Additive-free cooked ready-to-eat whole-grain coarse cereal product and production process of product

A technology of whole grains and no additives, applied in the field of miscellaneous grain products, can solve the problems of long shelf life and the difficulty of satisfying the taste of miscellaneous grain products at the same time, and achieve the effects of prolonging the shelf life, benefiting human health and improving taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

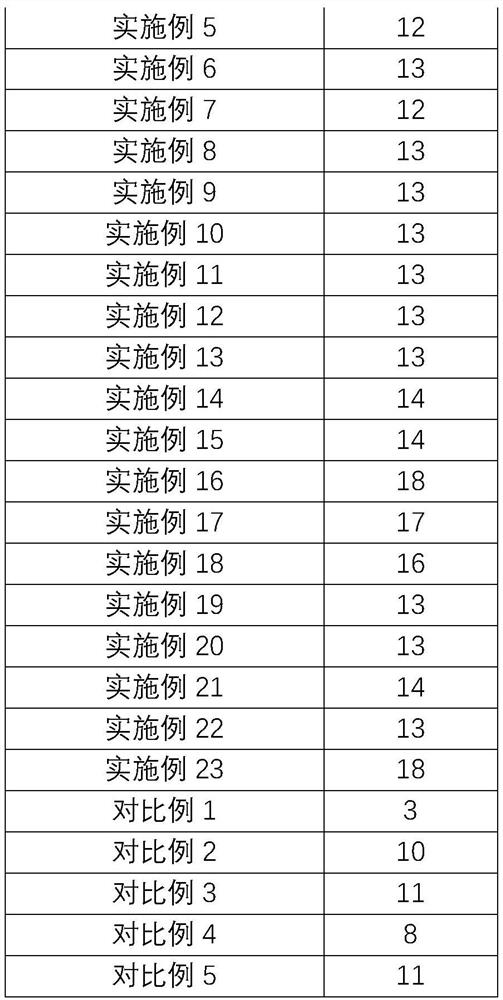

Examples

Embodiment 1

[0040] A ready-to-eat non-additive-cooked bagged cereal product, the raw materials are composed of 2kg peanuts, 2kg soybeans, 1.5kg red beans, 1kg oats, 1kg job's tears, 1kg black rice, 1kg black beans and 0.5kg sesame, and are made by the following steps :

[0041] Step 1, screening raw materials: removing impurities and damaged raw materials;

[0042] Step 2, soaking: Soak the raw materials separately in tap water, the water temperature is controlled at 25°C, the soaking time is 5 hours, and the moisture content of the raw materials is 40% after soaking;

[0043] Step 3, cleaning: wash the soaked raw materials with tap water respectively, the temperature of the water is 30°C, and the cleaning time is 2 minutes;

[0044] Step 4, mixing: mix the cleaned raw materials evenly;

[0045] Step 5, blanching: put the mixed raw materials into hot water for blanching, the temperature of the hot water is 92°C, and the blanching time is 10 minutes;

[0046] Step 6, cooling: pick up th...

Embodiment 2

[0051] A ready-to-eat non-additive-cooked multi-cereals product differs from Example 1 in that the soaking water temperature in Step 2 is controlled at 32° C. and the soaking time is 4 hours.

Embodiment 3

[0053] A ready-to-eat multi-grain product cooked without additives, differs from Example 1 in that the soaking water temperature in step 2 is controlled at 40° C., and the soaking time is 3 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com