Production equipment and production process of steamed stuffed bun stuffing

A technology for production equipment and steamed stuffed buns, which is applied in mixed meat equipment, meat processing equipment, processed meat, etc. It can solve the problems of accumulated expired raw materials, inability to divide steamed stuffed buns, and hard fillings, so as to improve production efficiency and improve Taste, avoid accumulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

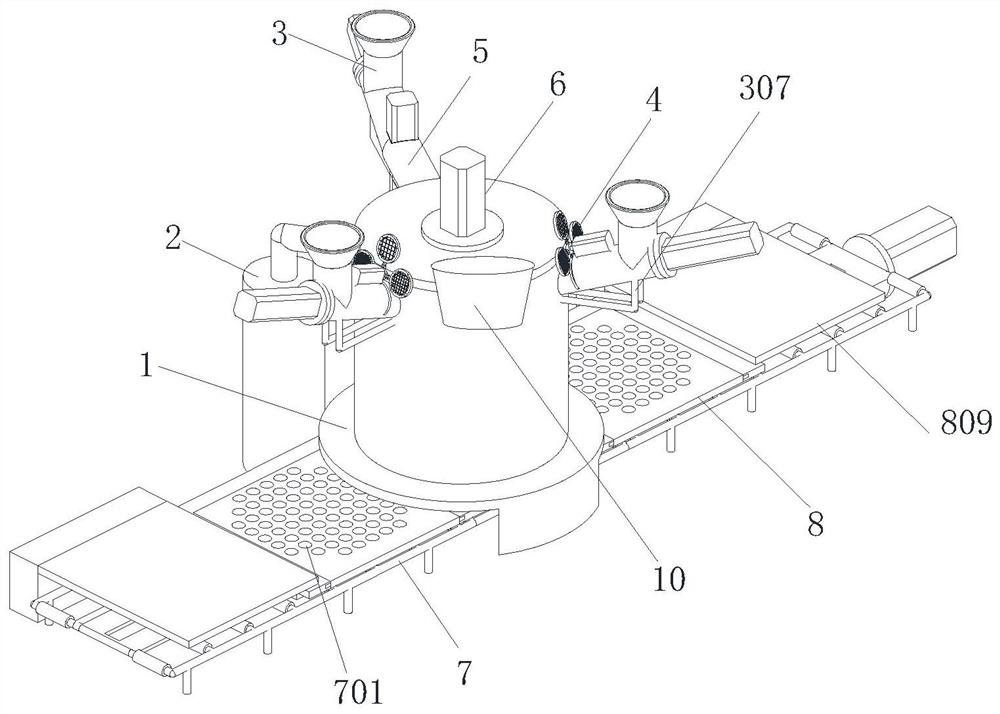

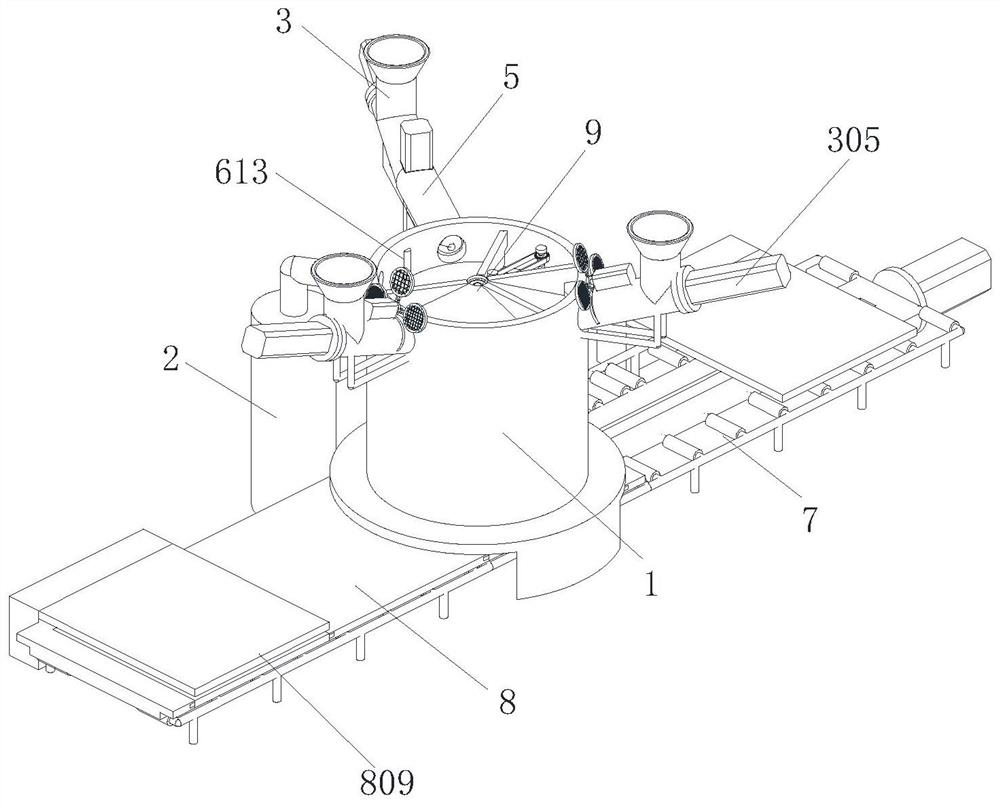

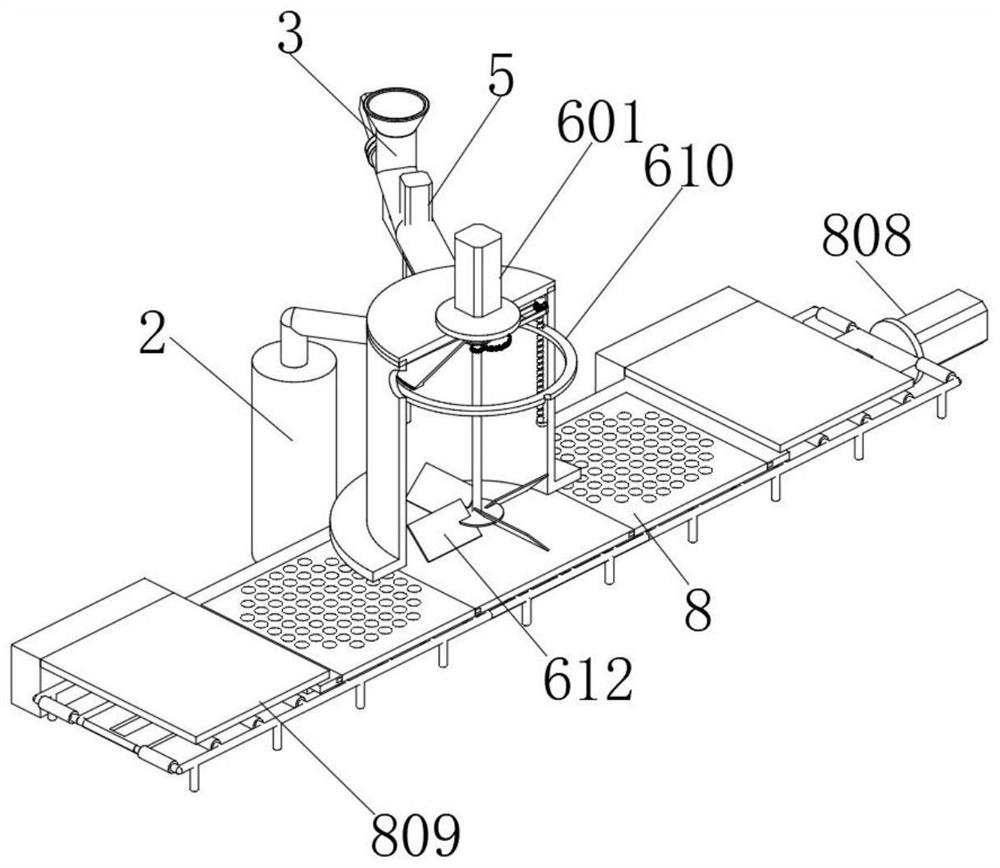

[0043] Such as Figure 1-Figure 8 As shown, the present invention provides a production equipment for stuffed buns, including a stirring tank 1, a cutting mechanism 3, an adjusting mechanism 4, a cleaning mechanism 6, a supporting mechanism 7 and a grouping mechanism 8, and the stirring tank 1 is installed on the supporting mechanism 7 Above, the upper end of the mixing tank 1 is provided with a protective cover 9, and the center of the protective cover 9 is provided with a through hole. The protective cover 9 forms multiple groups of feed ports through the partition plate and the mixing tank 1, and the side of the mixing tank 1 is connected with a negative pressure device. 2. The cutting mechanism 3 is installed on the mixing tank 1 for cutting raw materials, and the adjusting mechanism 4 is installed on the mixing tank 1 to adjust the cutting knife set inside the cutting mechanism 3, between the cutting mechanism 3 and the mixing tank 1 A pulverizer 5 is installed, and a cle...

Embodiment 2

[0057] This embodiment is improved on the basis of Embodiment 1. The production equipment for stuffed buns provided by this embodiment includes a stirring tank 1 with a protective cover 9 at the upper end of the inside. The stirring tank 1 is of a closed structure and installed On the upper side of the support mechanism 7, the side of the stirring tank 1 is respectively provided with a negative pressure device 2, a cutting mechanism 3, an adjusting mechanism 4 and an ice maker 10, and the cutting mechanism 3 is installed on the upper side of the stirring tank 1 for The whole piece of stuffing is cut into small pieces, and the adjustment mechanism 4 is installed on the upper side of the mixing tank 1 for adjusting the cutting knife provided inside the cutting mechanism 3, and a crushing device is installed between the cutting mechanism 3 and the mixing tank 1. Machine 5, the stirring tank 1 is equipped with a cleaning mechanism 6 for cleaning the inner wall surface of the stirri...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap