A kind of high-strength concrete and its production process

A high-strength concrete and ceramsite technology, applied in the field of concrete, can solve the problems of concrete self-shrinkage cracking, safety hazards, water-cement ratio reduction, etc., and achieve the effect of promoting cement hydration, increasing speed, and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

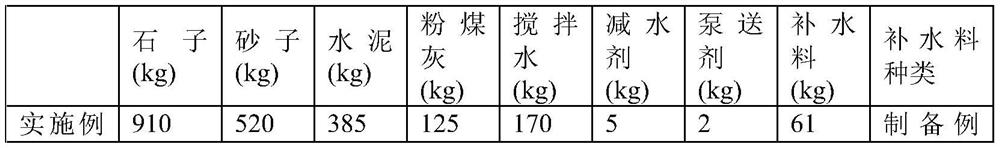

Examples

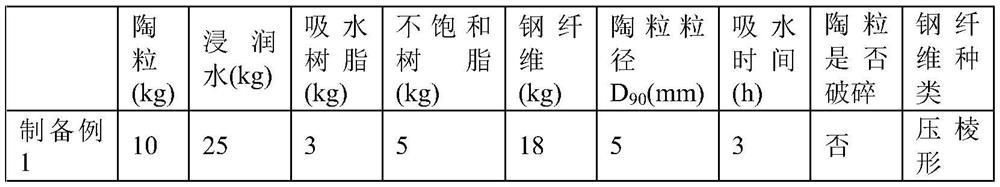

preparation example 1

[0035] S1, sieve the ceramsite, the particle size of the ceramsite is D 90 = 5mm, mix 10kg of ceramsite with 25kg of soaking water, and obtain water-storing ceramsite after absorbing water for 3 hours;

[0036] S2, the water storage ceramsite is pulled out from the soaking water and mixed with 3kg water-absorbing resin to obtain the water storage material;

[0037] S3, first mix the water storage material with 5kg of unsaturated resin, and then filter and separate the water storage material with the unsaturated resin from the unsaturated resin, so as to obtain the adhesive;

[0038] S4. Mix the adhesive material with 18kg of pressed prismatic steel fibers to obtain a hydrating material.

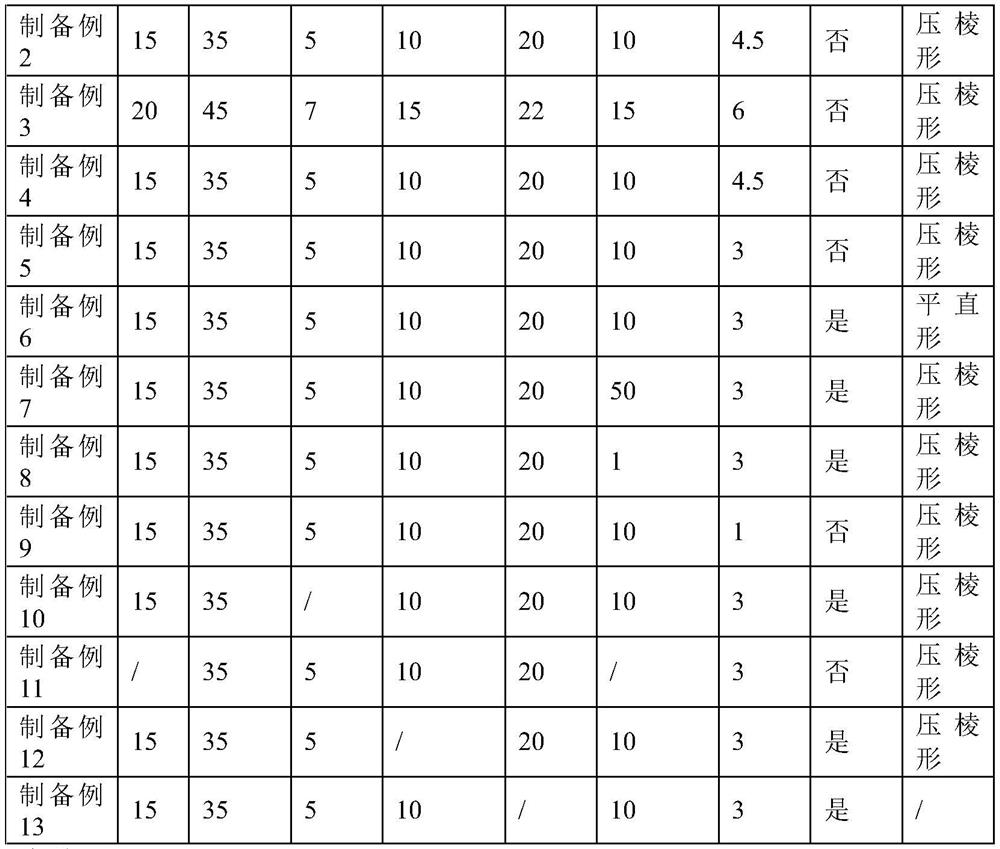

preparation example 2

[0040] S1, sieve the ceramsite, the particle size of the ceramsite is D 90 =10mm, mix 15kg of ceramsite with 25kg of soaking water, and obtain water-storing ceramsite after the ceramsite absorbs water for 4.5 hours;

[0041] S2, the water storage ceramsite is taken out from the soaking water and mixed with 5kg water-absorbing resin to obtain the water storage material;

[0042] S3, first mix the water storage material with 10kg of unsaturated resin, and then filter and separate the water storage material with the unsaturated resin from the unsaturated resin, so as to obtain the adhesive;

[0043] S4. Mix the binder with 20kg of pressed prismatic steel fibers to obtain a water replenishing material.

preparation example 3

[0045]S1, sieve the ceramsite, the particle size of the ceramsite is D 90 =15mm, mix 20kg of ceramsite with 45kg of soaking water, and obtain water-storing ceramsite after absorbing water for 6h;

[0046] S2, the water storage ceramsite is pulled out from the soaking water and mixed with 7kg of water-absorbent resin to obtain the water storage material;

[0047] S3, first mix the water storage material with 15kg of unsaturated resin, and then filter and separate the water storage material with the unsaturated resin from the unsaturated resin, so as to obtain the binder;

[0048] S4. Mix the adhesive material with 22kg of pressed prismatic steel fibers to obtain a water-replenishing material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com