Fuel cell stack performance recovery method and system

A fuel cell stack and recovery method technology, which is applied in the field of fuel cell stack performance recovery methods and systems, can solve the problems of proton membrane hydrogen gas permeability difference, time difference, irreversible attenuation of electrode catalyst carrier, etc., so as to improve the consistency of reaction activity and safety Efficient performance conditions, the effect of fast and efficient recovery of performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

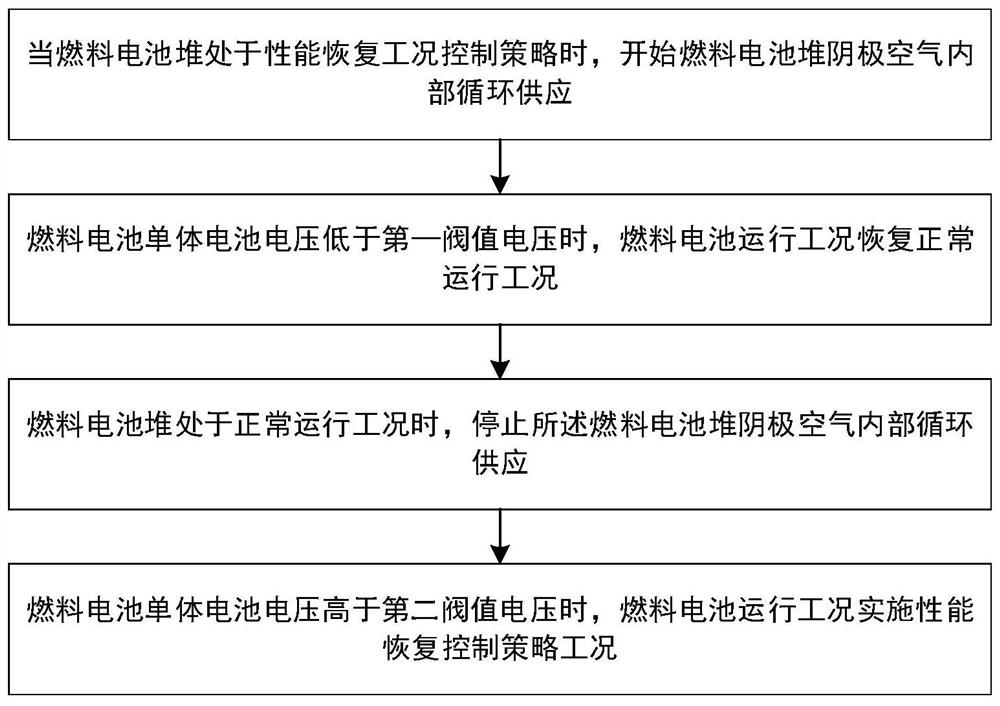

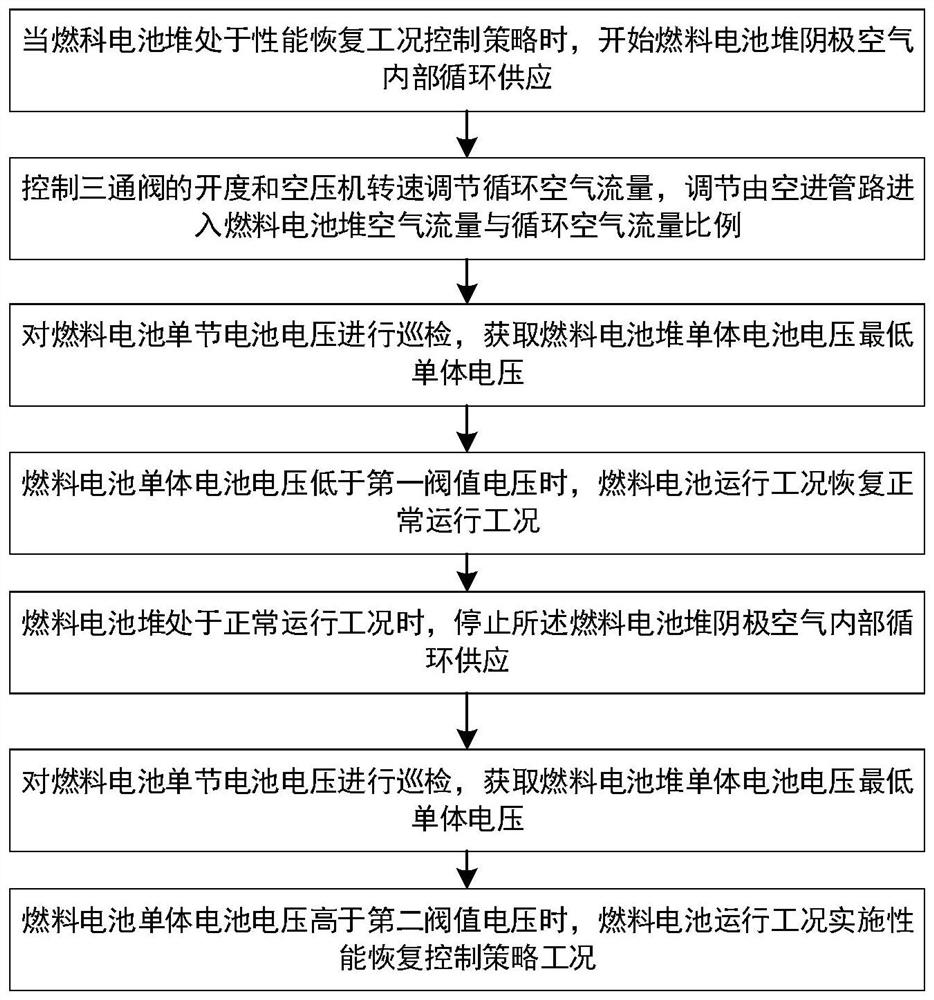

[0031] Embodiment 1 of the present invention provides a fuel cell stack performance recovery method, including the following steps:

[0032] Set up the fuel cell stack cathode air internal circulation supply, and detect the output single cell voltage of the fuel cell stack;

[0033] The fuel cell stack is in the performance recovery condition, and the internal circulation supply of the cathode air of the fuel cell stack is turned on. When it is detected that the voltage of the single cell is lower than the first threshold voltage, the fuel cell stack is switched to the normal operating condition;

[0034] The fuel cell stack is in a normal operating condition, the internal circulation supply of the fuel cell stack cathode air is stopped, and when the voltage of the single cell is detected to be higher than the second threshold voltage, the fuel cell stack is switched to the performance recovery working condition.

[0035] Specifically, when the fuel cell stack is in the perfor...

Embodiment 2

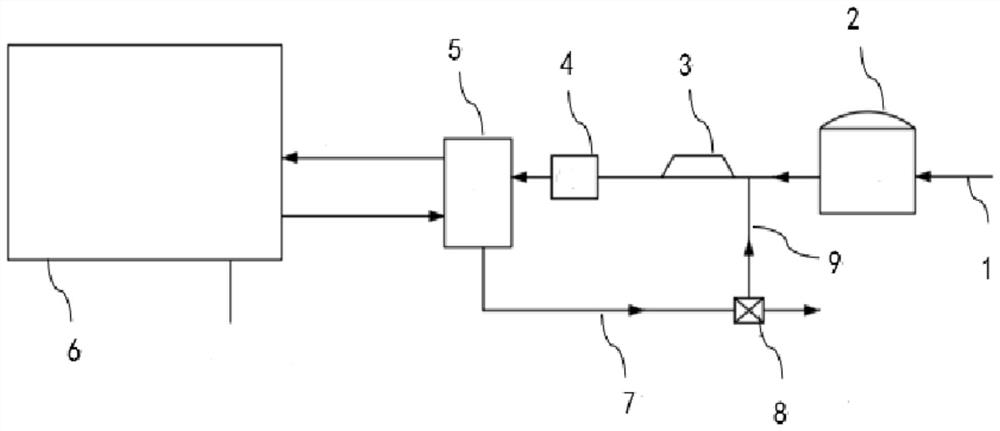

[0039] Embodiment 2 of the present invention provides a fuel cell stack performance recovery system, including a fuel cell stack, a gas supply pipeline, a voltage detection module, and a controller; wherein:

