Production process and production device for silk-screen scratch-resistant liquid crystal display screen of electronic watch

A liquid crystal display and production device technology, applied in the direction of nonlinear optics, instruments, optics, etc., can solve the problems of inconvenient streamlined processing production, unfavorable processing production, unfavorable processing settings, etc., to achieve convenient cycle work, clean surface and convenient The effect of process treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

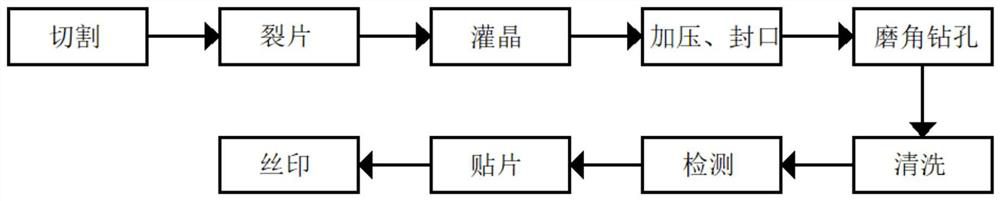

[0055] The production process of screen printing and anti-scratch electronic watch liquid crystal display, such as figure 1 shown, including the following steps:

[0056] S1. Cutting: use the glass cutting knife wheel to cut large pieces of glass liquid crystal cells into liquid crystal cell strips or liquid crystal cell particles;

[0057] S2. Slivers: Use uniform pressure to neatly break the cut liquid crystal cell strips or liquid crystal cells into smaller pieces along the cutting line;

[0058] S3. Filling: Using the principle of vacuum pressure difference, the empty liquid crystal box that has been evacuated is inverted on the tank filled with liquid crystal, and the liquid crystal is poured into the box by the pressure difference generated after the air is inflated outside the empty box;

[0059] S4. Pressurization and sealing: use the pressure to level the deformation of the liquid crystal cell caused by the liquid crystal filling process, and seal the injection port ...

Embodiment 2

[0078] On the basis of Example 1, such as Figure 11 As shown, the cleaning structure 23 also includes a conduction pipe 41, a conduction branch pipe 42 and a spray rack 43. The conduction pipe 41 is arranged at the bottom position of the inner end of the cleaning structure 23, and the upper end of the conduction pipe 41 communicates with the conduction branch pipe 42, and the conduction branch pipe 42 The top position of the top is communicated with the spray frame 43 and arranged.

[0079] When this embodiment is in use, the user can transmit the cleaning agent through the conduction branch pipe 42, so that the cleanser can be conducted through the conduction pipe 41, arrive at the position of the conduction branch pipe 42, and pass through the top position of the spray rack 43 and the bottom of the cleaning pool 34. The inner end is connected to realize the feeding of the inner end, and drives the flow of the inner end cleaning agent, and the conduction branch pipe 42 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com