Liquid crystal composite film, preparation method thereof and liquid crystal writing board

A composite film and liquid crystal technology, applied in instruments, optics, nonlinear optics, etc., can solve the problems of single color, poor contrast, slow response speed, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

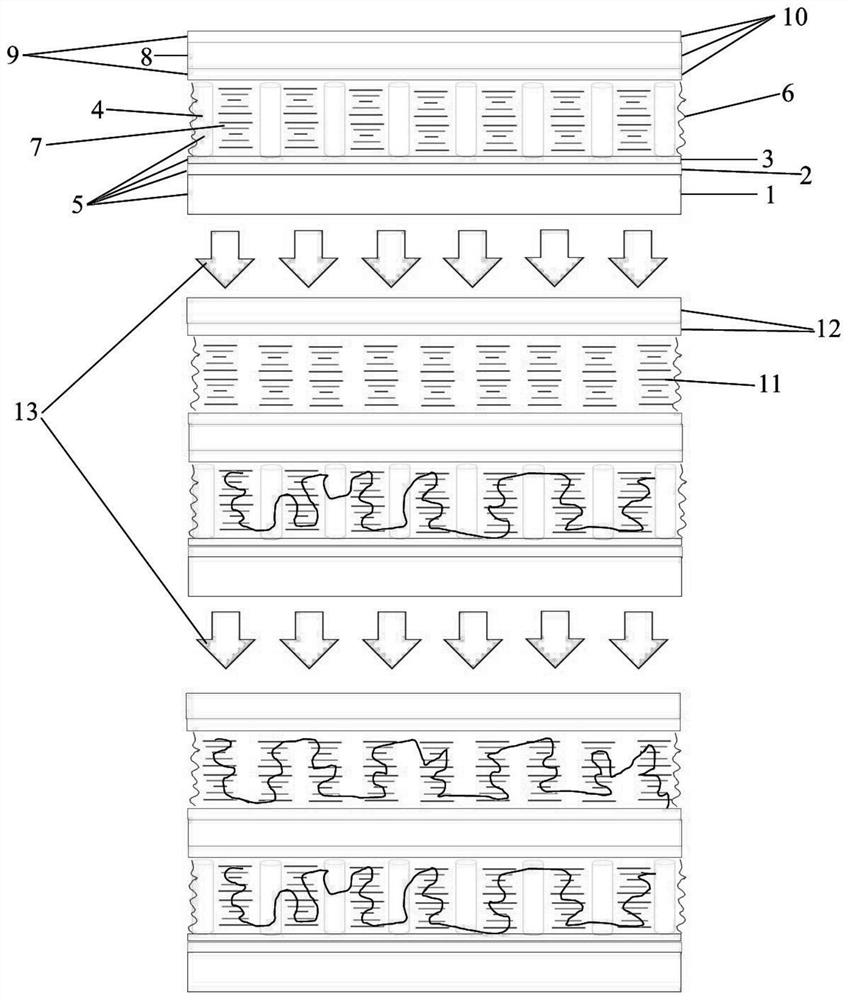

[0063] as attached figure 1 As shown, this embodiment provides a kind of two-color / double-layer liquid crystal composite film, comprises the first layer PET film 12 that is plated with ITO conductive layer on one side connected successively from top to bottom, the first layer of polymer liquid crystal composite layer 11. The second layer of PET film 10 coated with ITO conductive layer on both sides, the second layer of polymer liquid crystal composite layer 7, and the third layer of thin glass layer 5 with insulating layer and TFT layer on one side.

[0064] Specifically, the thickness of the first layer of PET film is 25 μm, the light transmittance is 96%, the transverse heat shrinkage rate is 0.05%, the longitudinal heat shrinkage rate is 0.05%, the resistance value of the ITO conductive layer is 15Ω, and the light transmittance 96%.

[0065] The upper surface of the first layer of PET film (that is, the first base layer) has a hardened layer with anti-ultraviolet function....

Embodiment 2

[0098] This embodiment provides a kind of two-color / double-layer liquid crystal composite film, comprising the first layer of PET film with one side coated with ITO conductive layer connected successively from top to bottom, the first layer of polymer liquid crystal composite layer, double-sided coated The second layer of PET film with ITO conductive layer, the second layer of polymer liquid crystal composite layer, the third layer of thin glass layer with insulating layer and TFT layer on one side.

[0099] The thickness of the first layer of PET film is 180 μm, the light transmittance is 86%, the transverse heat shrinkage rate is 3%, the longitudinal heat shrinkage rate is 3%, the resistance value of the ITO conductive layer is 100Ω, and the light transmittance is 89%. .

[0100] The upper surface of the first layer of PET film has a hardened layer with anti-ultraviolet function. The hardness of the hardened layer is 10H, and the ultraviolet absorber UV-405 is added, and th...

Embodiment 3

[0133] This embodiment provides a kind of two-color / double-layer liquid crystal composite film, comprising the first layer of PET film with one side coated with ITO conductive layer connected successively from top to bottom, the first layer of polymer liquid crystal composite layer, double-sided coated The second layer of PET film with ITO conductive layer, the second layer of polymer liquid crystal composite layer, the third layer of thin glass layer with insulating layer and TFT layer on one side.

[0134] The thickness of the first layer of PET film is 102.5 μm, the light transmittance is 91%, the transverse heat shrinkage rate is 1.5%, the longitudinal heat shrinkage rate is 1.5%, the resistance value of the ITO conductive layer is 57.5Ω, and the light transmittance rate is 1.5%. 92%.

[0135] The upper surface of the first layer of PET film has a hardened layer with anti-ultraviolet function. The hardness of the hardened layer is 6.5H, and the ultraviolet absorber UV-928...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com