Three-dimensional prediction method capable of realizing growth and segregation of steel solidification dendrites

A three-dimensional prediction and three-dimensional technology, applied in special data processing applications, geometric CAD, computer-aided design, etc., to achieve realistic display and processing of images and animations, improve accuracy, and avoid high costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

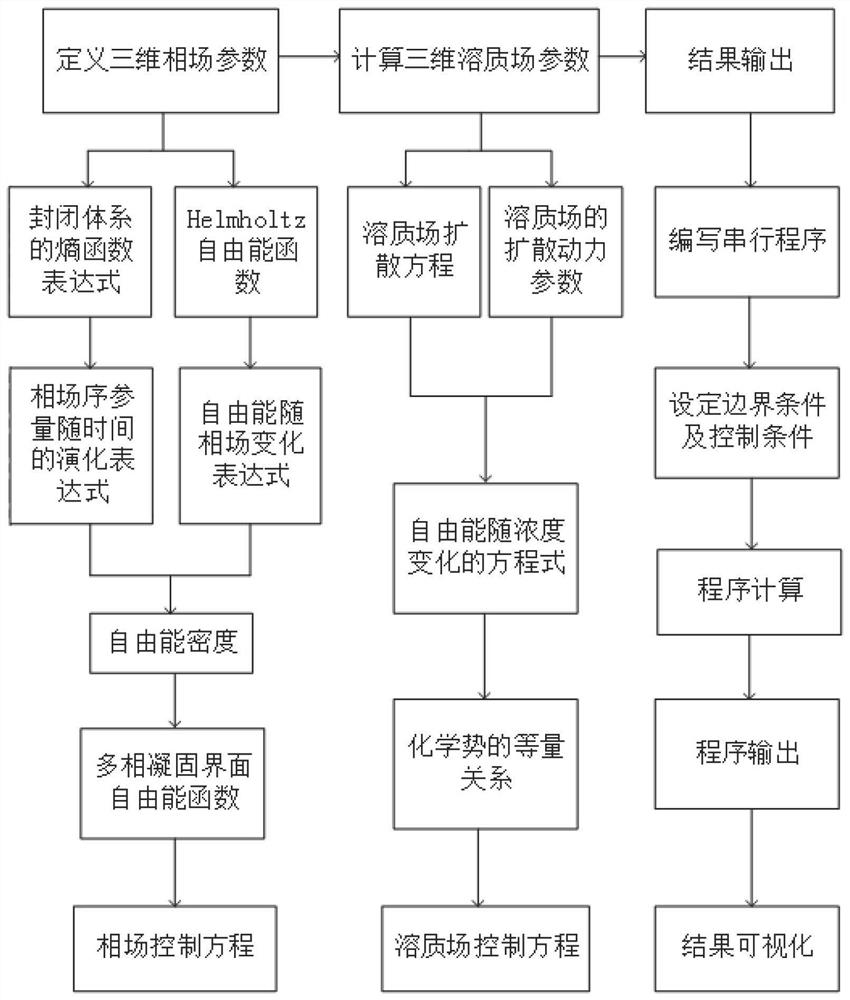

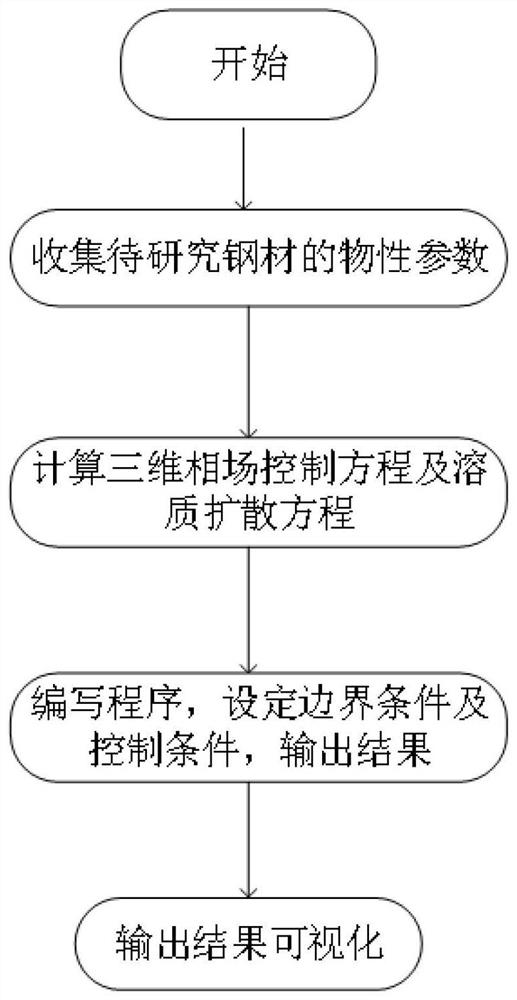

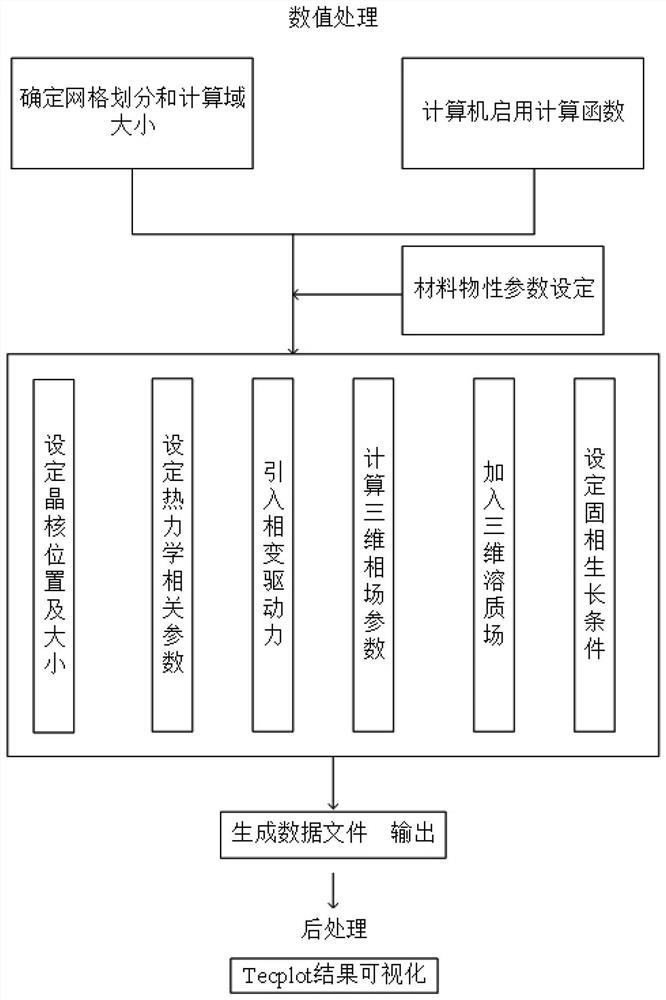

[0046] In this embodiment, the three-dimensional prediction method of the present invention that can realize the growth and segregation of solidified dendrites in steel is used to predict the competitive growth of grains in the production process of a low-carbon peritectic steel sample of a steel plant. like figure 1As shown, a three-dimensional prediction method for steel solidification dendrite growth and segregation can be realized. The three-dimensional prediction method for realizing the growth and segregation of steel solidification dendrites of the present invention comprises the following steps:

[0047] Step 1: Collect the data of the physical property parameters of the steel to be studied and the proportion of each component; the physical property parameters include the liquidus slope, the melting point temperature, and the molar volume.

[0048] In this embodiment, the carbon content of the low carbon peritectic steel sample is 0.83 at.%, and the addition of solute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com