Movable trolley for cleaning subway tunnel

A technology for tunnels and trolleys, used in safety devices, mining equipment, earth-moving drilling, etc., can solve the problems of inability to clean the surface of facilities, low cleaning efficiency, and inability to clean the inner wall of subway tunnels, so as to achieve large coverage and reduced cleaning operations. Labor intensity, the effect of speeding up the cleaning progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

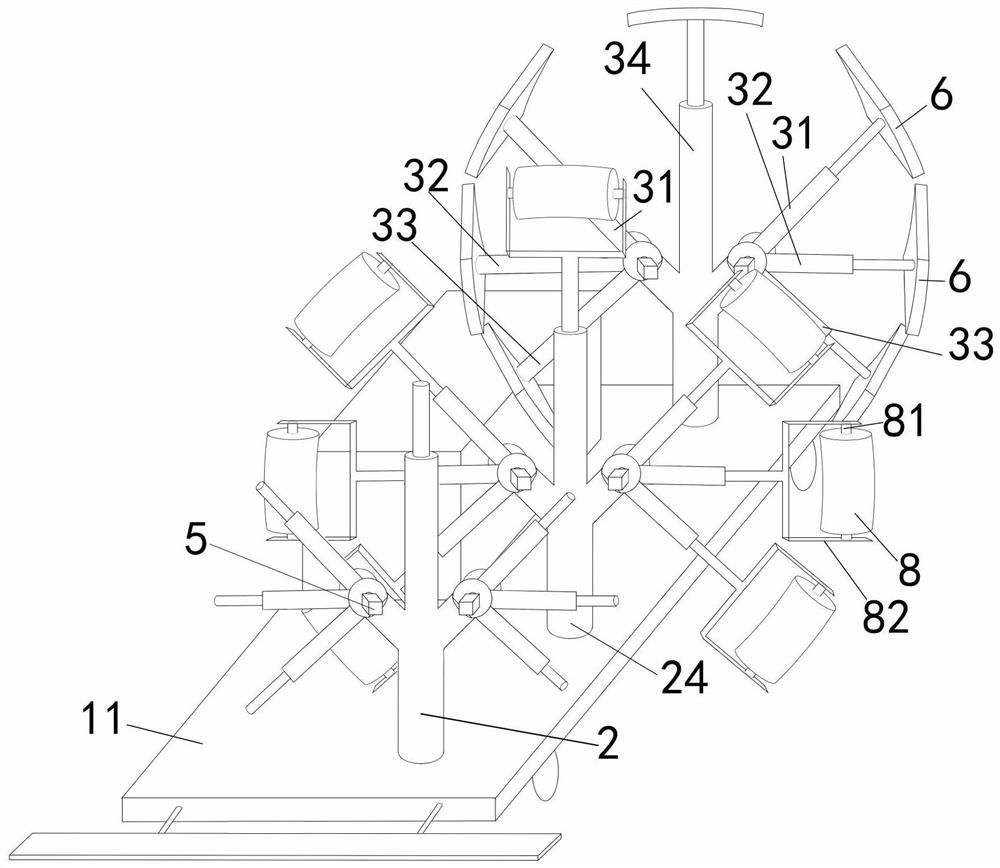

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

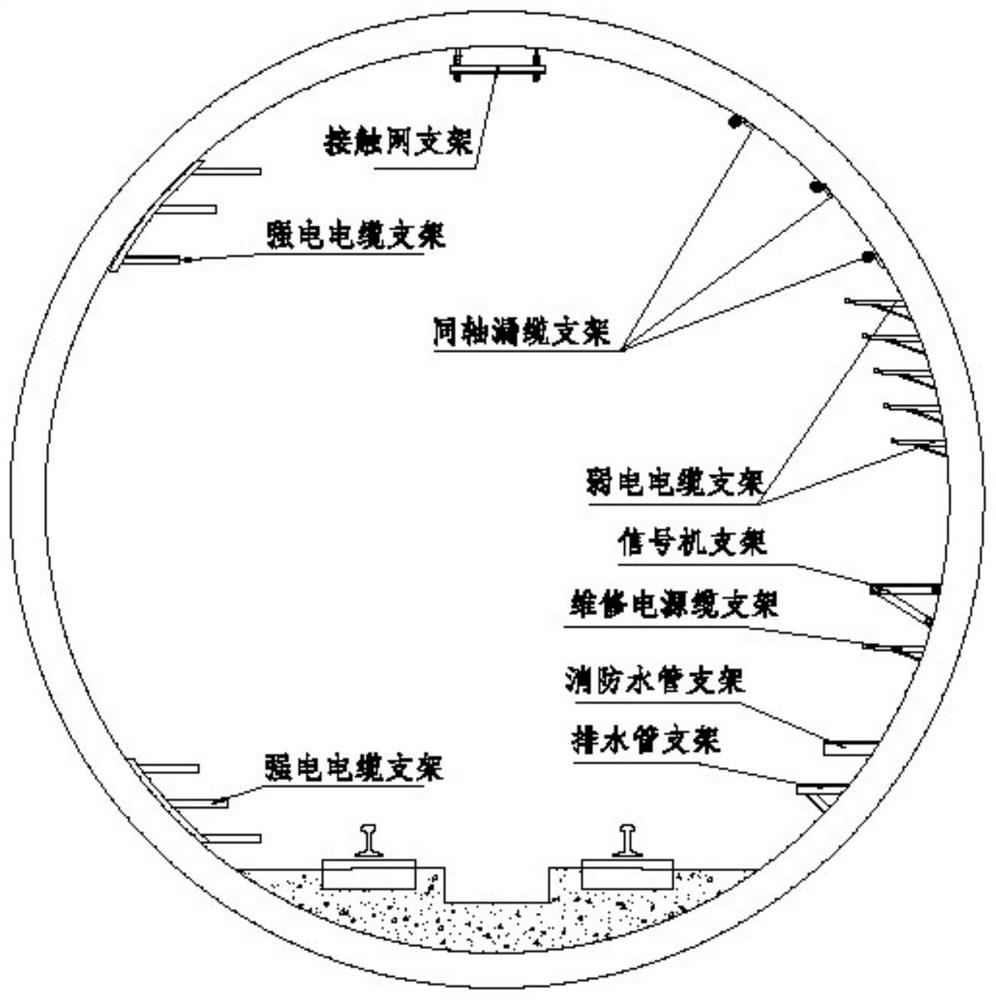

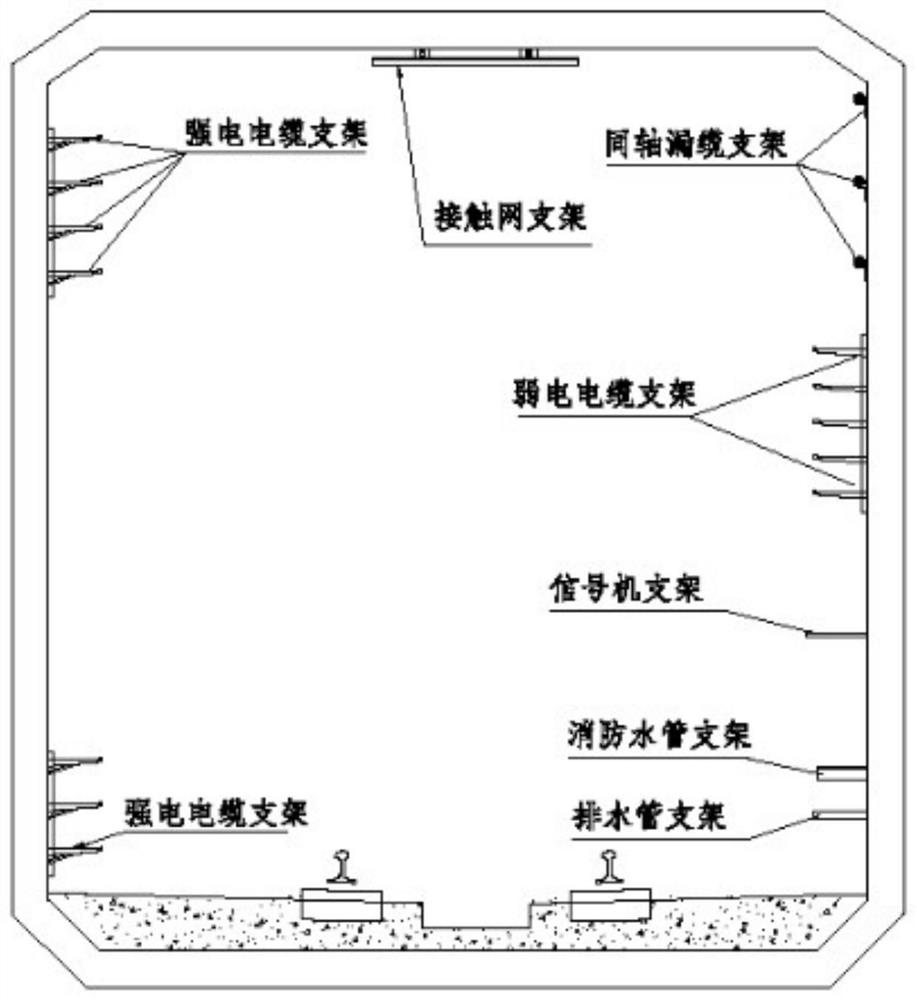

[0034] Such as image 3 As shown, the present invention is a mobile trolley for subway tunnel cleaning, including a traveling car body and a cleaning assembly; the traveling car body includes a base plate 11 and a traveling wheel arranged below the base plate 11, and the traveling wheel moves on the track through a traveling motor As the mobile carrier of the device of the present invention, the main function of the traveling vehicle body is to facilitate the mobile operation of the device of the present invention, because the tunnel interior itself is just laid with track, so the traveling vehicle body just can utilize this track to advance. image 3 In order to facilitate the representation, the cleaning plate 6 on the end cleaning bracket 2 and the connection between the water spray pipeline and the cleaning plate 6 are omitted. P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com