Automatic tea baking equipment and tea baking method thereof

A technology for roasted tea and equipment, which is applied in the field of tea production equipment, can solve the problems of difficult control, smoke and burnt smell in the finished product, artificial, etc., and achieves the effects of rich taste and strong adsorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

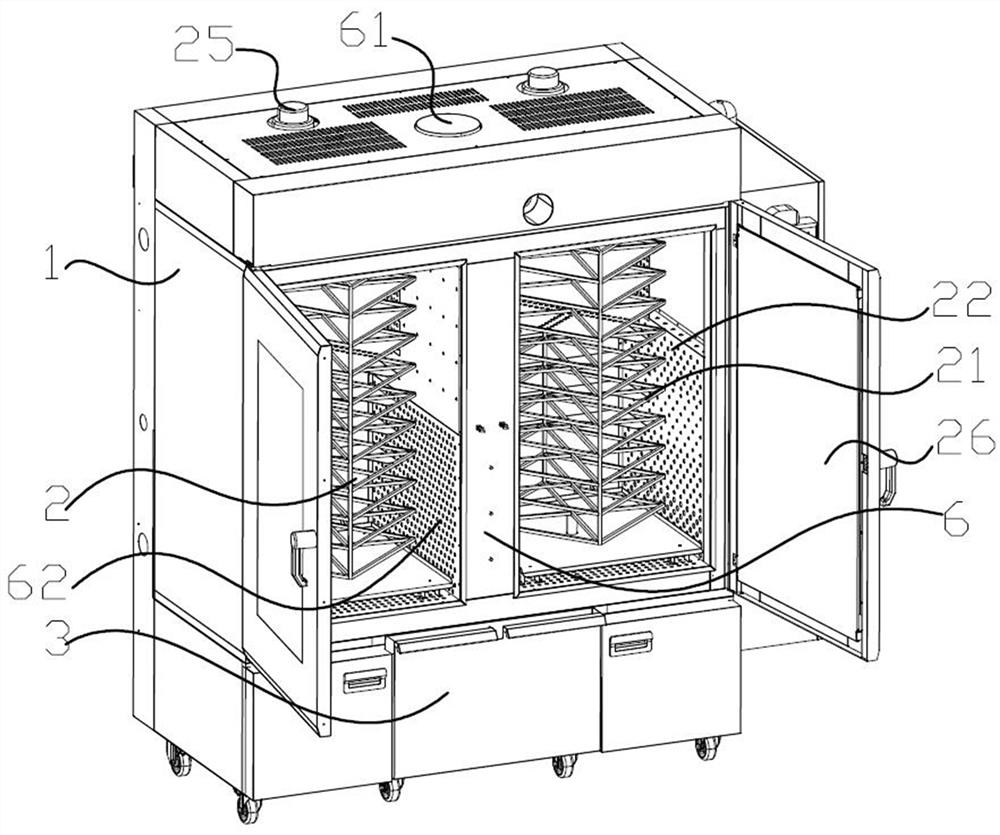

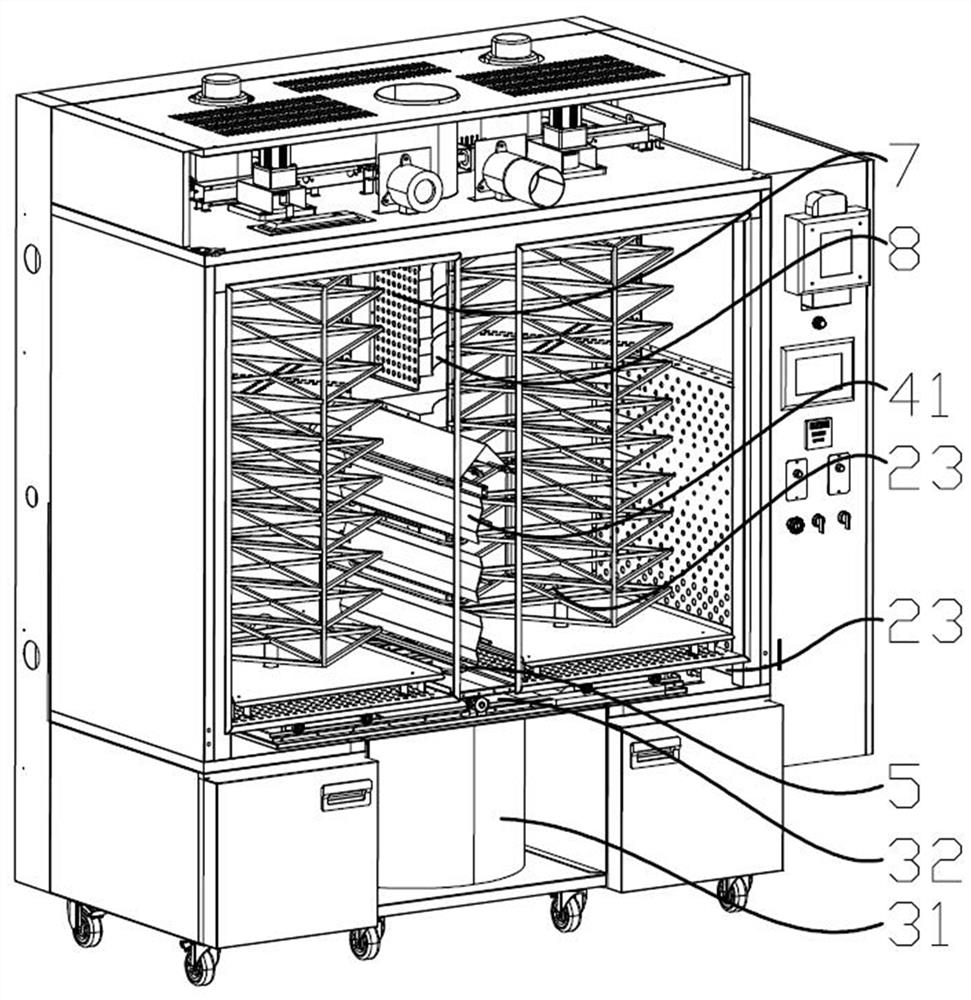

[0032] An automatic tea roasting device, as shown in the figure, includes an outer casing 1, a roasted tea module 2, a charcoal roasting module 3, a first gas flow channel 4, and a heating assembly 5; the roasted tea module 2; the roasted tea module 2 includes a support The frame 21 and the first porous plate 22, the support frame 21 is used to place tea leaves, the first porous plate 22 is arranged on the side of the support frame 21, and the first porous plate 22 is arranged with through holes for the passage of gas. like figure 1 As shown, there are two roasted tea modules 2, and the two roasted tea modules 2 are distributed left and right, and more than two roasted tea modules 2 can also be provided. The first gas flow channel 4 is provided with a second gas flow channel 6 in the center. The automatic flow of airflow is adopted instead of the way of blowing air, in order to maintain the quality of tea and ensure its flavor. The through holes of the first porous plate 22 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap