Powder metallurgy synchronizer gear hub

A technology of powder metallurgy and synchronizer, which is applied in the direction of clutches, mechanically driven clutches, engine components, etc., can solve problems such as vibration, increased friction of synchronizer gear hubs, and inability to effectively and stably mesh, so as to avoid vibration impact, Reduces frictional damage and facilitates engagement of buckles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

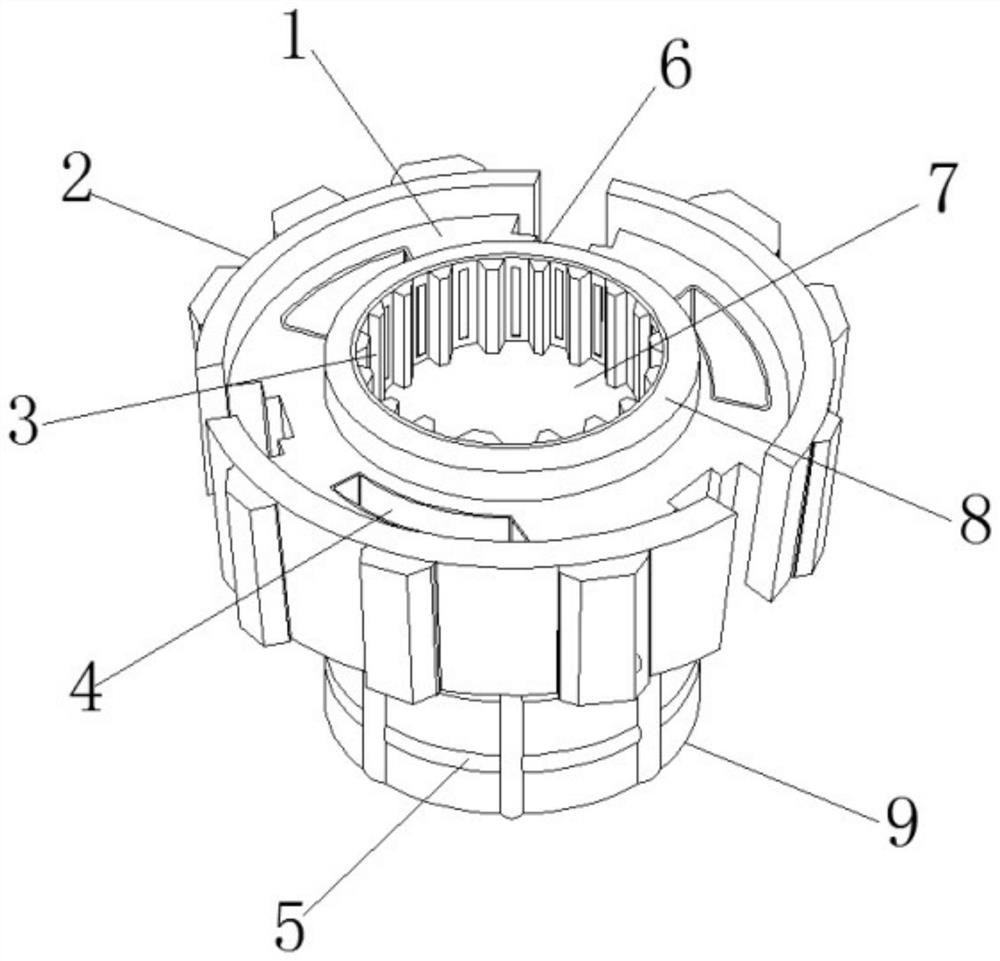

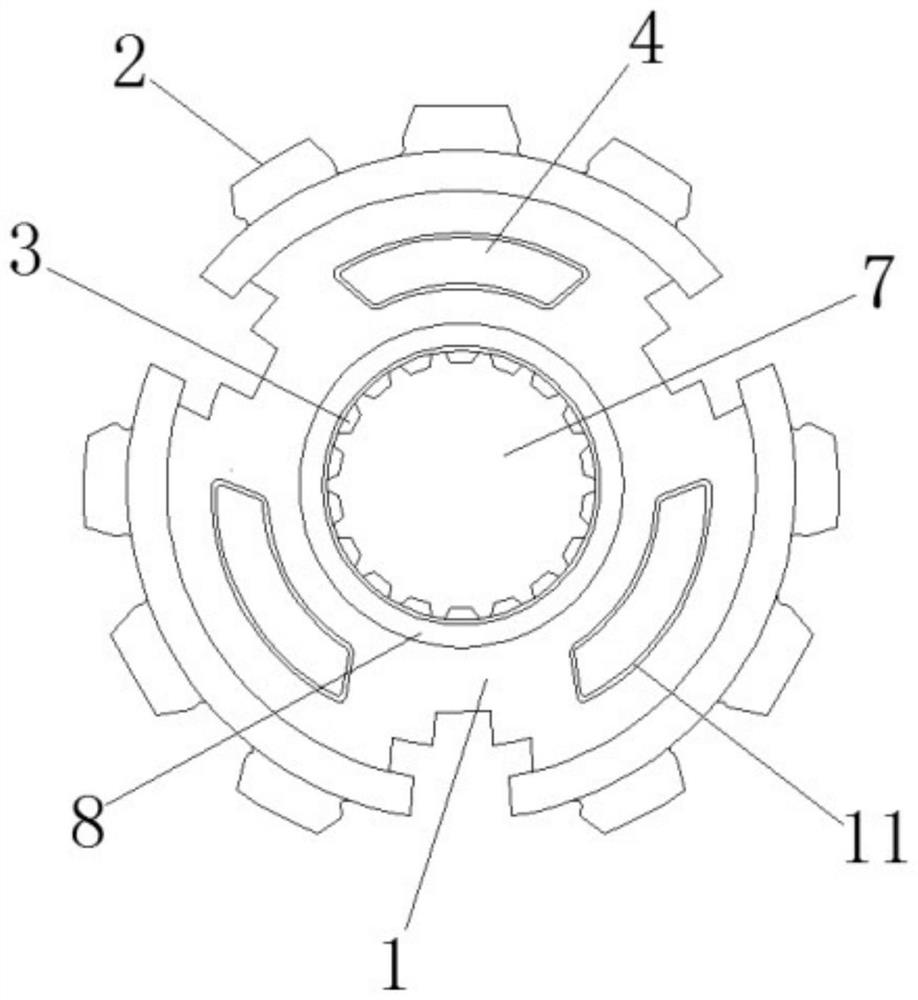

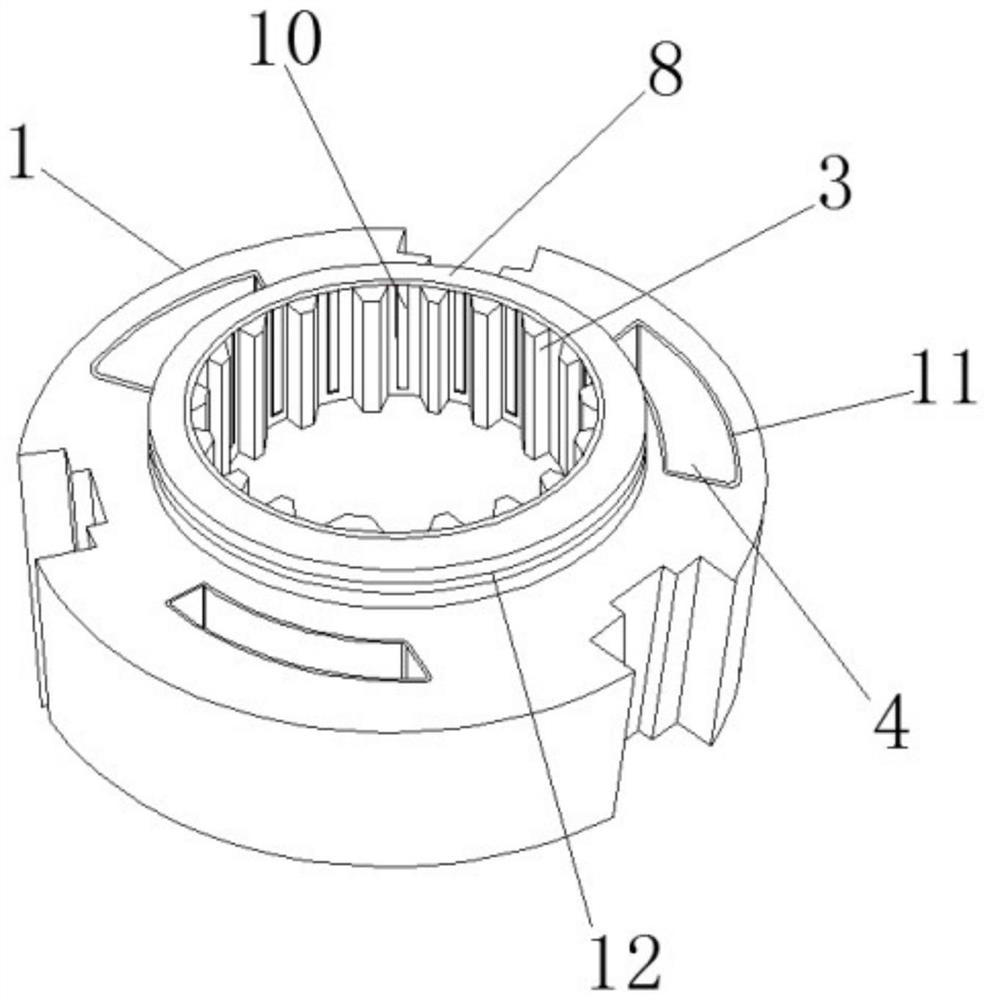

[0036] EXAMPLIC: The hub body 1 is mainly fixed on the inner ribs of the inner ring 8 in the inner ring 8 in the sleeve, which is effectively fixed on the transmission shaft of the powder metallurgy synchronizer, and the inner spline of the hub is in the intermediate intermediate spline card. The groove 7 is oriented with the positioning guide of the positioning guide, and the eighteen positioning guide grooves 10 is symmetrically distributed in the inner side of the hub, thereby forming a tight fit with the powder metallurgical synchronizer drive shaft spline to make the hub The inner spline 3 and the drive shaft spline cannot have a relative rotation of fine angles in the circumferential direction, which avoids the jitter impact during operation.

[0037] The three sectors of the hub body 1 reduce the groove 4 space, so that the overall weight is effectively reduced, so that the overall friction force is reduced, and the angle of three sector reduction grooves 4 is disposed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com