Slip ring U-screw machining tool and using method

A slip ring and screw technology, which is applied in the field of slip ring processing, can solve the problems that the electric slip ring is easy to slide on the motor shaft, the installation stability of the electric slip ring and the motor shaft is not good, and affects the practicality, so as to achieve the stability of fixed installation High, good fixing effect, fast positioning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

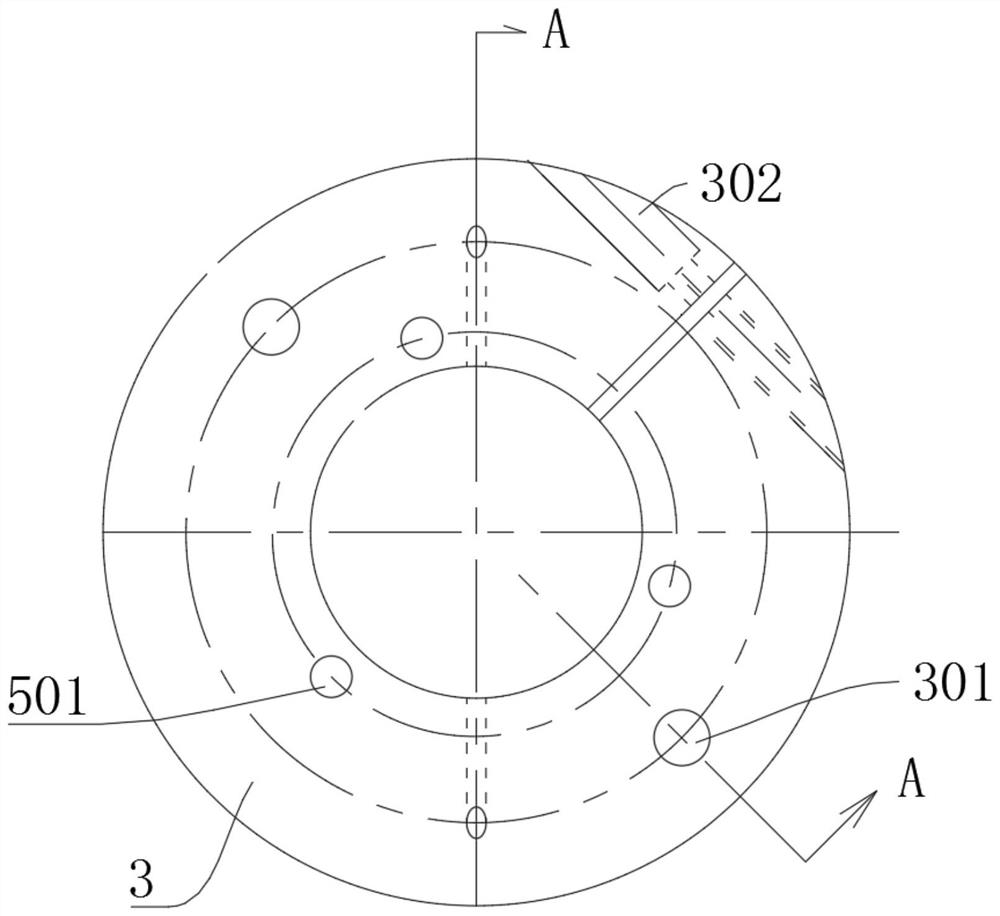

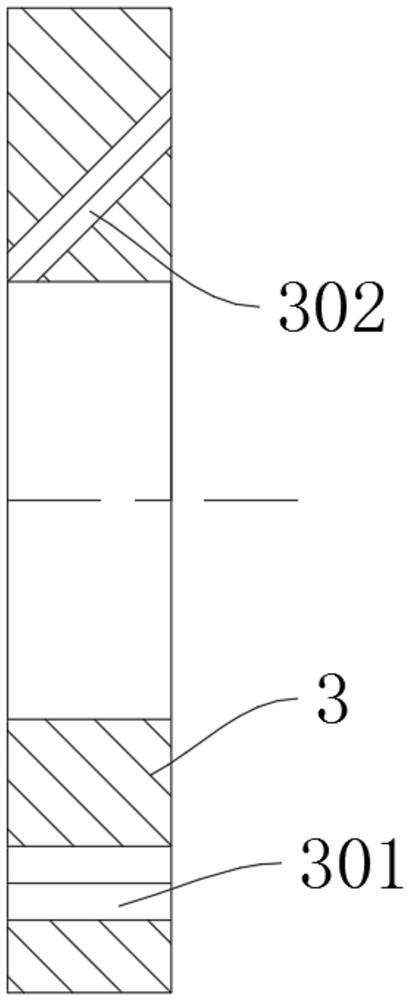

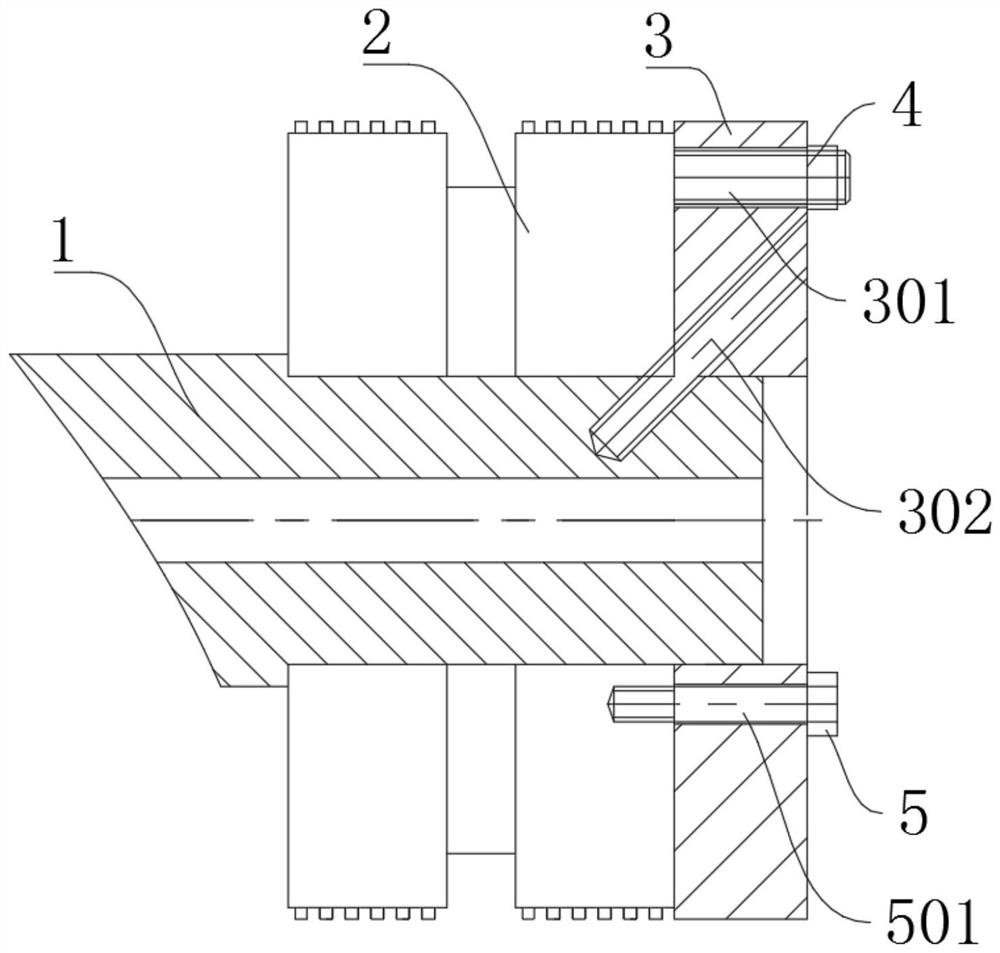

[0025] Refer Figure 1-3 Slip ring riding screw machining tooling, comprising: a motor shaft, the center of the slip ring shaft 2, the socket member; sheathing slip ring member on the motor shaft 2; slip-ring sleeved on the motor shaft 1 is fixed spiro hole positioning plate 3, the slip ring for clamping the fixing member 2; wherein the slip ring element is provided between the positioning member 32 and the sliding ring retainer screw positioning plate processing, is to be understood that the positioning member comprising: a positioning plate die hole 301 provided on the sliding ring fixing screw machining positioning plate 3; slip ring bolt connection 4, is fixedly connected to the slip ring element 2, inserted in the die plate locating holes 301, the positioning member is provided with two sets of symmetrical, in the slip ring 3 fixed to the socket screw holes when the plate is positioned on the working axis motor 1, the slide ring is fixed screw machining positioning plate 3 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com