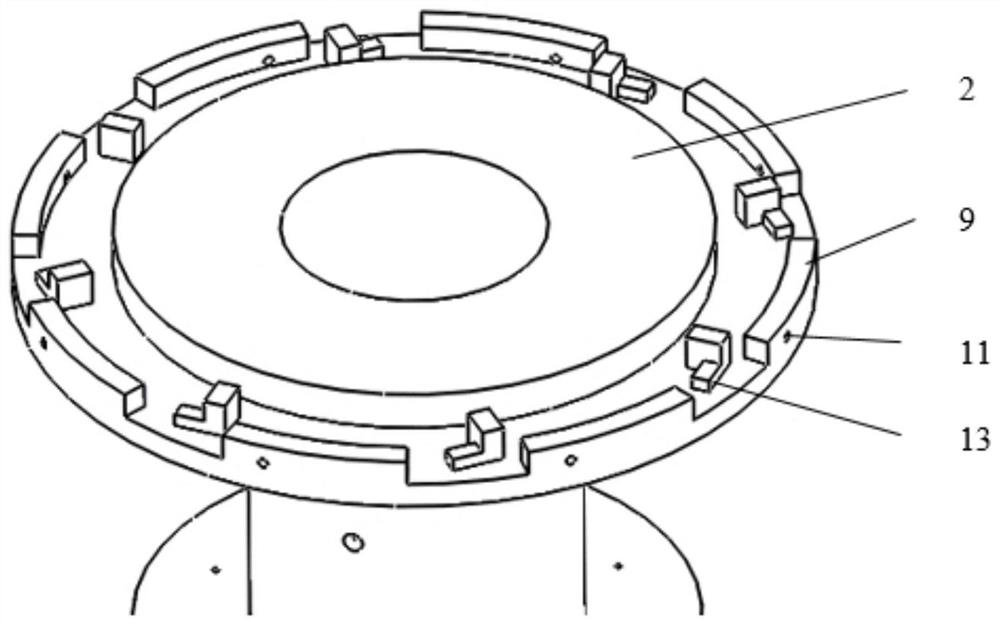

[0025] refer to figure 2 , a number of restrictors 5 are installed on the air flotation sleeve 2, and the installation direction of the restrictor 5 is both radial and axial; The specific structure of the suction-loading device 4 is as follows: the suction-loading device 4 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com