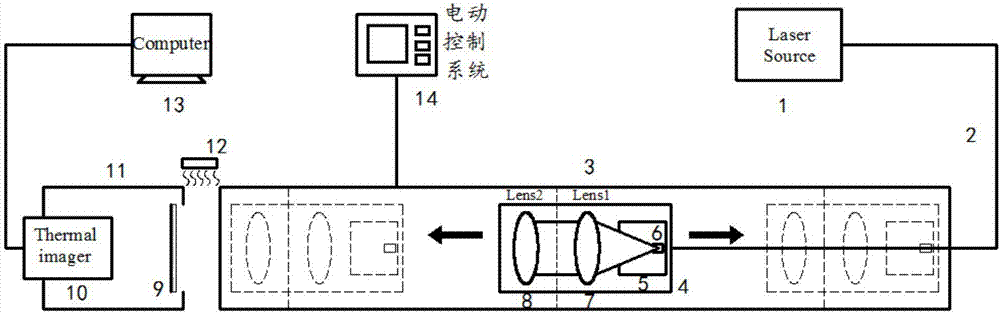

A laser beam quality measuring device output from an optical fiber

A technology of laser beam quality and beam quality, which is applied in measuring devices, optical radiation measurement, photometry, etc., can solve the problems of small dynamic range and low damage threshold of CCD detectors, so as to avoid distortion and wide measurable laser wavelength The effect of less range and error factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

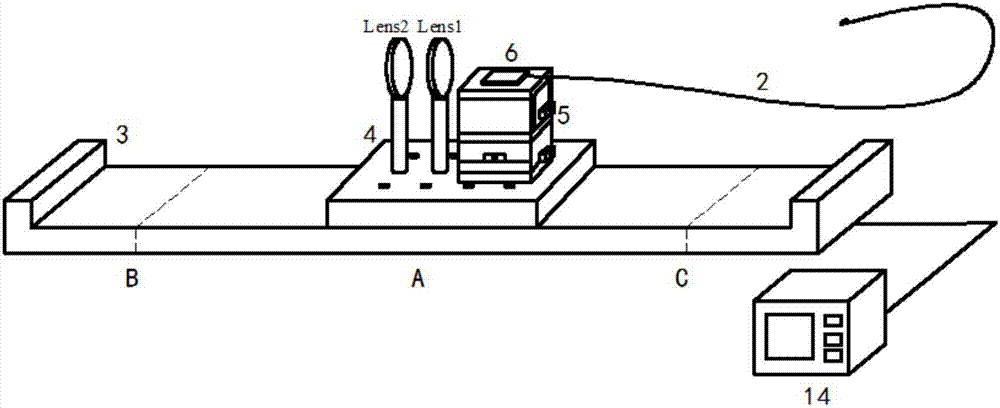

Method used

Image

Examples

Embodiment 1

[0088] Laser 1 is a semiconductor laser with an output laser wavelength of 976nm, and optical fiber 2 is a 105 / 125 passive optical fiber. Laser 1 outputs 976nm laser after coupling with optical fiber 2. During the measurement, the output power is set to 4W, the data and its fitting results are as follows Figure 5a is the beam quality factor of the laser output from the fiber in the x direction within the beam section Figure 5b is the beam quality factor of the laser output from the fiber in the y direction of the beam section Wherein, the abscissa z is the position coordinate of the beam section on the optical axis, the ordinate Laser beam width is the beam width, and the curve is the fitting curve of the beam width. The beam quality measurement of the laser is:

Embodiment 2

[0090] Laser 1 is a fiber laser, pumped by a semiconductor laser with a wavelength of 976nm, 20 / 400 ytterbium-doped fiber 2 outputs a laser with a wavelength of 1070nm. During the measurement, the output power is set to 4W. The data and its fitting results are as follows Figure 6a is the beam quality factor of the laser output from the fiber in the x direction within the beam section Figure 6b is the beam quality factor of the laser output from the fiber in the y direction of the beam section Among them, the abscissa z is the position coordinate of the beam section on the optical axis, the ordinate Laserbeam width is the beam width, and the curve is the fitting curve of the beam width. The beam quality measurement of the laser is:

[0091] Compared with existing products, this implementation process has a simple optical path, no attenuation, convenient operation, stable repeated measurement results, and a greatly shortened measurement cycle to 20 minutes. According to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com