Prestressed concrete pipe pile curing device

A concrete pipe pile and prestressing technology, which is applied in the field of prestressed concrete pipe pile maintenance devices, can solve the problems of poor maintenance effect and achieve the effects of effective heat energy saving, uniform heat distribution, and heat recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

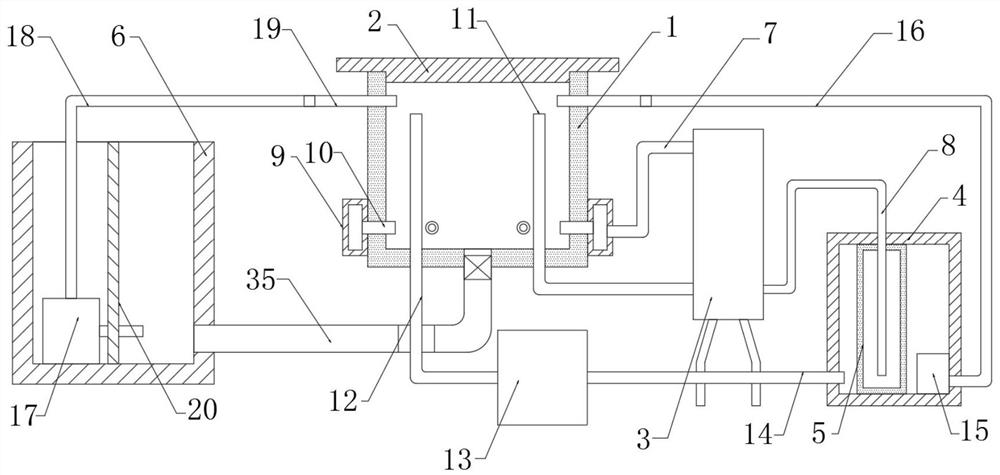

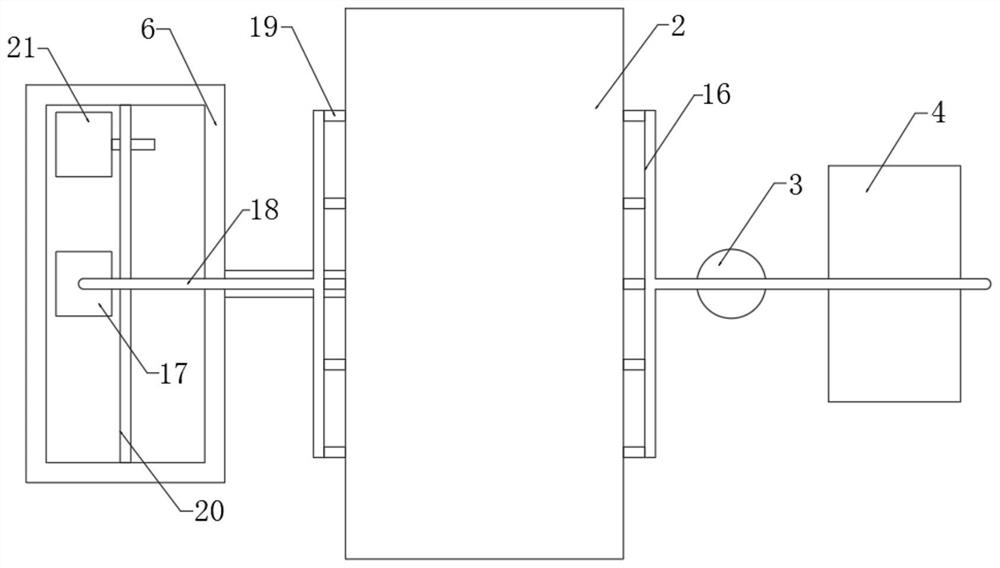

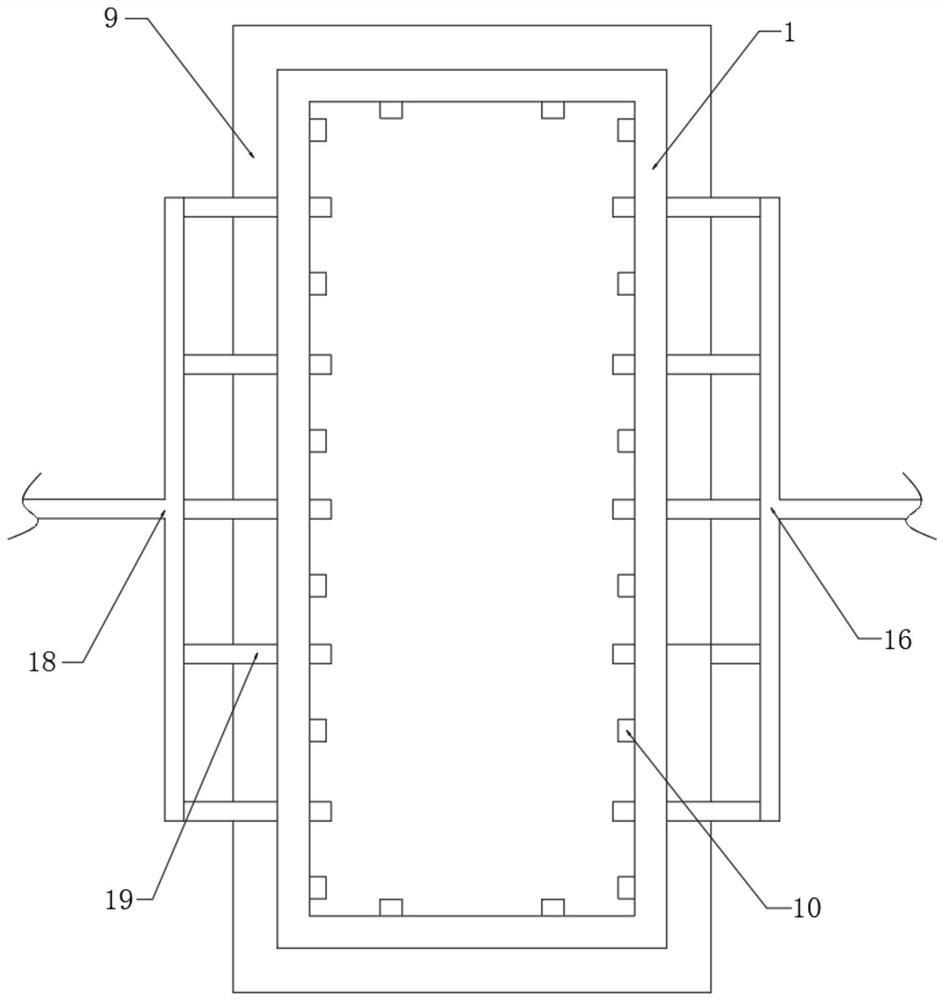

[0027] refer to Figure 1-5 , a prestressed concrete pipe pile maintenance device, comprising a maintenance tank 1, a steam generator 3, a preheating tank 4 and a cooling water tank 6, the upper end of the curing tank 1 is provided with a sealing cover 2, and the gas outlet of the steam generator 3 is connected with The steam pipe 7, the steam pipe 7 communicates with the interior of the curing tank 1 through the ring spray mechanism, the water inlet of the steam generator 3 is connected with a steam pumping pipe 8, the steam pumping pipe 8 communicates with the preheating box 4, and the preheating box 4 is internally provided There is a heat recovery mechanism, and the bottom of the maintenance tank 1 is inserted with a return pipe 11 and a preheating pipe 12. The preheating pipe 12 communicates with the preheating box 4 through a timing mechanism, and the return pipe 11 communicates with the steam generator 3. A recovery pipe 35 communicating with the inside of the cooling w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com