Unmanned aerial vehicle battery suitable for automatically replacing platform

An automatic battery replacement technology, applied in the field of drones, can solve the problems of inconvenient disassembly and assembly of drone batteries, and achieve the effect of accurate battery replacement process and saving manpower and material resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

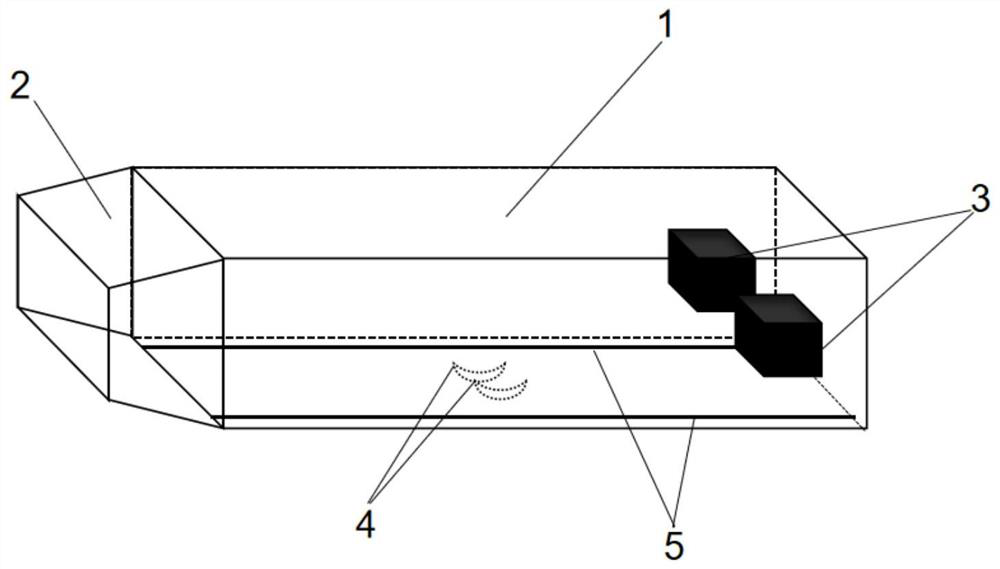

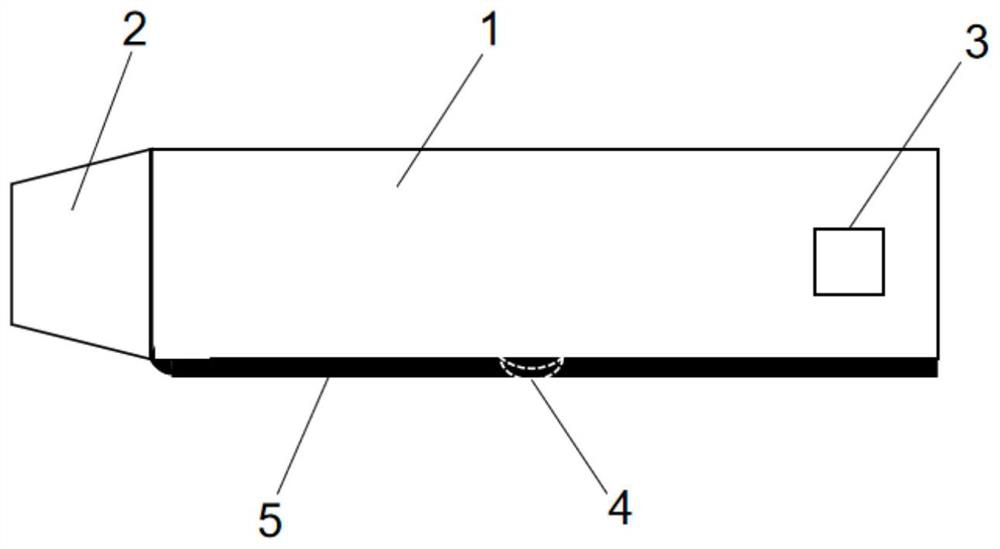

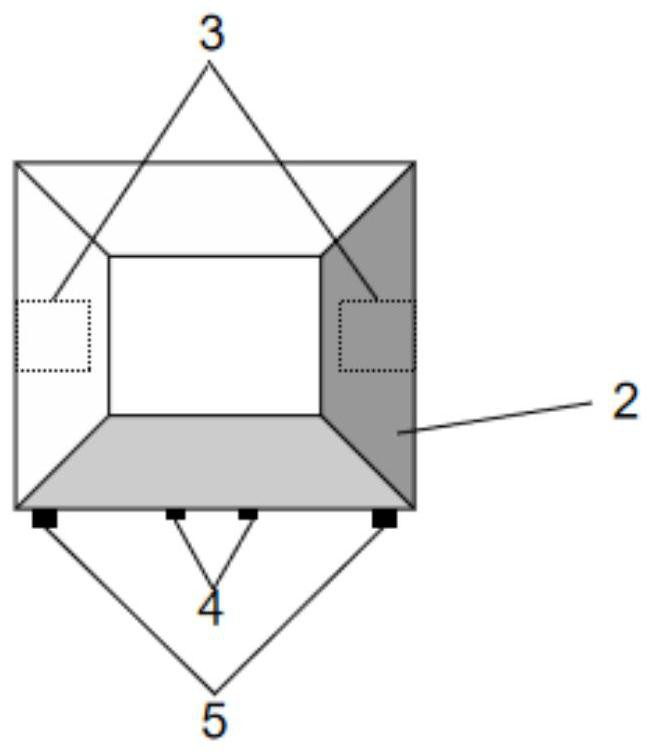

[0027] An unmanned aerial vehicle battery suitable for automatic replacement platforms, including a battery inner compartment 6 fixed on the unmanned aerial vehicle and a battery body 1 that can be matched and inserted into the battery inner compartment 6, wherein:

[0028] The side of the battery inner compartment 6 is formed with an opening 9 for the battery body 1 to enter and exit, and the bottom surface of the battery inner compartment 6 is fixed with a contact electrode 7 electrically connected to the drone;

[0029] The head end of the battery body 1 is formed with a self-correcting structure 2, and a paddle-type contact electrode 4 is fixed on the bottom surface of the battery body 1, and the paddle-type contact electrode 4 is in contact with the contact electrode 7 for power supply;

[0030] The corresponding surfaces of the battery inner compartment 6 and the battery body 1 are respectively provided with matching guide grooves 8 and guide bars 5, and the tail end of t...

Embodiment 2

[0033] In order to improve the self-correcting performance of the self-correcting structure 2, the battery inner compartment 6 is a housing with a rectangular parallelepiped structure, and the self-correcting structure 2 is a quadrangular truss structure formed on the battery body 1, and the quadrangular truss structure The four trapezoidal inclined surfaces are all guiding surfaces, and the rear part of the battery body 1 is a cuboid structure.

[0034] Since the automatic correcting structure 2 is a truss structure with trapezoidal slopes on all sides, during the pushing process, the position correction of the battery body 1 is automatically completed due to the thrust and the extrusion force of the slope; the automatic correcting structure is completely inserted into the battery inner compartment 6 Finally, at this time, the cross section of the rectangular parallelepiped battery 1 coincides with the cross section of the inner compartment 6 of the battery.

[0035] After th...

Embodiment 3

[0040] In order to facilitate the clamping of the manipulator, two embedded card slots 3 are provided, and the two embedded card slots 3 are respectively formed on two opposite sides of the tail of the battery body 1 . When the battery body 1 is inserted into the battery inner compartment 6, the embedded card slot 3 is located outside the battery inner compartment 6, which is convenient for the manipulator to grip.

[0041] More preferably, the two embedded card slots 3 are square slots, which cooperate with the square blocks fixed on the two fingers of the manipulator, so as to be convenient for the manipulator to grip. The inside of the finger is equipped with a block with the same inner diameter as the embedded card slot 3. The manipulator opens two fingers and moves to face the embedded groove. After the fingers are closed, the block is slowly inserted into the battery embedded groove 3. Complete the battery clamping, move the position of the manipulator to complete the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com