[0040]The air supply pipeline is connected to the cathode of the fuel cell stack and the controller, and is used for supplying air to the cathode of the fuel cell stack and supplying internal circulation of cathode air;

[0041] The voltage detection module is connected to the fuel cell stack and the controller, and is used to detect the output cell voltage of the fuel cell stack and feed back the voltage value to the controller;

[0042] The controller is used to determine whether the output condition of the fuel cell stack is to open the gas supply pipeline to supply the internal circulation of cathode air to switch the operating condition:

[0043] Determine that the fuel cell stack is in the performance recovery condition, control the gas supply line to open the inte...

Embodiment 3

[0050] refer to figure 2 and image 3 , when the fuel cell system executes the performance recovery strategy, the air supply system opens the air tail exhaust circulation valve. Here, the three-way valve 8 is selected to make the tail exhaust air re-enter the stack from the air compressor 3, reducing the oxygen content of the air inside the stack. The self-inspection unit of the system detects the output voltage of the stack. As the reaction continues, the oxygen content of the cathode air of the fuel cell stack 6 further decreases, forming oxygen starvation. The anode hydrogen is "pumped" into the cathode by the hydrogen pump to The oxide film formed on the surface of the cathode catalytic platinum is removed, and the performance of the fuel cell stack 6 is restored according to the removal of the oxide film. By detecting the output cell voltage value of the stack, the control system generates the reaction time of the hydrogen pump. When it is detected that the fuel cell st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com