Telescopic protective cover and forming method thereof

A molding method and technology of protective cover, applied in maintenance and safety accessories, metal processing machinery parts, metal processing, etc., can solve problems such as cracking and leakage of protective cover.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

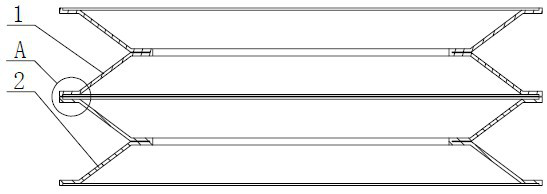

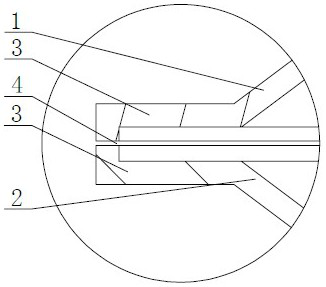

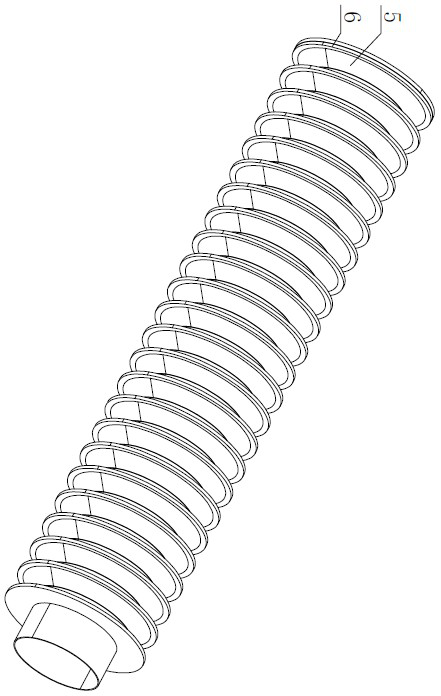

[0029] The retractable protective cover of the present invention includes protective covers of other shapes such as cylindrical ring-shaped protective covers, such as Figure 3~5 As shown, the protective cover of this embodiment is integrally processed and formed. First, a whole piece of cylindrical hollow elastic body is selected. The elastic body can be rubber, silica gel, TPU, rubber, PVC, PP, nylon, plastic, etc., with certain flexibility. and cuttable material. The length of the elastic body is the length of the ultimate compression state of the actual finished product of the columnar protective cover, and the elastic body is a monolithic material without any splicing or breaking point. Fix the elastic body on a rotating device that can rotate the elastic body along the axial direction, and then start the rotating device. During the rotation of the elastic body, use a cutting device such as a disc knife or a laser knife to cut the outer surface 6 of the entire elastic bod...

Embodiment 2

[0033] The present invention also includes telescopic protective covers of other shapes, and the cross section of the protective cover can be circular, arc-shaped, hollow polygonal, or rectangular. Elastomers, also cut the outer surface at equal distances first, and then cut the inner surface at equal distances. When cutting, ensure that the cutting depth remains unchanged. The cutting depth is 10-95% of the thickness of the cutting seam. The square protective cover will appear at the right angle. The cut rounded corners further enhance the axial tensile capacity of the retractable protective cover.

Embodiment 3

[0035] The cutting tool and the cutting path of the present invention can be flexibly determined according to the elastic body to be processed, for example, multiple parallel blades can be used to cut in at the same time, so as to improve the forming efficiency. Or the tool rotates at high speed and cuts into the fixed elastic body along the set track.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com