Monomer adsorption rotating tower

A turret and monomer technology, which is applied in gas treatment, dispersed particle separation, membrane technology, etc., can solve the problems of high equipment manufacturing consumables, long cycle, and high replacement cost of adsorption runners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

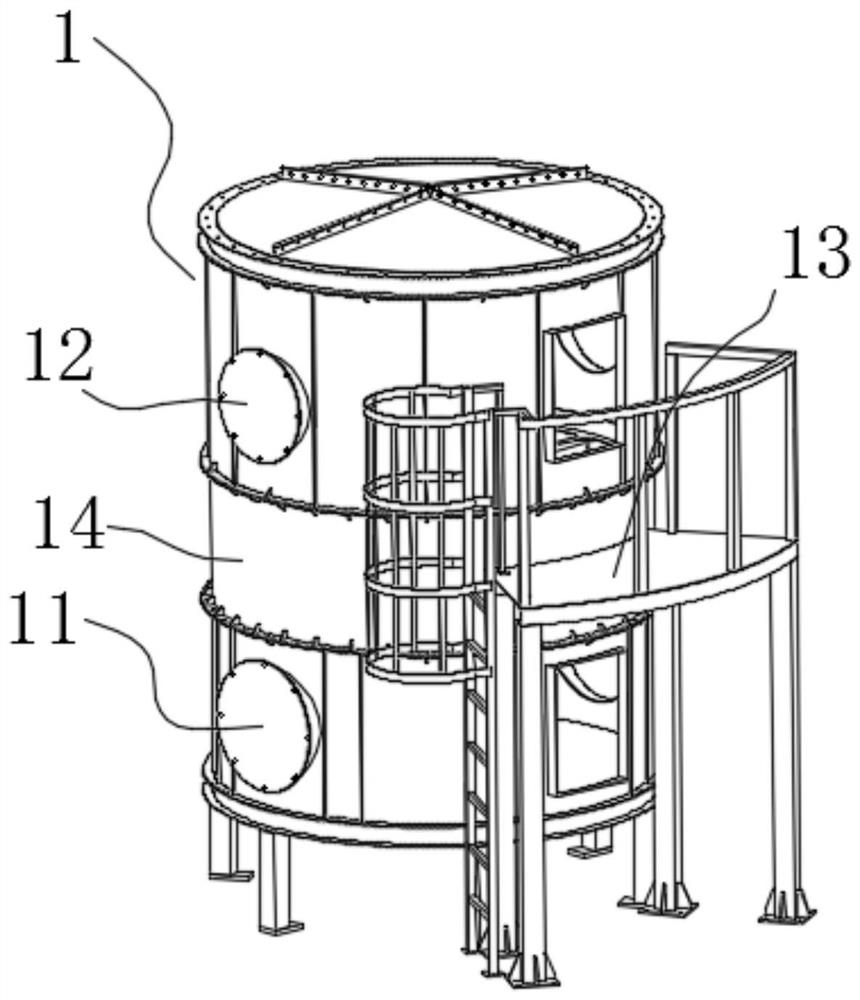

[0029] Example 1: See figure 1 , the present invention provides a single adsorption turret, comprising an adsorption turret 1 and a desorption device 10 connected to the adsorption tower 1 (the function of the desorption device 10 in this embodiment is to transport the medium used for desorption to the adsorption turret. Carry out desorption in tower 1, mainly comprise blower fan, hot air heater). In addition, the principle of hot air desorption is utilized in this embodiment, which does not limit the scope of this embodiment.

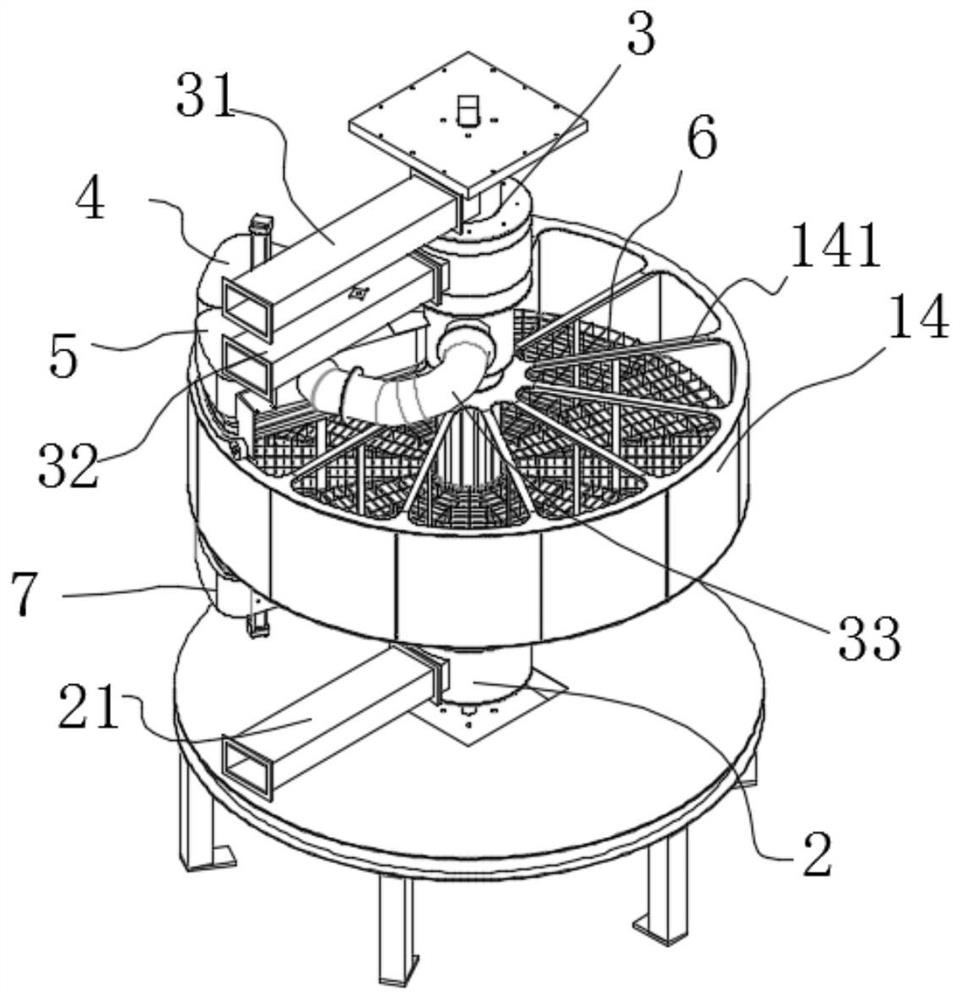

[0030] Structural reference of adsorption brick tower 1 figure 2 As shown, it includes a tower body 14 with an adsorption cavity inside and an adsorption body 6 located in the adsorption cavity; the air inlet 11 and the air outlet 12 on the tower body 14 communicate with the adsorption cavity, and the exhaust gas enters from the air inlet 11 and passes through The adsorbent 6 is discharged through the air outlet 12 after being adsorbed. In addition...

Embodiment 2

[0061] Embodiment 2: Based on the general inventive concept of Embodiment 1, in this embodiment, the adsorption body 6 is set to be rotatable, and the valve body structure / each wind box used for desorption and cooling is fixedly arranged on its rotation path, function can also be realized.

[0062] Finally, it is worth mentioning that in Embodiment 1, the structure of each bellows is set as a rotary type, which has a small load on the motor or other power systems and runs stably; while Embodiment 2 is feasible, but in actual implementation Also consider the problem of driving load.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com